Core Technology Fluid Flow Analysis

Nth Cycle sees an opportunity to draw the resources needed for the energy transition from electronics waste, scrap yards, and more efficient mines. The electro-extraction solution of Nth Cycle is an alternative to hydrometallurgy and pyrometallurgy and supports battery manufacturers, critical metal recyclers, miners, refiners, and electronics manufacturers. Rather than using large, greenhouse gas-emitting furnaces or harsh chemicals, the technology uses only electricity to transform the outputs of electronics recycling and waste from existing mines into high-quality, critical minerals ready for use again.

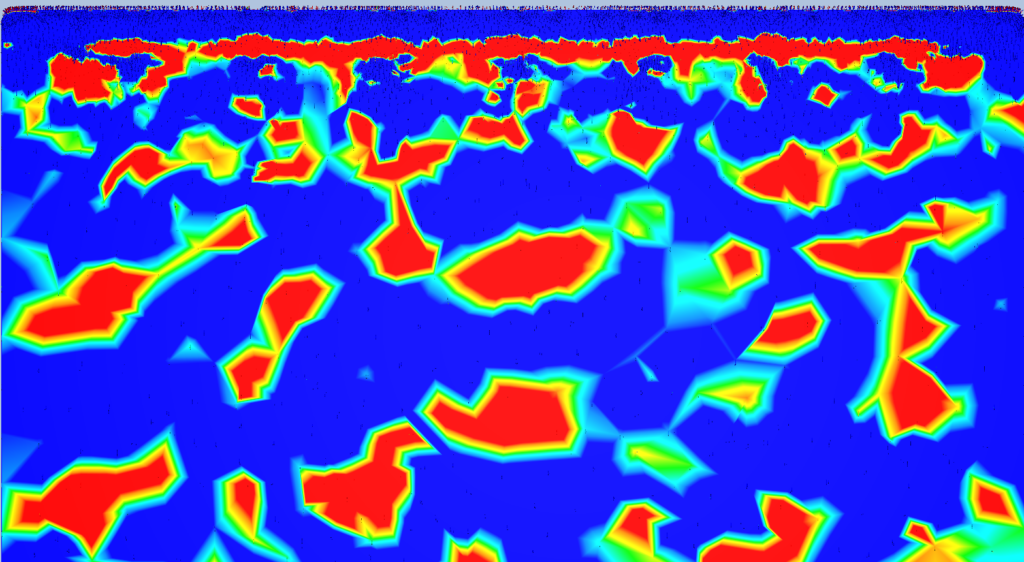

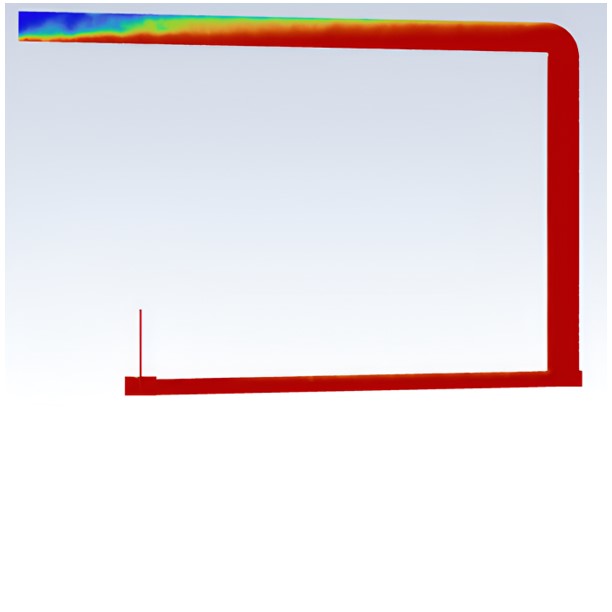

The aim of this project was to establish a computational fluid dynamic model for the fluid flow within Nth Cycle’s electro-extraction core technology that can be used to advise future designs and modifications to the cavity sizing and flow rates. This required an extensive review of prototypes and models of existing solutions to identify gaps/opportunities, conducting software surveys to understand tools available for the simulations, and creating clear CFD workflow – prioritizing important aspects and settings that need to be respected to achieve feasible results.

The Autodesk Foundation has sponsored the project by facilitating expert consulting, training, and tools for CFD simulation of fluid flow inside the system.