Refining Modules in Gas to Liquid Plant to Facilitate Containerization

When crude oil is extracted from underground and natural gas is brought to the surface, particularly in areas with limited infrastructure, this gas is burned off either at the top of a large stack or from a pit in the ground, often with devastating effects on local communities. In addition to the noise and light, flaring emits black carbon, methane, and volatile organic compounds, which are dangerous air pollutants. Natural gas flaring is both a waste of potential energy and a significant harm to the environment. It is estimated that the total natural gas flared every year globally amounts to around 140 billion cubic meters (IEA 2021). There are 16,000 gas-releasing flaring sites across the globe.

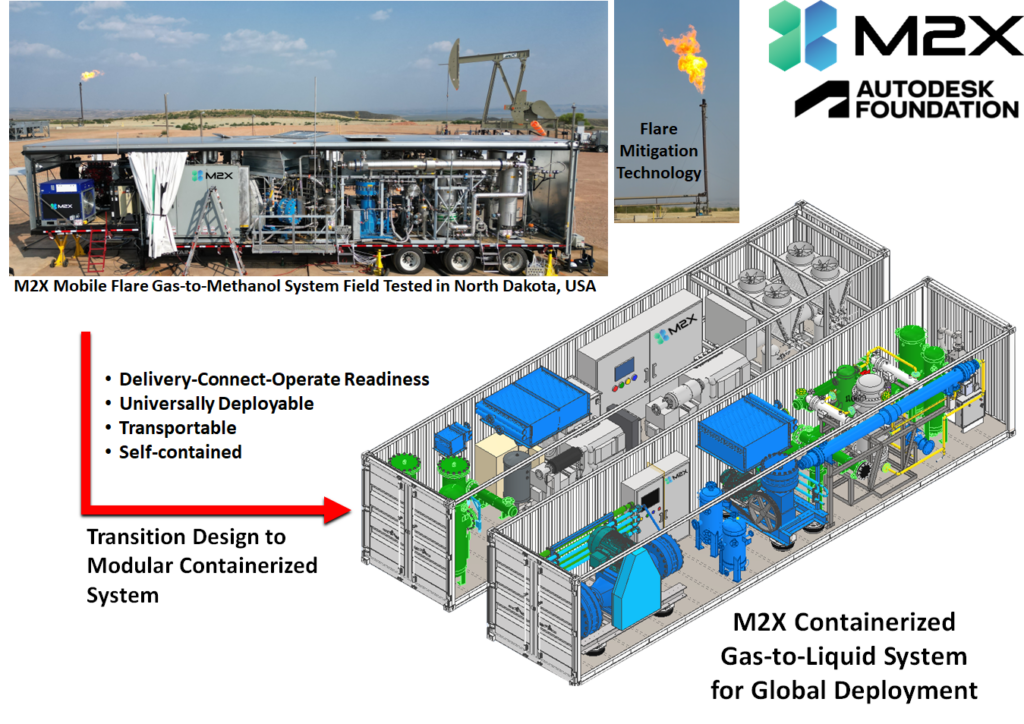

M2X aims to be the leading global supplier of small-scale modular, autonomous gas-to-product systems. M2X has developed a novel approach to green methanol production using what would otherwise be a waste stream: flare gas. The solution will mitigate significant volumes of GHG emissions by eliminating methane leakage through flare stoppages.

As part of this objective, this project supported modeling the containerized M2X gas-to-liquid system to enable rapid global deployment to gas flaring sites around the world. The project involved optimizing CAD layouts creating 3D models of mechanical equipment, piping, structure, and photo-realistic renderings. This step resulted in an extensive improvement in the performance of the container solution, providing detailing for manufacturability and adaptability to the reduced space.