Agriculture

January 12, 2024

Updated on August 15, 2024

·Created on October 2, 2018

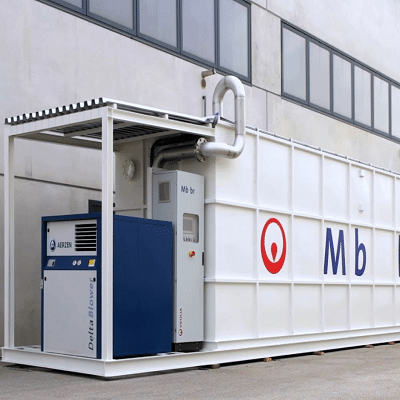

The AnoxKaldnes Moving Bed Biofilm Reactor (MBBR) is a wastewater treatment technology that consists of an aeration tank containing plastic media, on which biofilm can grow.

The AnoxKaldnes Moving Bed Biofilm Reactor (MBBR) is a wastewater treatment technology that uses biofilm carriers to optimize bacteria cultures for use in industrial and municipal applications. The plastic carriers are mixed with the wastewater by an aeration system, and the treated water flows out of the tank through a sieve. The compact system removes BOD, ammonia, and nitrogen, and the design of systems in flexible based on application.

The AnoxKaldnes MBBR is built and priced to bespoke configurations based on-site requirements.

Target SDGs

SDG 6: Clean Water and Sanitation

Target Users (Target Impact Group)

Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

Veolia Water Technologies UK

Competitive Landscape

Direct competitors include Sequential Batch Reactor, Membrane Biofilm Reactor, and Decentralized Wastewater Treatment Systems (DEWATS).

Regions

Worldwide

Manufacturing/Building Method

The AnoxKaldnes MBBR is built to bespoke configurations and customised to meet the sites specific requirements.

Intellectural Property Type

Patent

User Provision Model

MBBRs are designed with and then purchased though the manufacturer, to ensure that treatment is optimal for specific applications.

Distributions to Date Status

More than 600 MBBR systems have been implemented worldwide.

Flow rate (L/min)

100 – 800 L/min

Power Supply Type

Electrical

Technology type

MBBR, aeration, biofilm

BOD Removal Efficiency

96%

COD removal efficiency

99%

NH4-N Removal Efficiency

99%

TSS removal efficiency

85%

Total Phosphorus Removal Efficiency

68%

Fecal Coliform Removal Efficiency

100%

Design Specifications

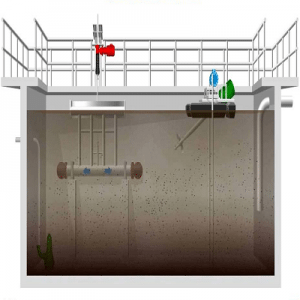

The AnoxKaldnes MBBR system is designed as a tank with an inlet for wastewater and an outlet, covered by a sieve, for the treated wastewater. Small plastic biofilm carriers are mixed in the tank through aeration from the bottom of the tank. These carriers are designed to provide the optimal surface area for biofilm to grow on, effectively treating the wastewater.

Technical Support

Technical support is provided by the manufacturer through various water services and maintenance support packages. These packages include water plant maintenance and chemicals for water treatment. In addition all of the packages include remote technical support.

Replacement Components

Individual components are available from the manufacturer for replacement through the technical support plans.

Lifecycle

The AnoxKaldnes MBBR has has an observed operational lifespan of over 15 years with no reduction in performance.

Manufacturer Specified Performance Parameters

The manufacturer specifies performance targets related to small plant footprints, accommodating high loading, and creating optimal bacteria culture conditions.

Vetted Performance Status

The product has been tested by a range of academic institutions including Lund University, Aarhus University, The University of Auckland, and the University of Ottawa related to design, functionality, and impact of temperature.

Safety

The AnoxKaldnes MBBR must be operated safely and correctly to ensure that users are not harmed by either the growing bacteria or the untreated wastewater.

Complementary Technical Systems

The system can be coupled with settlers, clarifiers, or disk filters which enable downstream separation of sludge from treated water.

Academic Research and References

McQuarrie, J., Boltz, J., 2011, Moving Bed Biofilm Reactor Technology: Process Applications, Design, and Performance, Water Environment Research 83: 560-75.

Hoang, V. et. al., 2014, Nitrifying moving bed biofilm reactor (MBBR) biofilm and biomass response to long term exposure to 1C, Water Research 49: 215-224.

Biswas, K., Taylor, M., Turner, S., 2013, Successional development of biofilms in moving bed biofilm reactor (MBBR) systems treating municipal wastewater, Applied Microbiology and Biotechnology 98: 1429-1440.

Casas, M. et. al., 2015, Biodegradation of pharmaceuticals in hospital wastewater by staged Moving Bed Biofilm Reactors (MBBR), Water Research 83: 293-302.

Hoang, V., et al., 2014, An Investigation of Moving Bed Biofilm Reactor Nitrification during Long-Term Exposure to Cold Temperatures, Water Environment Research, 86: 36-42.

Biswas, K., Taylor, M. W., Turner, S. J., 2014, Successional development of biofilms in moving bed biofilm reactor (MBBR) systems treating municipal wastewater, Environmental Biotechnology 98: 1429-1440

Shokoohi, R. et al., 2017, Study of the efficiency of moving bed biofilm reactor (MBBR) in LAS Anionic Detergent removal from hospital wastewater: determination of removing model according to response surface methodology (RSM), Water Sci. Technology 2017(1): 1-7

Sidek, L. M., 2015, Experimental Comparison between Moving Bed Biofilm Reactor (MBBR) and Conventional Activated Sludge (CAS) for River Purification Treatment Plant, Advanced Materials Research 1113: 806-811

Hadei, M. et al., 2015, A survey on the performance of moving bed biofilm reactor and rapid sand filter in wastewater treatment, Journal of Advances in Environmental Health Research 3(3)

Piculell, M., 2016, New dimensions of moving bed biofilm carriers influence of biofilm thickness and control possibilities, Ph.D dissertation, Lund University, Lund, Sweden.

Zafarzadeh, A. et al., 2010, Performance of Moving Bed Biofilm Reactors for Biological Nitrogen Compounds Removal from Wastewater by Partial Nitrification-Denitrification Process, Iran. J. Environ. Health. Sci. Eng., 7 (4): 353-364

Compliance with regulations

Veolia Water Technologies builds systems tailored to meet site objectives and to comply with regulations for applications such as water reuse, wastewater treatment and sewage treatment.

Evaluation methods

Each MBBR system is monitored and evaluated remotely during operation to ensure optimal system performance and to manage required maintenance.

Other Information

MBBR systems can be used in a variety of applications from wasterwater management to environmental protection. Here are the case studies related to two treatment projects:

Aquacria-Piscicolas Turbot Fish Farm

Patent Protected

This video further explains how the system works.

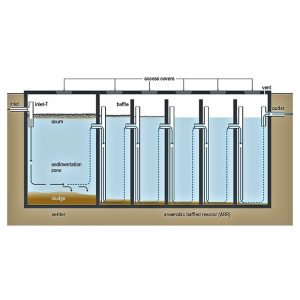

AnoxKaldnes MBBR Schematics

Agriculture

January 12, 2024

Agriculture

August 15, 2024

Implemented by

EAWAG

Agriculture

January 11, 2024

Agriculture

August 16, 2024

Agriculture

August 8, 2024

Implemented by

Patrick Kiruki, Banza Sanitation

Agriculture

January 10, 2024

Implemented by

Dr. David Manz, University of Calgary

Agriculture

August 13, 2024

Implemented by

The Africa Trust

Agriculture

August 14, 2024

Implemented by

Envirosan

Agriculture

August 14, 2024

Implemented by

WaterSHED

Agriculture

December 26, 2023

Implemented by

Mechanical Engineering Research & Development Organization (MERADO)

Have thoughts on how we can improve?

Give Us Feedback