Within the next decade, people in off-grid villages may be able to make their own solar panels from cheap materials mixed with agricultural waste. MIT researchers who are developing the technology speculate on future do-it-yourself bags of solar panel mix, just add leaves, grass clippings or other waste from the yard or farm. Paint the mix onto a rooftop, connect wires and, voila, instant power. The biophotovoltaic panels would not be as efficient as today’s chlorophyl-free panels, but they would be dirt cheap and universally accessible.

“Potentially, this could be the way out of poverty for vast numbers: nighttime illumination is the bottleneck, if that can be provided inexpensively you can educate yourself by reading at night and then the sky is the limit,” MIT researcher Andreas Mershin told E4C in an email.

Democratizing science

To get to that green-roofed future, Mershin and his colleagues are counting on help from solar research labs worldwide. In fact, while their dream of paint-on plant panels has grabbed headlines recently, their real accomplishment is in the present tense: Thanks to their research, biophotovoltaics are now accessible to the average lab.

Before, biophotovoltaics research was a niche pursuit for well-funded labs with expensive equipment. The panels the labs produced generated tiny amounts of electricity, and even that was only when they were under specifically-calibrated laser light. Mershin and his team advanced the technology to create panels with about 0.1% efficiency in sunlight (or at least in lab conditions that approximate sunlight). Using their technique, labs worldwide can continue to develop the technology without the need for expensive equipment. The MIT researchers published their results in the open-access journal Scientific Reports with the hope that other research teams will stand on their shoulders and improve the panel’s efficiency.

“We have strived to ‘engineer the difficulty out’ of biophotovoltaics research in order to democratize access, hoping to start an efficiency and lifetime race by laboratories around the world,” the researchers write(pdf).

“Once the efficiency reaches about 1-2%, with a decent lifetime and an ultra-low cost, I think we may have a disruptive moment to celebrate: when producing and consuming solar electricity is possible in places never before,” Mershin says.

Nano forests of green power

Mershin and his team crossed the accessibility gap by solving two problems: how to stabilize the plant material and how to get a useful amount of electricity out of a panel.

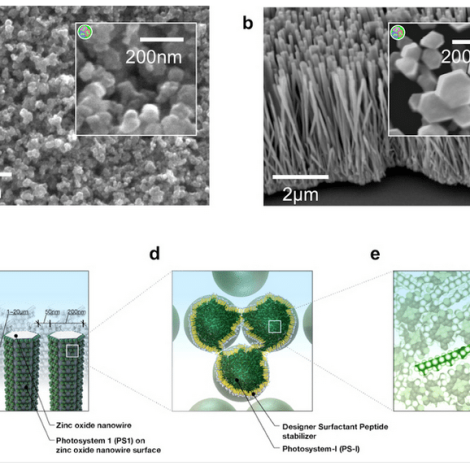

First, they stabilized the plant material. A suite of molecules called Photosystem I is at the core of photosynthesis, which means it is the foundation of Earth’s energy cycle. In the past, researchers have harnessed the molecules to produce a current. But in the process, the molecules became denatured (they “died”) and useless. Mershin’s team has shown how to stabilize dry Photosystem I with surfactant peptides and use it to both harvest light and separate the charge in a solar cell.

Second, the researchers boosted the panel’s efficiency. Rather than coating a flat surface with a layer of power-generating photosynthetic material, they built a nano-sized forest. Plants in the forest collect sunlight from the upper canopy down to brush on the forest floor. Emulating that kind of vertical efficiency, Mershin and his team coated a glass substrate with zinc oxide and titanium dioxide that self-assembled into a tiny forest of nanowires. The nano-forest increased the surface area of the panel. The result was a biophotovoltaic system that was about 10,000 times more efficient than those that had come before it.

Solar panels in a bag

In the future, Mershin foresees DIY solar panel kits in a bag, or even a wordless set of drawings showing how to make panels from materials that may some day be available off the shelf.

“We don’t know what the bag will eventually contain but we hope it is very little,” Mershin says.

“When we get to the first ‘Betty Crocker Solar Power Cake Mix,’ I think this bag will have to contain four things,” he says.

1. The stabilizing peptides that keep the Photosystem I from decomposing. Mershin’s team used commercially available materials in powder form, which are affordable for most labs around the world, but not for off-grid villages, yet.

2. Chemicals that make up the electrolyte. Mershin hopes other researchers find better, easier recipes than those his team used.

3. A transparent conductive coating for the sun-facing side of the panel. Mershin’s team used platinized glass, but the material could be made from something more accessible to off-grid villages. After some thought, Mershin imagined that this ingredient could be part of the “bag” itself, if the ingredients come in a tub with a transparent conductive plastic lid.

4. Chemicals to increase the surface area of the substrate. Mershin’s team used self-assembling nanowires, but he believes that even the first-generation DIY solar panel in a bag will not need those. Instead, there is a variety of cheap, semiconducting nanostructures available. “We’ve only scratched the surface of what’s possible,” he says. “A good example is zinc oxide nanowires that grow automatically when a zinc metal sheet is simply immersed in water containing a handful of non-hazardous, non-perishable, inexpensive chemical compounds.” Making nanowires sprout from a sheet of zinc like that is simpler than following a cake recipe, he says, and it doesn’t even require an oven.

The biosolar race is on

Before the bag is born, biophotovoltaics needs laboratories, Mershin says. “The problem up until now wasn’t so much that any fundamental discovery was necessary to proceed, it was that there are only a few labs around the world dealing with biosolar. Now we have a system that lets you design, build, test and optimize cheaper and faster and with less equipment and knowledge. So, that is key.”