Agriculture

August 15, 2024

AnoxKaldnes Moving Bed Biofilm Reactor

Read SolutionImplemented by

AnoxKaldnes

Updated on January 12, 2024

·Created on September 30, 2018

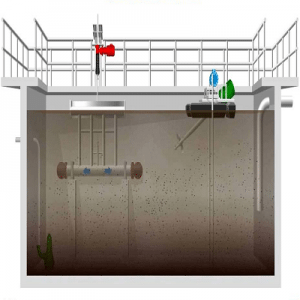

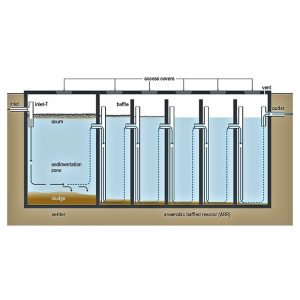

Membrane Biofilm Reactors (MBR) are wastewater treatment systems which combine the membrane process of microfiltration with biological activated sludge process.

Membrane Biofilm Reactors (MBR) are wastewater treatment systems that combine a semi-permeable membrane with biological treatment processes. The membrane enables microfiltration while a suspended growth bioreactor enables biological decomposition. This type of wastewater treatment is commonly used by municipalities and industrial treatment.

The costs of MBR are dependant on the size of the system.

Target SDGs

SDG 6: Clean Water and Sanitation

Target Users (Target Impact Group)

Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

The MBR has been implemented by Weise Water GmbH, Fluence, Martin Membrane Systems, Triqua International bv and Ovivo.

Competitive Landscape

Direct competitors include AnoxKaldnes Moving Bed Biofilm Reactor and Sequential Batch Reactor.

Regions

Worldwide

Manufacturing/Building Method

MBRs are constructed by the manufacturer. For larger wastewater treatment plants, MBRs are build to bespoke specifications based on site specifications.

Intellectural Property Type

Open-source

User Provision Model

Users can obtain MBR directly from local manufacturers.

Distributions to Date Status

Due to the open source nature of the product, an exact distribution to date is unknown.

Flow rate (L/min)

Flow rate dependant on site specifications. <27.77 L/min for small containerised plants and 1527-13,194 L/min for municipal plants.

Power Supply Type

Electrical

Technology type

Membrane, microfiltration, biological activated sludge process

BOD Removal Efficiency

98-99%

COD removal efficiency

99%

NH4-N Removal Efficiency

99%

TSS removal efficiency

99.9%

Total Phosphorus Removal Efficiency

97%

Fecal Coliform Removal Efficiency

90%

Design Specifications

The membranes in MBR are designed to have pores between 0.035 - 0.4 microns, depending on the desired level of filtration. The membrane type (including hollow fiber, spiral-wound, plat-and-frame, pleated filter cartridge, and tubular) is chosen by designers for application-specific designs. This scale of membranes eliminates the need for sedimentation, allowing the biological processes to operate at higher concentrations.

Technical Support

The complexity of the MBR system design requires that operators are technically trained. Training can be provided by the manufacturers.

Replacement Components

Replacement components are available directly from manufacturers.

Lifecycle

10 years

Manufacturer Specified Performance Parameters

Manufacturers specify performance targets related to eliminating the need for secondary filtration, reducing the plant footprint, prolonging sludge age (and therefore lowering sludge production), producing high quality effluent, and allowing for high loading rates.

Vetted Performance Status

Testing by the Lulea University of Technology to determine MBRs are viable for onsite wastewater treatment systems due to MBRs efficient COD (90 %) and Nitrogen (99 %) removal. Additional treatment is required for phosphorus removal to meet water quality regulations.

Safety

To reduce health risks, sludge should be dried and incinerated. The ashes can be stored in a landfill to prevent human contact.

Complementary Technical Systems

Cleaning systems must be used to maintain the membranes in MBR. Often the cleaning is performed using chemical mixtures to defoul the membranes.

Academic Research and References

Ueda, T., et al., 1997, “Effects of aeration on suction pressure in a submerged membrane bioreactor”, Water Research, 31: 489-494.

Larsson, E. and Persson, J., 2004, “Viability of Membrane Bioreactor Technology as an Advanced Pre-treatment for Onsite Wastewater Treatment“, Masters dissertation, Luleå University of Technology, Luleå, Sweden

Clara, M. et. al., 2005, “Removal of selected pharmaceuticals, fragrances and endocrine disrupting compounds in a membrane bioreactor and conventional wastewater treatment plants“, Water Research 39: 4797-4807.

Judd, S., 2008, “The status of membrane bioreactor technology“, Trends in Biotechnology 26: 109-116.

Achill, A., et al., 2009, “The forward osmosis membrane bioreactor: A low fouling alternative to MBR process”, Desalination 239: 10-21.

Aybar, M. et al., 2012, The Air-based Membrane Biofilm Reactor (MBfR) For Energy Efficient Wastewater Treatment, Proceedings of the Water Environment Federation 2012(10): 5458-5485

Kraume, M. et al., 2005, Nutrients removal in MBRs for municipal wastewater treatment, Water Sci. Technol. 51(6-7): 391-402

Lo, C.H., McAdam, E., Judd, S., 2015, The cost of a small membrane bioreactor, Water Science and Technology 72(10): 1739-1746

Compliance with regulations

The use of MBRs can aid wastewater treatment sites comply with country water quality discharge standards.

Evaluation methods

Each MBR is visually evaluated weekly to determine the extent to which fouling has clogged the membrane; when filtration has decreased, the membrane must be cleaned before operation continues.

Other Information

SSWM Factsheet - Membrane Bioreactor

Agriculture

August 15, 2024

Implemented by

AnoxKaldnes

Agriculture

August 8, 2024

Implemented by

Cranfield University

Agriculture

August 15, 2024

Implemented by

EAWAG

Agriculture

January 11, 2024

Agriculture

August 16, 2024

Agriculture

January 11, 2024

Implemented by

Caminos de Agua

Agriculture

January 17, 2024

Implemented by

Aquagenx

Agriculture

September 23, 2023

Implemented by

Innovations for Poverty Action

Agriculture

January 2, 2024

Implemented by

Deep Springs International

Agriculture

August 4, 2024

Have thoughts on how we can improve?

Give Us Feedback