Landscape Analysis of Post-Harvest Technologies for Mango Production in East Africa

Test about this

PARTNER COLLABORATORS: Dr. Kiruba Krishnaswamy, University of Missouri; Dr. Juan Andrade, University of Florida; Kate Dockins, Institute of Food Technologists

E4C EDITORIAL TEAM: Nishant Agarwal, E4C Expert Fellow; Mariela Machado, E4C Program Manager; Grace Burleson, E4C Research Manager

Click here to view the full report.

Mango cultivation is a major source of livelihood for many farmers in Kenya. Kenya produces 1,024,500 metric tonnes of mango annually but due to a number of factors, it is estimated that about half of the mangoes produced are lost. Among the contributors to the losses, poor postharvest handling techniques has been identified as a major contributor to mango postharvest losses in Kenya.

In order to help reduce these losses, this research sought to investigate the actors in the Kenyan mango value chain, identify the points in the value chain where the losses occur, highlight the current technologies that are being used for mango processing and propose new technologies that can be adopted for improved efficiency in the processing of mangoes to reduce postharvest losses. The research involved both desk research and semi-structured interviews of farmers, academics and other actors.

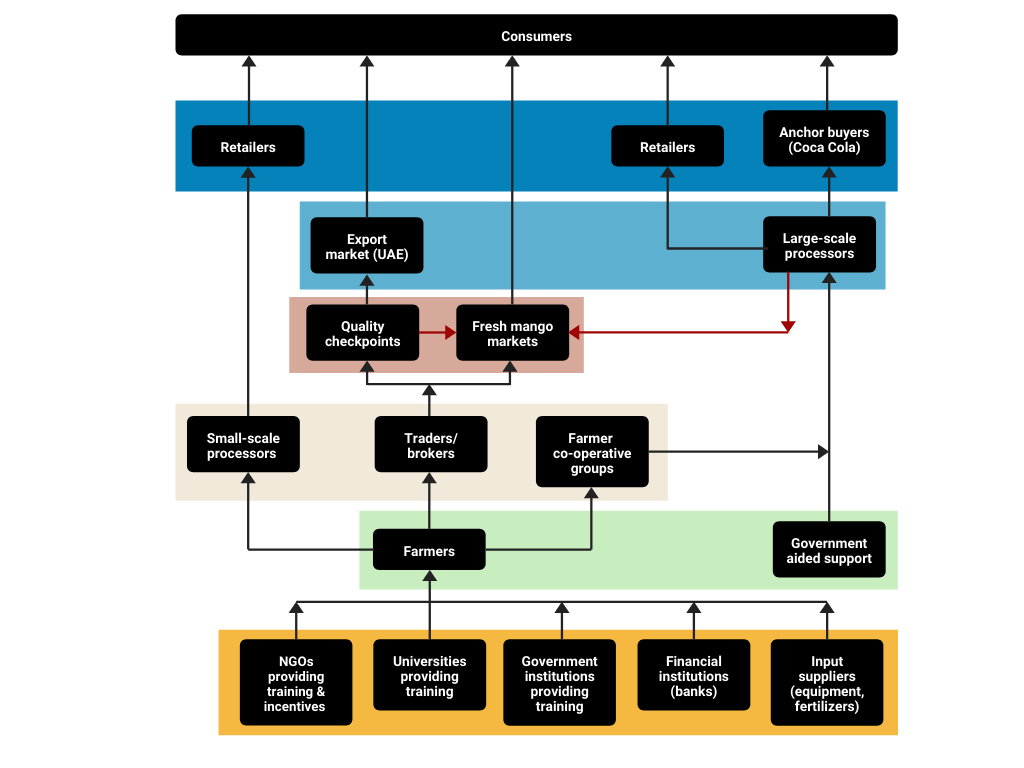

The data synthesized from the desk research and interviews shows that the value chain actors include farmers, government agencies, NGOs, academic institutions and processors. It was noted that the postharvest losses occur throughout the value chain, beginning right after harvesting, through transportation to the fresh mango markets and even during processing. Nonetheless, the volume of mangoes lost at the various stages in the value chain has not been quantified across the country, hence, it is difficult to determine the exact volume lost. The losses were found mainly to be the result of a lack of suitable technologies for the postharvest handling and production of a wider range of mango products.

Additionally, a number of processing technologies were identified. These technologies are currently used mainly by small-scale processors, self-help groups and some farmers to make products such as mango juice, mango leather and dried mango slices. However, the use of some of these technologies came with challenges which affected the quality of the mango products produced.

To achieve a significant reduction in mango postharvest losses in Kenya, new technologies have been proposed in this research to offer small-scale processors a wider pool to choose from to process mangoes. Also, some of these technologies open the way for new avenues that have not yet been explored in the mango processing sector in Kenya.

Finally, it is proposed that the value chain actors consider the adoption of a circular economy to allow for the use of the by-products from mango processing for the production of other high value products like pectin and polyphenols. These can be used in other food and cosmetic applications, thereby creating new markets for the mangoes.

Click here to view the full report.

Mango Value Chain in Kenya

This research was completed as part of the 2020 E4C Fellowship program. Learn more about the Fellows who worked on this research collaboration by connecting with them on LinkedIn: Bezalel Adainoo, Behirah Hartranft, Jonathan Kemp, and Nishant Agarwal.