Agriculture

December 11, 2024

A-Light S

Read SolutionImplemented by

Ambros Huber

Updated on December 17, 2024

·Created on October 5, 2018

Distributed by ATEC, this biodigester converts green waste into biogas for cooking and organic fertilizer for crops and comes along with a twin cookstove and biogas rice cooker.

ATEC biodigester converts animal, organic, and kitchen waste into approximately 500 to 1500 L of biogas per day. The gas can be used for cooking and the organic byproduct is suitable to produce 20 tons of organic fertilizer per year for crops. This product is the first commercialized biodigester also suitable for earthquake and flood-prone areas. The system comes with a twin cookstove and a biogas rice cooker, along with the biodigester itself. The system requires a minimum of 2 livestock or 5 kg of green waste per day and there are two sizes available: 3,25 m3 for small-scale farmers and 10 m3 for medium-scale farms.

ATEC Biodigesters International is a triple bottom line impact enterprise operating in Cambodia.

Target SDGs

SDG 7: Affordable and Clean Energy

SDG 8: Decent Work and Economic Growth

Market Suggested Retail Price

$650.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

ATEC in partnership with other organisations and companies for the technical, sales and supply chain needs.

Competitive Landscape

Direct competitors include Green Heat Biogas Digester, HomeBiogas, Flexigester V10, ADRA Cold Climate Biodigester, ARTI Biogas Plant, MBSA Biogas Plant, TINYTECH Portable Biogas Plant, and Rotoplast Biodigestor.

Countries

Australia, Burma, Cambodia, Indonesia, Papua New Guinea, Thailand

Manufacturing/Building Method

ATEC biodigesters use a rotor-moulded design, with export-quality UV-treated linear low density polyethylene (LLDP) plastic. Manufactured by H2O Co Ltd in Phnom Penh in Cambodia, there are two system's capacity available: 3,25 m3 (2 m high and 1,5 m wide) for small-scale farmers and 10 m3 for medium-scale farms.

Intellectural Property Type

Patent

User Provision Model

Users can obtain it directly by contacting the manufacturer and from its retail channels.

Distributions to Date Status

By 2020, 12 distributor channels are operating in Cambodia and 1,400 units have been installed during pilot phase with a 98% customer satisfaction. Along with Cambodia, further units have been installed in Myanmar (10 pilot units), Indonesia, PNG and Thailand.

Output energy product

Biogas

Average daily biogas production (m3/day)

0.5 m3/day- 1.5 m3/day

Description of waste source(s)

Manure, human, kitchen and green waste.

Waste input requirements (kg per hour or day)

A minimum of 20kg of cow/buffalo manure or 13kg of pig manure per day.

Description of other input requirements

N/A

Other input requirements (amount per hour)

N/A

System dimensions (m)

2 m height, 1.5 m wide. Total volume 3.25 m3.

Design Specifications

Design specifications include the twin cookstove, biogas rice cooker, and the biodigester with a new rotor-molded design that uses export-quality UV-treated LLDPE plastic. The biodigesters collect and treat manure, human, kitchen, and green organic waste to be converted to biogas that powers the twin cookstove. The biodigester can be directly plumbed to the household's toilet system.

Technical Support

The product comes with a user training and 5-step after-sales-service program. For further support, users must contact the manufacturer.

Replacement Components

Unknown

Lifecycle

The product has a 2-years warranty and an expected lifecycle of 25 years.

Manufacturer Specified Performance Parameters

The key benefits of having an ATEC biodigester are:

By having a biodigester an average Cambodian family will save an average family $521 per year.

ATEC's main goal is to expand the biodigester to 5 countries and disseminate 1 million systems by 2030 so as to create the impact of:

9.5 trillion liters of eco-friendly renewable biogas (51 million MWh equivalent)

24.6 billion hours saved from collecting and using wood

1/2 billion tons of organic fertilizer

12.4 billion USD net income increase in households

5.4 million tons of forest wood conserved

75 million tons of Greenhouse Gas reductions

Payback of 16 USD for every 1 USD spent on the unit

Vetted Performance Status

Tests performed by Engineers Without Borders Australia found an average reduction in E. Coli pathogen level of 2-log order, between input and output E-Coli levels, es expected for an anaerobic biodigester.

Safety

ATEC biodigester aims to reduce the potential health risks linked to the burning of traditional biomass and domestic accidents such as accidental burning or spill-overs in traditional open fires cookstoves. No known safety concerns can be associated with this product.

Complementary Technical Systems

The biodigester is complemented with the twin cookstove and the biogas rice cooker.

Academic Research and References

Buskauskas K., Koolhof K., Kim P., King M., 2017, Small-scale wastewater treatment technologies for challenging environments, Engineers Without Borders Australia and Engineers Without Borders New Zealand, Australia and New Zealand.

Case Study: ATEC* Biodigester. n.d. Engineers without Borders Australia.

ATEC* Smart Modern Farming. n.d. www.atecbio.com.

Compliance with regulations

Unknown

Evaluation methods

Unknown

Other Information

ATEC was the Google Impact Challenge Winner in 2016, global winner in the CTI PFAN in 2017, and the Australian Government Frontier Innovators Winner in 2018, along with other prizes that can be seen in the key milestones and recognition field.

Introduction video of the ATEC biodigester.

Agriculture

December 11, 2024

Implemented by

Ambros Huber

Agriculture

June 23, 2024

Implemented by

Bajaj

Agriculture

December 2, 2024

Implemented by

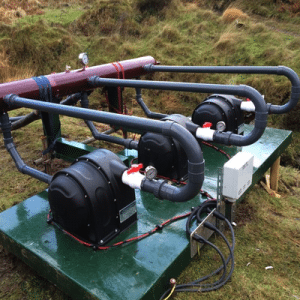

EcoInnovation Ltd. (Powerspout)

Agriculture

December 2, 2024

Implemented by

Mobile Hydro

Agriculture

January 22, 2024

Implemented by

Sistema.bio

Agriculture

December 10, 2024

Implemented by

Orb Energy

Agriculture

December 10, 2024

Implemented by

Orb Energy

Agriculture

December 18, 2024

Implemented by

Tinytech Plants

Agriculture

December 7, 2024

Implemented by

Shamba Technologies Ltd.

Agriculture

December 11, 2024

Implemented by

SolarNow

Have thoughts on how we can improve?

Give Us Feedback