It is impossible to install pricey ENERGY STAR equipment and rooftop green gardens in every home in developing countries, but smaller scale and more appropriate materials are available. And they can build sustainable, strong homes anywhere in the world. From design to construction to operation, the process should not only consider sustainability, but also the environment and the appropriate needs of the users.

The local community helped with the retrofitting process. Local engineers were trained and can be independent on future projects.

Well considered structural engineering can make homes sustainable. Structural engineering dictates the material and the geometry of the structure, which, in turn, dictate the resources and construction methods used in a project. By choosing the right materials, structural engineers can improve a project’s sustainability. And they can satisfy the needs and safety of a building’s users with innovative and appropriate designs. A key aspect of sustainable structural engineering is to keep the local community involved. Resources should be easily accessible to the building’s users and the construction process should be done with the community, ideally educating people to be self-sufficient.

Here are examples of projects that used innovative materials in sustainable and appropriate structural engineering.

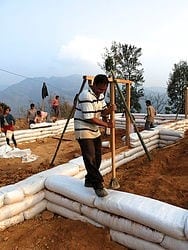

An earthquake-resistant home under construction in Haiti. Photo courtesy of E2E

Seismic retrofitting

Seismic retrofitting was used to rapidly repair and rebuild structures in Haiti after the January 2010 earthquake. Retrofitting is a cost-effective way (more cost effective than reconstruction), to improve upon existing damaged structures, in order to reduce accidents and deaths caused by future earthquakes.

In Haiti, several retrofitting methods were used to improve structural integrity, such as increasing the shear wall density to resist seismic loads on structures, repairing deterioration due to corrosion or sulfate attack, and strengthening ground conditions and foundations in liquefaction zones. Most importantly, the local community of Haiti also helped with the retrofitting process. Therefore the local engineers were trained and can be independent on future reconstruction or retrofitting projects. Build Change has made nearly 28,000 buildings safer in Haiti by using retrofitting techniques.

New construction in Haiti can also be earthquake resistant, of course, such as this project by Engineering2Empower.

Learn how to build this home in our guide: How to build a compressed-earth-block home. Photo courtesy of dwellearth.com

Compressed Earth Blocks

The Earth Block Resettlement Project in Mozambique used Compressed Earth Blocks (CEB) for building their resettlement structures. CEBs are comprised of mixed dry subsoil, clay, and waste aggregates, such as building rubble, compressed with machine press or hydraulic compactor at high pressures. CEBs are used in this project since they have a compressive strength that exceeds the requirements for regular cement blocks. Most importantly, they are sustainable since the earth blocks used only 8% cement, which helps to reduce carbon emissions. Because only soil slurry is used for bonding instead of cement mortar, the construction process is also faster and low technology can be used to manufacture them. CEBs also have better insulation properties than regular concrete blocks.

Source: Solaripedia

Trombe walls

The Druk White Lotus School in Ladakh, India, used Trombe walls as a passive solar design that optimizes thermal performance. Trombe walls consist of external walls made out of glass or plastic glazing panes and internal walls with high heat capacity. In between these two walls, there is air that separates them. The system works when the external wall absorbs heat through UV waves during the day and transfers the hot air to the insides of the building through internal vents during the night. This system is perfect in Ladkh, since Ladkh has 320 days of sunlight. Before Trombe walls were used, traditional fuel, wood, and kerosene were used, but were deemed hazardous since they gave off smoke that polluted air and caused health problems.

A Guatemalan community builds a school from plastic bottles. Photo courtesy of Hug it Forward

Eco-ladrillo bottle bricks

“Eco-ladrillo,” in which “ladrillo” means “brick” in Spanish, makes a fitting name for plastic bottles used in construction. Bottle walls were used in a projects in Guatemala when the non-profit Hug it Forward helped local communities build 12 schools for US$15,000 each.

And in the Dominican Republic, eco-ladrillos figured into a project organized by students from Humboldt State University and RevArk in 2011. The schoolroom, called the La Yuca Eco-Ladrillo, used eco-ladrillo walls made out of plastic bottles filled with renewable waste material, which were both accessible and locally available. The eco-ladrillo walls had less weight than traditional concrete walls, therefore it was less of a threat to safety if they collapse.

Source: firststepshimalaya.org

Earth bags

Woven polypropylene bags filled with locally available inorganic material and moist subsoil, called earth bags, were used to build an education center in Nepal. The bags were proven very effective, since the building, which was built five days before the 2015 Nepal earthquake, was still standing. The bags are designed to have internal stability and resilience against earthquakes due to its properties of self interlocking and consolidating moist fill inside. Concrete blocks, bricks, and adobe tend to collapse suddenly, as opposed to the earth bags. The bags are also connected by barbed wire and mesh for friction and tension resistance between bags.

Yan Chu is the lead engineering writer at Sturdy Structural. She loves to help people succeed in understanding difficult structural engineering concepts and getting their professional accreditation by providing structural engineering notes in her blog. By day, she works at a structural engineering consulting firm in Hong Kong.

For more on sustainable structural engineering, please see Earthship Biotecture’s Six Best Practices for Sustainable Architecture. And explore the Housing section of our Solutions Library for emergency shelters and earthen construction equipment.

EXCEL Coat is one such type of sustainable rooftop solution which offers a wide range of products including Coal Coat, StayCool etc which helps in maintaining the temperature of the interiors of the building. For any product query visit here econaur.com/store/excelcoatings