Agriculture

August 29, 2024

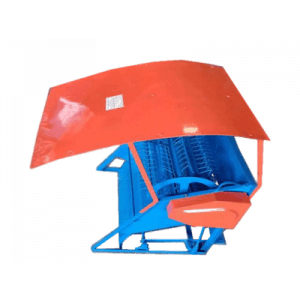

Alvan Blanch Groundnut Lifter/Inverter

Read SolutionImplemented by

Alvan Blanch

Updated on September 18, 2024

·Created on October 5, 2020

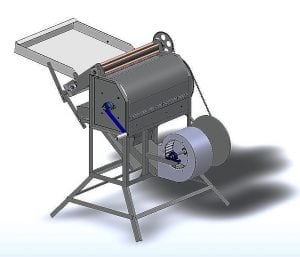

The Alvan Blanch Thresher is a portable thresher designed to process various grains.

The Alvan Blanch Midget Thresher is a portable thresher designed to process various grains and is adaptable for rice processing. The threshers contain grain collection boxes, plasticized canvass tarpaulin, and a tool kit for operation. The product was designed and is manufactured and distributed by Alvan Blanch.

Target SDGs

SDG 2: Zero Hunger

SDG 9: Industry, Innovation and Infrastructure

Market Suggested Retail Price

$2,152.32

Market Suggested Retail Price (Secondary Currency)

1815 EUR

Target Users (Target Impact Group)

Household, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

This product has been implemented through a network of approved dealers in over 100 countries.

Competitive Landscape

Direct competitors include SAYeTECH Multi-Crop Thresher, Pearl Millet Thresher, Imara Tech Multi-Crop Thresher, and Maya Pedal Bicycle Mill.

Regions

Africa, Asia, Caribbean, Europe, Middle East, North America

Countries

Russia, United Kingdom

Manufacturing/Building Method

This product is mass-produced in the United Kingdom.

Intellectural Property Type

Patent

User Provision Model

Users can obtain the product/service from Alvan Blanch's global list of approved dealers.

Distributions to Date Status

The exact number is unknown, but as of 2021, there have been Alvan Blanch projects completed in over 100 countries worldwide.

Feedstock type

Corn, rice

Feedstock rate (kg/hr)

500 kg/hr

Manual or motorized

Manual

Energy requirement (W)

2.25 kW

Portable or stationary

Portable

Design Specifications

The Alvan Blanch Midget Crop Thresher is a portable thresher designed with heavy gauge welded steel with lifetime sealed bearings and anti-corrosion paint, and a bolted tubular square support frame with feet. The product has dimensions: 1420 x 580 x 1900 mm with a total weight is 190 kg. The machine has a 317 mm Peg drum with an adjustable concave, a feed table, and a side discharge spout. The drive is a PTO shaft from Power Tiller, including an attachment for speed conversion to 540 rpm.Cleaning is done through manual rotation and raking.

The crop is fed directly into the drum from the table, and the separated grain falls through concave via the collection chute. The remaining grain, recovered as straw, is discharged from the drum onto fixed sloping sieve for secondary cleaning by manual raking.

Technical Support

Technical support is provided by the Alvan Blanch or its network of approved dealers.

Replacement Components

Unknown

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

Designer specified performance targets include maximum reliability, functionality, and operator safety.

Vetted Performance Status

Testing performed by scientists from the Indian Agricultural Research Institute (IARI) and Kansas State University found that the machine worked satisfactorily for paddy and sorghum threshing but was not suitable for millets, groundnut, and maize.

Safety

Potential hazards related to the operation of this product include sharp and fast cutting tools.

Complementary Technical Systems

The manufacturer also sells a mobile thresher model, the Alvan Blanch Aspra.

Academic Research and References

Singhal, O.P., Thierstein, G.E., 1987, “Development of an axial-flow thresher with multi-crop potential,” Agricultural Mechanization in Asia, Africa, and Latin America, 18(3), pp. 57-65.

Compliance with regulations

Unknown

Other Information

This video developed by Alvan Blanch illustrates the operation and features of a similar mobile thresher model, Aspra.

Agriculture

August 29, 2024

Implemented by

Alvan Blanch

Agriculture

September 10, 2024

Implemented by

Alvan Blanch

Agriculture

September 11, 2024

Implemented by

Alvan Blanch

Agriculture

February 6, 2024

Implemented by

SAYeTECH Ltd

Agriculture

February 6, 2024

Implemented by

MIT D-Lab

Agriculture

February 2, 2024

Implemented by

Agro Vision

Agriculture

September 19, 2024

Implemented by

Amaragri

Agriculture

February 24, 2024

Implemented by

Compatible Technology International

Agriculture

February 6, 2024

Implemented by

Compatible Technology International

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Have thoughts on how we can improve?

Give Us Feedback