Improving Engineer-Architect Communication and Workflows for Bamboo-Based Construction

Living up to BamCore’s goal of “reduce carbon, cost, labor, and time,” this project’s purpose was to simplify BamCore’s bamboo panel design process by opening a new communication channel between the architect and the engineer. This interaction has been made possible by implementing a new feature of the BIM procedure with Revit and Robot software from Autodesk.

The goal was to link the architectural designs of BamCore’s bamboo-based prime wall solution with the calculations and verification procedure conducted by the engineers. To get started, we surveyed our engineer collaborators to understand their design methods and needs, gathering information on how to make BamCore’s design procedure more efficient.

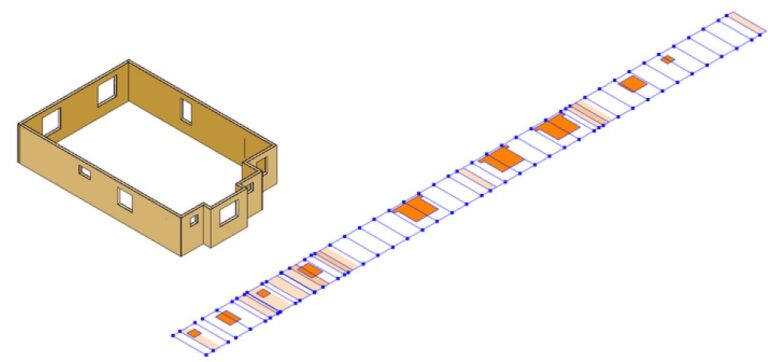

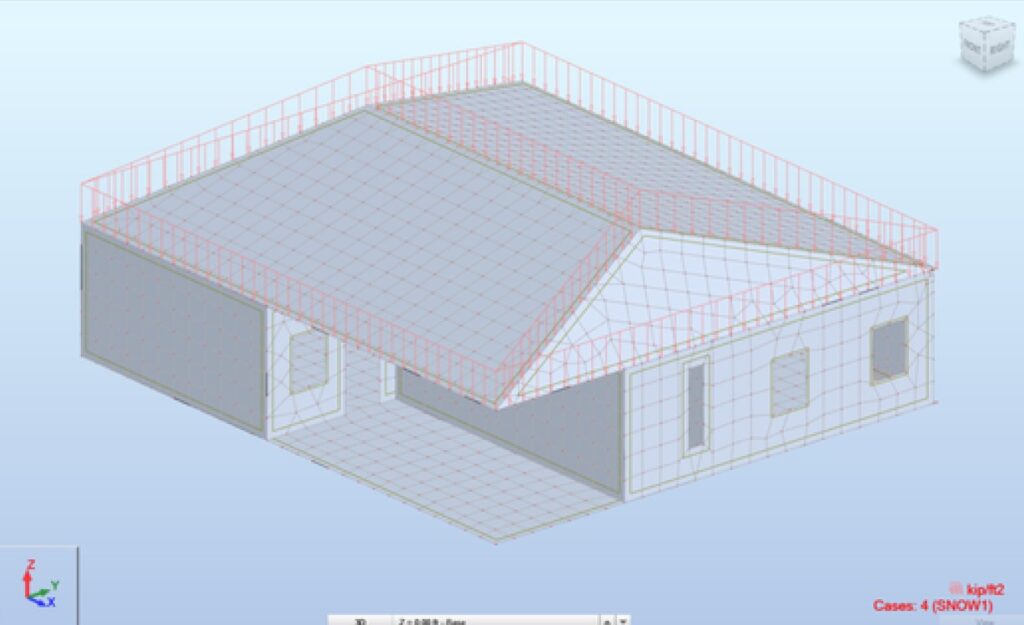

We realized the engineering team was very attached to their calculation methodology, yet they struggled with the translation of an architectural design to a structural design. It was noted that the best way to gain efficiency could be to enhance a workflow to upgrade the architect-engineer communication. We explored replacing conventional communication channels such as Autocad with a new Revit to Robot workflow. This new procedure allowed us to cut time on technical exchanges, using the model as the main support. The Robot model also allowed us to obtain the calculation results, such as shear efforts and deflections on the bamboo panels. Engineers can, from this output, verify the panel’s resistance and whether it meets design criteria.

The workflow proposed opens the door to a new design perspective. On this basis, architects and engineers are no longer isolated agents of the design process but a workforce that collaborates within the same model, pushing each other into new ways to achieve a more efficient and sustainable design.

Meshed Robot’s BamCore model with an implemented service load. Attribution: BamCore