Agriculture

February 6, 2024

SAYeTECH Multi-Crop Thresher

Read SolutionImplemented by

SAYeTECH Ltd

Updated on February 6, 2024

·Created on September 22, 2016

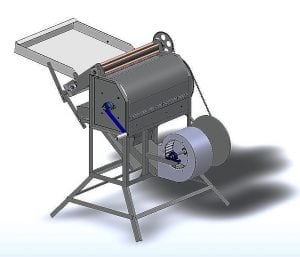

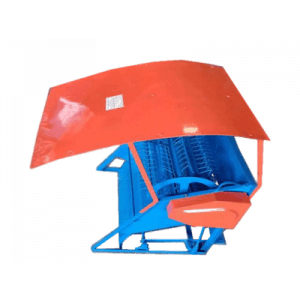

Imara Tech Multi-Crop Thresher is a product used to thresh crops such as rice, maize, wheat, sorghum and barley more quickly than traditional methods.

The Multi-crop thresher (MCT) is a machine that can thresh crops such as rice, maize, wheat, sorghum, barley. The MCT is an improvement on traditional methods which eliminates the need for the toilsome labor and significantly reduces the time required to thresh from three hours to ten minutes per sack of rice. The MCT is designed and implemented by Imara Tech.

Target SDGs

SDG 2: Zero Hunger

SDG 8: Decent Work and Economic Growth

Market Suggested Retail Price

$700.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Imara Tech

Competitive Landscape

Direct competitors include Pearl Millet Thresher.

Regions

East Africa

Countries

Tanzania

Manufacturing/Building Method

The Multi-Crop Thresher is manufactured in Tanzania. It is built using sheet metal, mild steel, nuts/bolts and welding rods and fabricated manually with a welding machine, hand tools, drill press and lathe.

Intellectural Property Type

Patent

User Provision Model

Imara Tech aims to make business-to-business sales to partner organizations specializing in the distribution and sales in rural areas. The product is also aimed at entrepreneurs as an additional source of income. Users will be able to purchase MCTs at the fabrication workshops which also act as service centers for machine repairs, showrooms, office space and storage areas. The company intends to provide loans for purchasing the machine.

Distributions to Date Status

2750 units

Feedstock type

Maize, sorghum, barley, and rice

Feedstock rate (kg/hr)

2500 kg/hr

Manual or motorized

Motorized

Energy requirement (W)

4847 W

Portable or stationary

Portable

Design Specifications

The Multi-Crop Thresher (MCT) is a throw-in type thresher. This means that crops are fed into the machine from the top. Once they enter the threshing chamber, a rotating drum beats the grains off of the stalks. Large chaff passes through to the exit of the chamber and expelled from the machine, while threshed grain falls through a sieve-like structure called a concave. A fan blows dust and small chaff from the threshed grain, which then leaves the machine through an exit chute to be collected in bags. The thresher is powered by a small 6.5 HP petrol engine. The MCT is made using sheet metal, mild steel, nuts/bolts, welding rods and PPE.

The MCT is designed for portability in the field and around rural settings, it is equipped with two wheels. It also has an indented seat so that it easily fits onto the back of a motorcycle rack.

Technical Support

It is foreseen that the most common modes of failure can be repaired by local technicians. However, Imara Tech plans to use the MCT fabrication workshops as service centers for machine repairs.

Replacement Components

Sheet metal, mild steel, nuts/bolts

Lifecycle

5-10 years

Manufacturer Specified Performance Parameters

The Multi-Crop Thresher is designed to thresh crops in a relatively short time compared to traditional threshing methods. It can process 1000 kgs of maize in 24 minutes

Vetted Performance Status

Testing by the manufacturer found the MCT to be up to 90 times faster than traditional methods of threshing.

Safety

The potential risks associated with this product include grain projectiles from the thresher and minor winding risk.

Complementary Technical Systems

Entrepreneurs in villages can buy the machine and provide service to smallholder farmers, earning the operator up to 10 USD per hour.

Academic Research and References

Nwakaire, J. N., Ugwuishiwu, B. O., and Ohagwu, C. J., 2011, Design, Construction, and Performance Analysis of a Maize Thresher for Rural Dweller. Nigerian journal of technology, Vol. 30.

Compliance with regulations

None

Other Information

Agriculture

February 6, 2024

Implemented by

SAYeTECH Ltd

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Agriculture

February 24, 2024

Implemented by

Compatible Technology International

Agriculture

February 6, 2024

Implemented by

Compatible Technology International

Agriculture

February 2, 2024

Implemented by

Agro Vision

Agriculture

September 19, 2024

Implemented by

Amaragri

Agriculture

December 30, 2023

Implemented by

EcoZoom

Agriculture

January 14, 2024

Implemented by

Niwa

Agriculture

January 14, 2024

Implemented by

Niwa

Agriculture

January 17, 2024

Implemented by

Technorbital

Have thoughts on how we can improve?

Give Us Feedback