Agriculture

February 1, 2024

Piteba Oil Expeller Press

Read SolutionImplemented by

Piteba

Updated on September 10, 2024

·Created on June 17, 2014

The Alvan Blanch Oil Expeller Press XP100-E is a cold press machine used for extracting oil from oilseeds like rapeseed and linseed

The Alvan Blanch Oil Expeller Press XP100-E is an automatic oil expeller for cold pressing oilseeds like rapeseed, linseed and others. The product can expel oil from seeds at a feedstock rate of approximately 150 – 400 kg/hr.

This product has been discontinued based on our latest update.

Target SDGs

SDG 8: Decent Work and Economic Growth

Market Suggested Retail Price

$12,190.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Alvan Blanch Development Company LtdInterview with representative

Competitive Landscape

Direct competitors include Piteba Oil Expeller Press.

Regions

Africa

Manufacturing/Building Method

The Alvan Blanch Oil Expeller Press XP100-E is built using components such as proximity sensors, bar magnet grid, precision cast press plates and others.

Intellectural Property Type

Patent

User Provision Model

All components can be ordered through Alvan Blanch – and can be sent out directly by DHL or airfreight – dimensions/weight dependentInterview with representative

Distributions to Date Status

About 40 Interview with representative

Feedstock types

Oilseeds like rapeseed, sunflower, linseed, etc.

Volume of oil produced (L)

250-300

Capacity: Feedstock rate (kg/hr)

150-400

Power source

Motorized

Motor drive power (kW)

9.2

Design Specifications

The Alvan Blanch Oil Expeller Press is designed such that the seed is placed under increasing pressure as it is conveyed through a tapered chamber. Because of the high level of compression (and pressure generated temperature) oil is expelled through a set of rings. The residual solid matter is conveyed to the end of the press and falls away as thin strips of ‘oilcake’.

• Compresses oilseed drape at 150 - 400 kg/hr

• No switches or basic control panel

• Dimensions (LxWxH) (cm): 155 x 112 x 180

• XP100E model has a 9.2 kWh motor. Interview with representative

| SPECIFICATIONS | |||||

| Models | Capacity (Typical) | Drive kW | Length mm | Width mm | Height mm |

| XP100 | 150 kg/hr | 9.5 | 1550 | 1120 | 1800 |

| XP300 | 400 kg/hr | 23.0 | 2035 | 1276 | 1937 |

Key features:

Technical Support

Technical support is provided by Alvan Blanch

Replacement Components

Choke ring, multiple segment pressing screw, set of 17 cast iron replaceable platesInterview with representative

Lifecycle

10-15 years

Manufacturer Specified Performance Parameters

The Alvan Blanch Oil Expeller Press is designed to expel approximately 250 to 300 liters of oil from one tonne of rapeseed, depending upon the original oil content, moisture content and cleanliness of the sample

Vetted Performance Status

Unknown

Safety

Unknown

Complementary Technical Systems

If a generator is used to power the press - the press should be fitted with a speed controller. A voltage monitoring system is needed to avoid damage to the inverter.

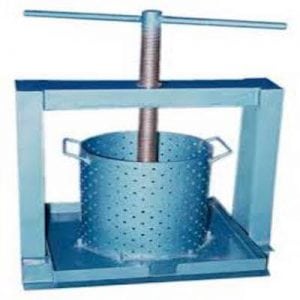

The XP100E gives crude oil. In order to get processed oil, you would need a filter press, pump, settling tanks, etc.

Additional attachments include: Temperature Adjustment Chamber, Oil Pump, Feed Hopper, Proximity Sensor, MPC Pre-Cleaner, MPC Support Frame, IBC Tank, Primary Settling Tank Interview with representative

Academic Research and References

Orhevba, B. A., Chukwu, O., Osunde, Z. D., and Ogwuagwu, V., 2013, Influence of moisture content on the yield of mechanically expressed neem seed kernel oil. Academic Research International. 4(5) pp 252-257.

Bamgboye, A. I., and Adejumo, A. O. D., 2007, Development of a sunflower oil expeller. International Commission of Agricultural Engineering, 9: pp 1-7.

Nelson, A. I., Wijeratne, W. B., Yeh, S. W., Wei, T. M., and Wei, L. S., 1987, Dry extrusion as an aid to mechanical expelling of oil from soybeans. Journal of the American Oil Chemists’ Society, 64(9), 1341-1347.

Compliance with regulations

Unknown

Other Information

Agriculture

February 1, 2024

Implemented by

Piteba

Agriculture

September 11, 2024

Implemented by

Alvan Blanch

Agriculture

February 1, 2024

Implemented by

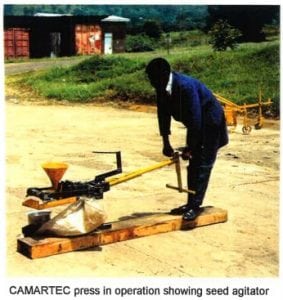

Centre for Agricultural Mechanization and Rural Technology (CAMARTEC)

Agriculture

August 29, 2024

Implemented by

Alvan Blanch

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Agriculture

September 10, 2024

Implemented by

Tinytech Plants

Agriculture

December 22, 2023

Implemented by

Engineers Without Borders USA

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

June 23, 2024

Implemented by

MAPS (Mobile Agricultural Power Solutions)

Agriculture

June 19, 2024

Implemented by

Inmarsat

Have thoughts on how we can improve?

Give Us Feedback