Project Outcomes

This project aimed to design and simulate an aerodynamic grain cleaner that, on fabrication and optimization, will be used by rural farmers in India to produce market-ready and high-quality grains for the end users. The grain cleaner is expected to handle grains like corn, wheat, and pulses of varying sizes and moisture content. The project will increase profitability for the farmers, ease the strenuous conventional grain cleaning processes, and reduce the high cost of alternative grain cleaning processes currently in use.

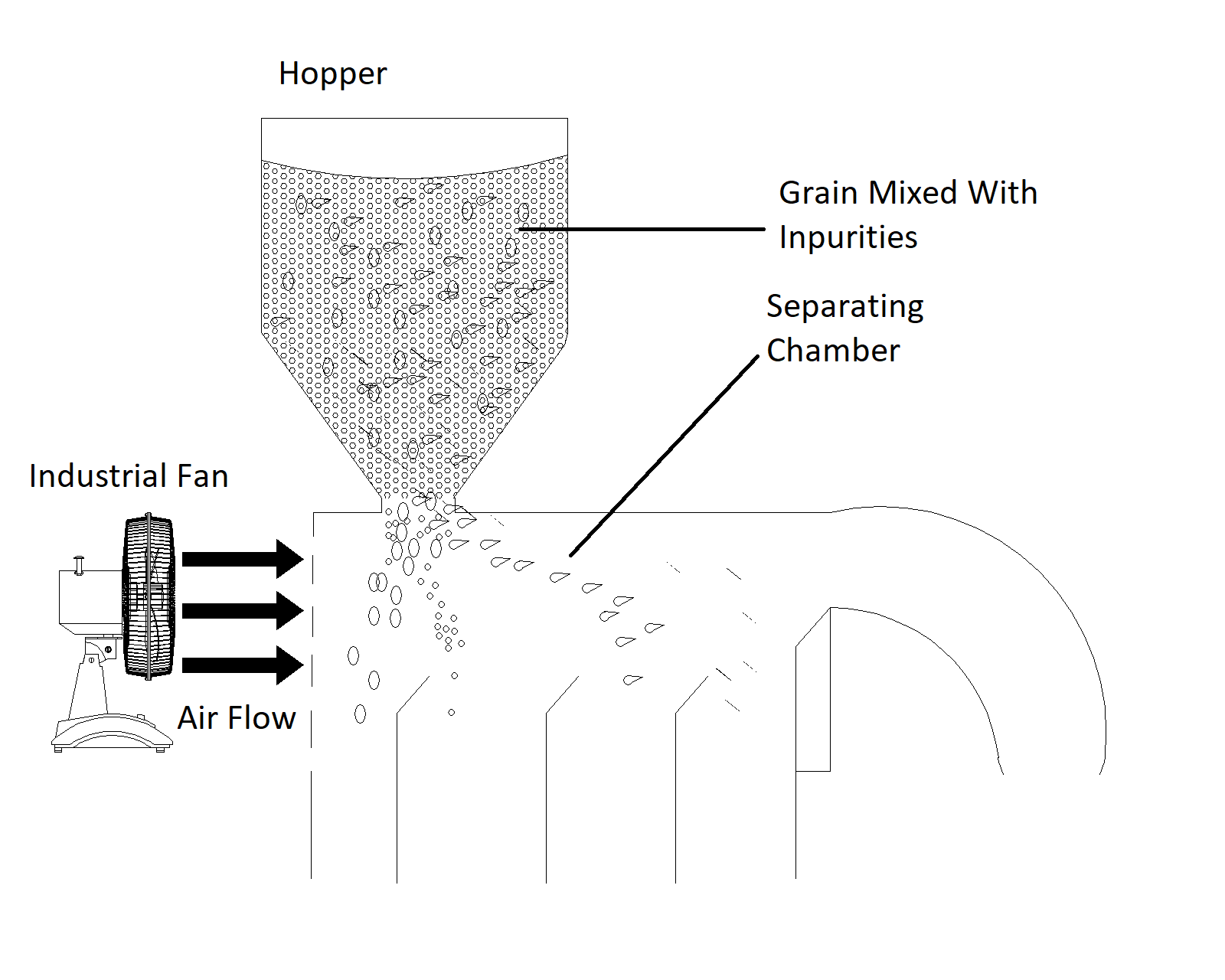

The design started with market research to understand the end user needs, which was then translated to the design concept used as the basis for the design process. The design process includes design analysis, calculations, drafting, and simulations. The equipment consists of five main components: an axial fan, a hopper, adjustable shutters, a separation unit, and a machine frame for support. The speed of the fan is controlled by a variable frequency drive. The separation unit consists of a louvre to direct the flow of air from the fan at a suitable and effective angle. The separation unit is also made up of several trays, which aid in the collection of the grains and impurities. The adjustable shutter, which is a hand-cranked control mechanism, helps to vary the width of the discharge trays, which, along with the variable speed of the fan, will help in multiple-grain cleaning.

The selected machine components were drafted using Autodesk Fusion 360 and Autodesk Inventor. Comparative and feasibility studies on key parameters were conducted in Autodesk CFD, and the results were used to optimise the design further.

James Okwoche/S4S Technologies