Mayari Peréz has coordinated the opening and operation of a new makerspace at Universidad del Valle in Guatemala since she graduated and concluded her term as a Research Fellow at Engineering for Change in 2017.

“I think the fellowship showed my potential to work on diverse projects, time management skills, ability to write articles and gave me more insight into engineering for development, Maya says. “Being in a university, I’ve had the chance to help out students with projects that are related to rural communities or in the development sector.”

“I think the fellowship showed my potential to work on diverse projects, time management skills, ability to write articles and gave me more insight into engineering for development.”

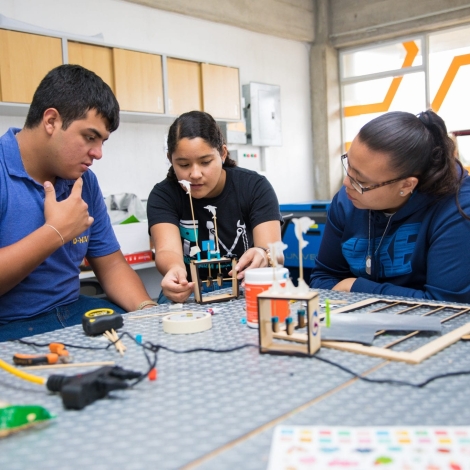

The space is the first of its kind in Guatemala, an academic facility modeled after those found at MIT and Stanford in the United States. Maya organized the creation of the space early in 2018 and students began using it in April. Although the Mechanical Engineering Department manages the space, it serves students and faculty from all disciplines.

In students’ hands, new creations are capturing a piece of their place in the world. Some technologies may not be out of place at any makerspace around the world, such as a new board game, or a custom animatronic hand with 3D-printed fingers and motors that move them. Other projects, however, seem rooted in Guatemala, built to meet the country’s unique challenges.

See also: How to Make a 3D-Printed Corn Sheller

A group of students used the space to print corn shellers, for example. And another student experiments with products made from upcycled plastic bottles. That project has two phases, the first is to devise methods for making plastic-bottle business cards and name tags with the space’s laser cutters. The second phase is to use those products to attract funding for a venture that would transform bottles into roof tiles. Maya offers guidance on these kinds of projects, drawing on her experience in the fellowship.

“I’m not working directly on development engineering, but students are, and I can share information, steer them to the Solutions Library and guide them a little bit,” Maya says.

Three groups of students are working on food dryers, a technology that could increase incomes and decrease food waste on Guatemala’s many small-plot farms and subsistence gardens. Dryers also happen to be the technology that Maya studied to earn her undergraduate degree in mechanical and industrial engineering at the university.

“From my graduation project and experience with the fellowship, I was able to help them. And I showed them the Solutions Library entries on dryers,” Maya says.

Compare food dryers side by side with standardized product information in Engineering for Change’s Solutions Library

With the makerspace up and running, Maya can afford to split her attention between new projects. In one, she leads her department in community outreach.

“The mechanical engineering department has made a priority reaching out to young girls to motivate them to study engineering, so I’ve been organizing these activities,” Maya says.

“The university’s vision is that with these makerspaces we can reach out to local communities, train them and give them a space to create and innovate.”

In another project, Maya works with students at the University of California, Davis, to improve on prototypes built in 2017. Students built the prototypes during the International Design for Development Summit, each intended to improve the quality of life in rural Guatemala. Maya revealed those projects in an earlier post at Engineering for Change, Five Sustainable Home Solutions Co-Designed with Guatemalan Villagers.

Finally, Maya now collaborates with coordinators developing two new makerspaces at rural satellite campuses in Guatemala. One is on the tropical coast, the other is in the cloud-forested highlands.

“The university’s vision is that with these makerspaces we can reach out more to the local communities, help train them in different skills and give them a space to create and innovate,” Maya says. “So, right now they are installing and implementing, but hopefully next year they will be up and running.”

What kinds of products will emerge from these spaces when they are up and running? Maya has some ideas.

“Maybe they’ll develop tech for sugar cane production in the coastal area. In the highlands there are a lot of artisans making pottery, textiles, woodworking, so it might be interesting,” Maya says.

For more on Maya, other Research Fellows at Engineering for Change, and the fellowship itself, please see our Fellowship page. And see her discuss the fellowship in the video below.