Agriculture

January 3, 2024

Life Sack

Read SolutionImplemented by

Jung Uk Park, Myeong Hoon Lee, and Dae Youl Lee

Updated on January 8, 2024

·Created on June 10, 2016

The DayOne Waterbag is an all-in-one water transport and purification backpack that uses P&G Purifier of Water packets for water treatment.

DayOne Waterbag is a personal water treatment backpack with a built-in filter and an initial supply of 60 Proctor and Gamble (P&G) Purifier of water flocculant-disinfectant packets. It is for water collection, transport, treatment, and protected storage.

This product is discontinued and no longer available.

Target SDGs

SDG 6: Clean Water and Sanitation

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$79.99

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

This product has been implemented by organizations such as AmeriCares, care, ChildFund, World Vision, Giving Children Hope, ADRA, and International Medical Corps.

Regions

Worldwide

Manufacturing/Building Method

Unknown

Intellectural Property Type

Patent

User Provision Model

This product is available for purchase as individual units and bulk orders from the DayOne website. In addition, a person or organization can "sponsor" Waterbags to be distributed. DayOne Response works with a variety of organizations that implement Waterbags in areas of disaster.

Distributions to Date Status

The exact number of distributions to date is unknown, however, the DayOne Waterbag has been deployed in over 20 countries, including the Philippines, Nepal, Thailand, Cambodia, Benin, Ghana, the Ivory Coast, Zimbabwe, Uganda, Venezuela, Nicaragua, and Haiti, among others.

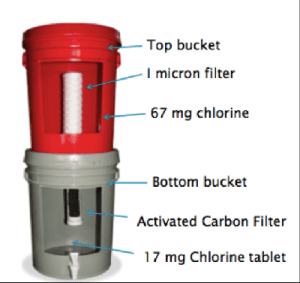

Description of the combined methods

Flocculation, Disinfection, Filtration

Manufacturer-specified water treatment rate (L/hr)

20 L/hr

Bacteria reduction

6 log

Virus reduction

4 log

Protozoa reduction

3 log

Heavy metals and/or arsenic reduction

Yes, reduction rate unknown

Maximum recommended influent turbidity level (NTU)

Unknown

Effluent turbidity levels (NTU)

0.25 – 3.2 NTU

Safe water storage capacity (L)

10 L

Manufacturer-specified lifetime volume (L)

600 L

Consumables

P&G treatment packets

Design Specifications

The Waterbag is made from durable Food Grade plastic that stores up to 10 L of water. The water is collected in the Waterbag and a PUR packet is added to the bag and is closed. The bag is then hung (from a branch or other device) and mixed for 5 minutes. The bag should be left hanging for 25 minutes, allowing all particles to settle at the bottom. Water can then be dispensed with the nozzle on the bag.

An instructional video is available on the DayOne website.

Technical Support

Technical support is provided by DayOne Response.

Replacement Components

The Waterbag include 60 P&G packets with each purchase. Replacement P&G packets are 19.99 USD for an additional 12 or 99.99 USD for an additional 240. One packet is used for each 10 L of water.

Lifecycle

The Waterbag can be stored at room temperature for 10 years from date of manufacture. P&G packets can be stored for 3 years from date of manufacture.

Manufacturer Specified Performance Parameters

The product was designed for the removal of turbidity, cysts (>3 logs), viruses (>4 logs), bacteria (>6 logs) and arsenic from contaminated water sources such as creeks, rivers, lakes, and ponds.

Vetted Performance Status

The US Environmental Protection Agency (US EPA) demonstrated that P>M Purifier of Water removed >99.9999% of pathogenic bacteria, >99.99% of viruses, and >99.9% of parasites including Giardia and Cryptosporidium. The P>M Purifier of Water packets have been tested by Centers for Disease Control and Prevention (CDC), US EPA, and University of Michigan.

Safety

The P>M Purifier of Water powder is hazardous if ingested. If swallowed, contact poison control center and sip on a glass of water for 15 – 20 minutes. If in eye, rinse eyes thoroughly with water for 15-20 minutes. If on skin, remove contaminated clothing and rinse skin with water for 15 – 20 minutes.

The product is not appropriate for soapy water, sea or saltwater, blackwater, or water contaminated with gasoline.

Complementary Technical Systems

The P>M Purifier of Water is essential to the function of the Waterbag.

Academic Research and References

Lougheed, T., 2006, “A Clear Solution for Dirty Water,” Environmental Health Perspectives, 114, pp. 424-427.

Blanton, E., et al., 2010, “Evaluation of the Role of School Children in the Promotion of Point-of-Use Water Treatment and Handwashing in Schools and Households-Nyanza Province, Western Kenya,” The American Journal of Tropical Medicine and Hygiene, 82, pp. 664-671.

Doocy, S., Burnham, G., 2006, “Point-of-use water treatment and diarrhoea reduction in the emergency context: an effectiveness trial in Liberia,” Tropical Medicine and International Health, 11, pp. 1542-1552.

Allgood, G., 2009, “Safe drinking water for the most vulnerable,” International Nursing Review, 56, pp. 273-275.

Souter, P.F., et al., 2003, “Evaluation of a new water treatment for point-of-use household applications to remove microorganisms and arsenic from drinking water,” Journal of Water and Health, 1, pp. 73–84.

Crump, J., et al., 2005, “Household based treatment of drinking water with flocculant-disinfectant for preventing diarrhoea in areas with turbid source water in rural western Kenya: cluster randomised controlled trial,” BMJ 2005;331:478.

Reller, M.E., et al., 2003, “A randomized controlled trial of household-based flocculant-disinfectant drinking water treatment for diarrhea prevention in rural Guatemala,” The American Journal of Tropical Medicine and Hygiene, 69, pp. 411-419

Compliance with regulations

The product is compliant with the US EPA standards for safe drinking water.

Evaluation methods

The product was evaluated through laboratory water tests by the US EPA. In the HIF Emergency Household Water Filter Challenge, filters were tested for ease-of-use, effectiveness, lifespan, robustness, and affordability and evaluated in a matrix for different disaster scenarios.

Other Information

The product is not appropriate for soapy water, sea or saltwater, blackwater, or water contaminated with gasoline.

Agriculture

January 3, 2024

Implemented by

Jung Uk Park, Myeong Hoon Lee, and Dae Youl Lee

Agriculture

June 22, 2024

Implemented by

Wello

Agriculture

January 3, 2024

Implemented by

Suprio Das

Agriculture

January 2, 2024

Implemented by

Archimedes Project

Agriculture

January 3, 2024

Implemented by

Helioz

Agriculture

December 28, 2023

Agriculture

January 24, 2024

Implemented by

Gift of Water

Agriculture

January 18, 2024

Implemented by

Agua Clara LLC

Agriculture

January 26, 2024

Implemented by

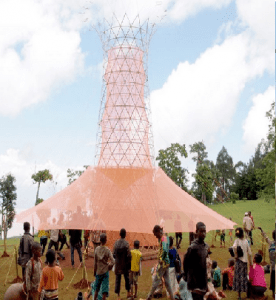

Warka Water

Agriculture

January 27, 2024

Implemented by

Medentech Ltd

Have thoughts on how we can improve?

Give Us Feedback

As per Bob: Manufacturing

of this type of product requires documented process and assembly

standards. In volumes of 100 special

attention needs to be paid to ensure that each unit is not a unique “one ofâ€

but rather follows and industrialized, documented and controlled assembly and

test process. With the exception of the

setup and assembly/test of the actual UV unit no special manufacturing

processing is required.

Trained users imply that training processes and support materials will be made available. Ongoing application and service support will be required. Trainers will be required to develop user guides and training classes.

This product states that repair parts will not be available and that support will not be provided to the customer by the manufacturer. This is not practical for an installed base of more than ~50 units. The global distribution to both Africa and India will require 24 x 7 staffing and when repair is required the unit will either need to be returned for repair or repaired on site by someone sent out from the factory. Neither approach is practical.