Update: Please see below for a link to the research paper at Solutions Journal.

A steel wedge grate placed in a traditional Indian cook fire can increase the fuel efficiency and cut soot emissions by more than half, new research has found. The grate, called the Mewar Angithis, costs about US$1 to make, it doesn’t require cooks to learn to use anything new or change their cooking habits, and it beat much more expensive high-efficiency cookstoves in real-world comparisons.

“The Mewar Angithi outperformed both the High Efficiency Cookstoves by a wide margin,” Sailesh Rao of Climate Healers in Phoenix, Arizona, who was involved in the development of the grates, told E4C.

Standardized laboratory tests confirmed the device’s benefits, according to data that will be published in the August edtion of the Solutions Journal by Rao and his team from the University of Iowa in Iowa City, USA, and Maharana Pratap University in Udaipur, Rajasthan, India.

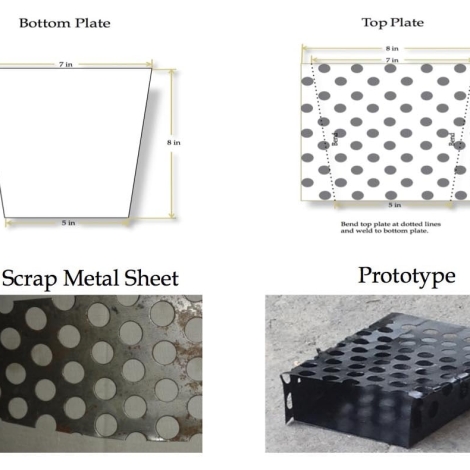

The Mewar Angithi stove grate. Photo courtesy of Sailesh Rao

A government-approved cookstove testing center at Maharana Pratap University ran the grate through six rounds of tests. The lab boiled water over a traditional three-stone cooking fire with and without the grate. The grated fires burned 63 percent less wood and produced 88 percent less soot, the lab reports.

“Our Indian representative, Vasanth Kukillaya, was there [during the lab test]. He told me that it took them a whole day to run the tests with and without the Angithi. Further, they repeated the test the next day as well, since they were surprised by the results,” Rao says.

Real-world performance matters

But to Rao, the most meaningful experiments were those done in the kitchens of the women who cook every day over chulhas, the traditional cooking fires. The researchers compared cook fires with grates to two brands of high-efficiency improved cookstoves and cookfires without grates.

Rao and his team looked on as women cooked meals in three homes in the Mewar region of Rajasthan. To even out the differences between the sizes of the meals cooked over each fire and stove, the researchers calculated the weight of wood required to cook one corn roti.

The average weight of wood needed to cook a roti over a traditional chulha without the insert was 0.161kg. The wood needed for each of the two improved cookstoves was 0.122kg and 0.126kg. But the grated chulha only required 0.066kg.

“As far as the women are concerned, it is this real-world performance that matters,” Rao says.

Lab tests measured the cookfires’ thermal efficiency, the ratio of thermal energy delivered to the pot versus the amount of thermal energy locked into the wood. They also calculated the power rating, the rate at which the fire delivers thermal energy to the pot (expressed in kilowatts). They found that the grated chulhas have an average 24.5 percent efficiency and 1.346KW power rating, more than double that of the chulha without the grate.

Compared to grateless fires, emissions from the grated fires contained less than half of the carbon monoxide, at 5.97 grams (of CO) per megajoule of thermal energy delivered to the pot.And the grates emitted about one-tenth of the total particulate matter. We’ve reproduced a table from the study that shows the lab results.

Opinions vary on the best ways to test improved cookstoves, so we ran these findings by a cookstove testing expert, Crispin Pemberton-Pigott, a technical consultant to the World Bank for stove programs.

“If the goal is to reduce fuel consumed per replication of a task, in any of a series of replications, then the new raw fuel mass needed per replication is a very good way of determining the consumption of the resource,” Pemberton-Pigott says. He was not surprised by the results, he says, although the fuel savings of 63 percent did seem high.

Made cheaply from scrap

Steel washer manufacturers leave behind metal sheets punched through with washer-sized holes, and they happen to be perfect for creating Mewar Angithi inserts. Rao and his team found that they could make an insert for about US$1 each using perforated scrap sheets from a washer manufacturer in Udaipur.

Inserts are not new

Inserts like this one are not new to cooking and some may have been tested at least as rigorously as this one, according to experts that E4C has consulted. Pemberton-Pigott works to set stove standards in Indonesia and he has seen another grate used there.

“The significant difference between the two devices is that the Chulha version has the air entering from the front and the Improved Keren Stove version has the air entering from the back. The rear entrance reduces the amount of charcoal wasted and keeps the flames more to the center, away from the back wall which is a significant source of PM and CO (touching a wall, that is),” Pemberton-Pigott says.

Design notes

The insert could perform better if it covered a larger percentage of the area of the floor of the chulha, Pemberton-Pigott says. Another performance enhancement may be to put a hole into the chulha itself to allow the insert to pull outside air through the rear of the stove. He suggests a hole that is 50mm wide and 20mm high, aimed directly into the grate.

Also, the grate does not allow for the removal of ash during the burn, which might be a problem, depending on the users’ cooking habits. Although Rao and his team have intentionally designed the holes in the grate to prevent embers from falling through during the burn, Rao says.

To improve the stove’s efficiency, chulha builders might consider lowering the pot-holder walls.

“If the pot rests are reduced in height to create a control over the amount of air rushing pointlessly through the stove – typically 7-8mm high is adequate. Definitely not 20mm,” Pemberton-Pigott says.

See the paper

Please see Rao et al’s paper, A Simple, Inexpensive Device Makes a Three-Stone Hearth as Efficient as an Improved Cookstove, published in Solutions Journal.

Comments from the Community

1 Comment