Project Outcomes

The project aimed to develop a sensor-based hardware solution to determine the thickness of frugal yarn, focusing on precision and reliability in measurement. The goal was to create a system that could accurately assess yarn thickness while being user-friendly and cost-effective. To initiate the project, research on various sensor technologies was done with the laser sensors being ultimately selected because of their superior performance compared to capacitive sensors.

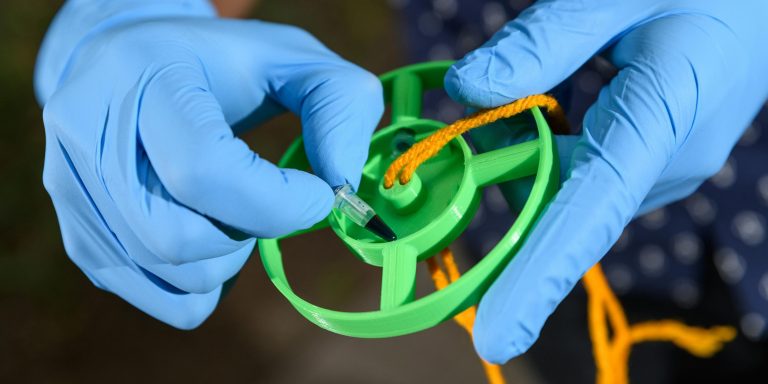

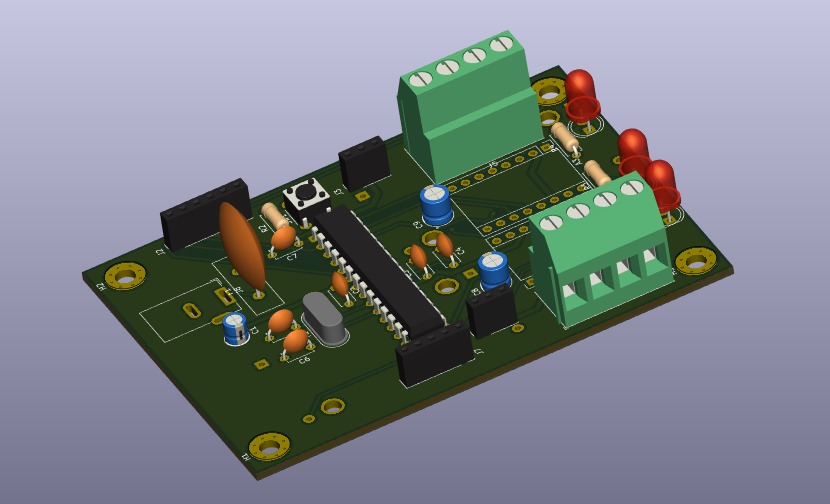

Using Fusion 360, the initial hardware layout was designed and a dummy board created as proof of concept. This prototype facilitated essential testing and validation of the design, ensuring it met the specific requirements for measuring yarn thickness. After the proof of concept was confirmed, better-suited sensors that enhanced the system’s measurement capabilities were sourced. A printed circuit board (PCB) that integrated these sensors was then designed, ensuring that the design was refined based on feedback and performance data gathered during initial testing. This iterative approach allowed optimization of the hardware for functionality and efficiency in yarn thickness measurement.

The key deliverables were the initial hardware layout, the dummy board for proof of concept, and the final PCB design incorporating the selected sensors. The refined hardware design significantly improved the accuracy and responsiveness of the yarn thickness measurement system, paving the way for future developments in this area

Stacy Kibarak/Resham Sutra