What do a pressure cooker, a bicycle gear hub and COVID-19 have in common?

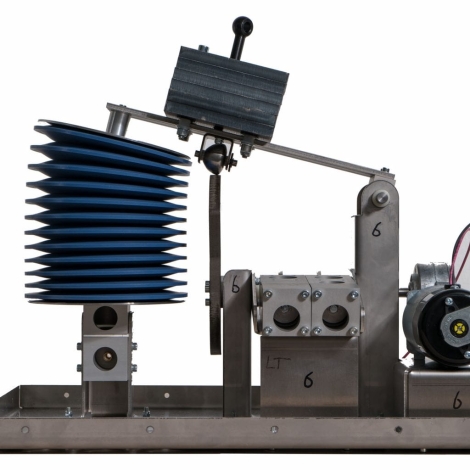

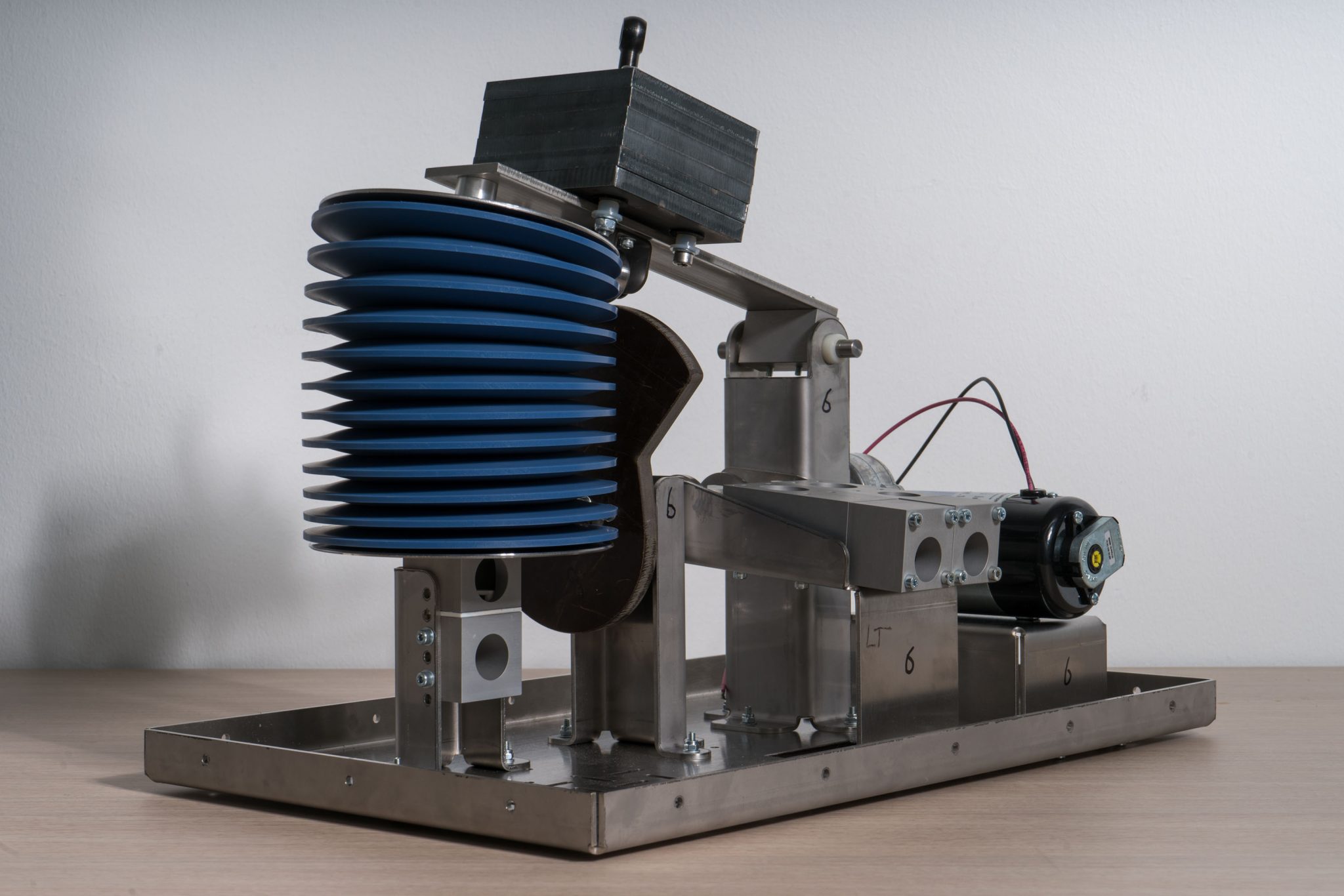

Four weeks ago, Gerwin Smit had the idea to resurrect a ventilator that was last used in the 1960s and enlist the machine in the fight against shortages brought on by the COVID-19 pandemic. Dr. Smit, who is an assistant professor of biomechanical engineering at Delft University of Technology in Delft, Netherlands, had his eye on the East-Radcliffe ventilator. The ventilator’s design stands out from others in use now, as this one is fully mechanical – no digital displays, no mobile connections. And, importantly, it is built with widely available parts. With some research, Dr. Smit found a model of the ventilator at the Boerhaave science museum.

Museum officials agreed to bend their rules in light of the urgency of worldwide ventilator shortages, allowing Dr. Smit’s team to switch on the museum piece. It appeared to be working even after 60 years. That same day the researchers loaded the ventilator into the back of a car and drove it to Delft Technical University.

Disassembling the ventilator revealed some surprises. The machine is cobbled together with parts from other machines. A gear hub controls the ventilator’s speed, performing a similar function to the one for which it was originally built as the internal gear in a Sturmey-Archer bicycle. And a pressure cooker is the ventilator’s humidifier. The parts list was a promising base for a robust and easy to use ventilator, built from parts that are available all around the world.

Dr. Smit and colleagues drafted a 40-member team of researchers, students and technical support staff. With the help of doctors, intensivists and medical reservists, the museum piece was revived into a modern emergency ventilator for COVID-19 patients.

The ventilator is designed such that it can be built and repaired locally. It is suitable for use in any medical setting, but especially apt in countries with fewer resources. To date, one mechanical ventilator has been sent to Guatemala to function as example model. The Roosevelt Hospital in Guatemala City and the manufacturing company Talleres Hernandez are exploring options for local production and distribution.

In the meantime, the Delft team is working to expand international collaboration. Organizations in multiple countries have shown interest in the machine and Dr. Smit’s team has shared information with peers in Colombia, Honduras, Panama, Costa Rica, Peru, Ukraine, Kenya, Nepal and Peru.

The mechanical ventilator’s plans and construction guide are open source, published on Github and free to use. By sharing these technical drawings and assembly manuals free of charge, more parties around the world can participate in the design and manufacture of mechanical ventilators.

Meanwhile, the Delft team is at work on the next version of the ventilator.

More information about the project can be found on www.projectinspiration.nl. The website shows a link to the open-source page. Are you interested in a collaboration with Project Inspiration? Please send an email to info@projectinspiration.nl.

About the Author

Vera Kortman is a student of mechanical engineering at Delft Technical University and a member of the Project Inspiration team. Her research interests are in biomechanical design and medical engineering.