Agriculture

January 3, 2024

Life Sack

Read SolutionImplemented by

Jung Uk Park, Myeong Hoon Lee, and Dae Youl Lee

Updated on January 8, 2024

·Created on August 27, 2015

A community-scale gravity-fed water treatment unit.

GravityPure UF is a gravity-driven water treatment system, sized for community or facility use and scalable from 500 to 10,000 liters per day. Interview with representative

Target SDGs

SDG 6: Clean Water and Sanitation

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$6,700.00

Target Users (Target Impact Group)

Community

Distributors / Implementing Organizations

Distributed by Healing Waters. Implemented by Healing Waters, Warzone Solutions, Food for the Hungry, World Orphan Fund, Compassion Uganda, Sustainable Missions and many others.

Manufacturing/Building Method

Batch assembled, up to 6 week lead time for large orders. Interview with the representative

Intellectural Property Type

Trade Secret

User Provision Model

The GravityPure UF is purchased from Healing Waters (infoathealingwatersdotorg) by non-profits, NGOs, and other organizations or facilities around the world with a need for water treatment. The Healing Waters Engineering Team will work with you directly to size your equipment and make sure it’s a good fit for your context.Interview with representative

Shipping: 3 boxes or duffel bags, gross 54kg (for a 1-membrane unit)

Distributions to Date Status

Healing Waters has implemented over 200 water projects around the world. This particular design is newer, with 38 units produced to date.Interview with representative

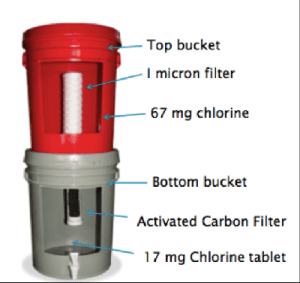

Description of the combined methods

Ultrafiltration membrane

Manufacturer-specified water treatment rate (L/hr)

40 to 550 L/hr (for 1 to 4 membranes)

Bacteria reduction

>4 log

Virus reduction

>4 log

Protozoa reduction

>4 log

Heavy metals and/or arsenic reduction

Unknown

Maximum recommended influent turbidity level (NTU)

Unknown

Effluent turbidity levels (NTU)

<0.1 NTU

Safe water storage capacity (L)

55 L

Manufacturer-specified lifetime volume (L)

Unknown

Consumables

Unknown

Design Specifications

GravityPure UF Dimensions:

Assembled: 101 cm x 77 cm x 149 cm, 51 kg

Typical assembly time: 2 hours

Overview: Interview with representative

Core treatment is ultrafiltration: 0.02-micon pores for removal of bacteria, viruses, and other waterborne diseases

Process is low-waste, with typically >90% net water recovery

Integrated bottle washing station for sanitizing inside of bottles

Water Supply:

Any fresh water supply (not salt water)

Must be tested for chemical contamination

Should be stored in an elevated holding tank.

Power Supply: Must pump or manually feed water to at least 2 meters.

Technical Support

Healing Waters Engineering Team. Interview with representative

Replacement Components

Extensive package of spare parts is included with each unit. Additional parts are available from Healing Waters, although many are locally available in urban areas. Interview with representative

Lifecycle

The manufacturer provides a 1 year warrenty. Disposal is a mixture of non-hazardous waste and recyclable components (eg stainless steel frame). The most significant replacement cost is the Ultrafiltration Membrane. Typical membrane life is 2-5 years, with a $300 replacement cost. Interview with representative

Manufacturer Specified Performance Parameters

GravityPure UF can achieve a production rate from 500 to 10,000 liters per day depending on water pressure and number of parallel Ultrafiltration membranes.

Vetted Performance Status

Unknown

Safety

No hazards noted.

Complementary Technical Systems

In some cases there may be a need for large water storage tank(s), sand pre-filtration, or activated carbon post-filtration. The Healing Waters Engineering Team will work with the users to make sure that they have the right solution for their context. Interview with representative

Academic Research and References

Healingwaters.org. Available: https://healingwaters.org/wp-content/uploads/2020/03/GravityPure_SpecSheet.pdf

“Clean Water Initiative,” Healing Waters International, 15-Nov-2023. Available: https://healingwaters.org/

“Home Page,” Food for the Hungry, 20-Apr-2023. Available: https://www.fh.org/

“The,” World Orphan Fund, 28-Feb-2022. Available: https://www.theworldorphanfund.org/

“Uganda,” Compassion.com. Available: https://www.compassion.com/about/where/uganda-facts.htm

Goal 6. (n.d.). Sdgs.un.org. Available: https://sdgs.un.org/goals/goal6

Compliance with regulations

The Ultrafiltration membrane is produced in an ISO 9001 certified facility and is NSF 61 listed. Interview with representative

Evaluation methods

Field and laboratory testing

Other Information

None.

Agriculture

January 3, 2024

Implemented by

Jung Uk Park, Myeong Hoon Lee, and Dae Youl Lee

Agriculture

June 22, 2024

Implemented by

Wello

Agriculture

January 3, 2024

Implemented by

Suprio Das

Agriculture

January 2, 2024

Implemented by

Archimedes Project

Agriculture

January 3, 2024

Implemented by

Helioz

Agriculture

December 28, 2023

Agriculture

January 24, 2024

Implemented by

Gift of Water

Agriculture

January 18, 2024

Implemented by

Agua Clara LLC

Agriculture

January 26, 2024

Implemented by

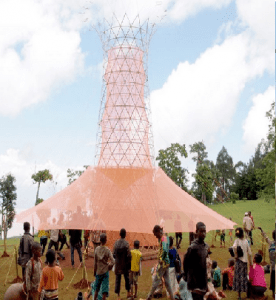

Warka Water

Agriculture

January 27, 2024

Implemented by

Medentech Ltd

Have thoughts on how we can improve?

Give Us Feedback