The sight of bright orange flames, crackling loudly, and the smoky odor of burning hydrocarbons is an alarming sensory experience at oil and gas wells around the world. These natural gas flares are a wasteful necessity, and they are environmentally destructive. Flared gas, if captured, could be used to power homes, fuel vehicles, or create valuable products. Instead, it releases pollutants into the atmosphere, contributes to climate change and poses health risks to nearby communities. Modular gas-to-liquids plants (GTL plants) are a relatively new technology scaling up now as a solution.

This gas flare is at Permian Basin, Eddy County, New Mexico (USA). Photo: Blake Thornberry (CC BY-NC-ND 2.0)

Why flare gas?

Wells flare natural gas to burn off excess during oil extraction. The burn is a necessity due to a lack of infrastructure. There is no way to capture and use the gas effectively. Gas flaring contributes to greenhouse gas emissions and represents a huge waste of valuable natural resources.

In 2023, the World Bank’s Global Flaring and Methane Reduction Partnership estimated that on an annual basis, 148 billion cubic meters of natural gas goes up in flames at wells across the globe. The data from the Global Gas Flaring Tracker identified the top 10 countries flaring the most gas based on volume. These 10 countries accounted for 75 percent of all gas flared globally: Russia, Iran, Iraq, the United States, Venezuela, Algeria, Libya, Nigeria, Mexico, and Saudi Arabia.

Understanding modular gas-to-liquids plants

INFRA’s M100 Gas-to-Liquids (GTL) pilot plant near Houston Texas opened in 2018. Photo: Sergezolotukhin (CC BY-SA 4.0)

The solution to end flaring is to install infrastructure that can capture the gas. The technology is expensive, but it has existed since the 1920s as gas-to-liquids (GTL) plants. GTL plants convert natural gas or coal into liquid hydrocarbons. The first commercial-scale plant was built by Sasol in South Africa in the 1950s. Interest in GTL technology grew again in the 1990s and 2000s, leading to the development of larger facilities like Shell’s Pearl GTL plant in Qatar, which has been operational since 2011.

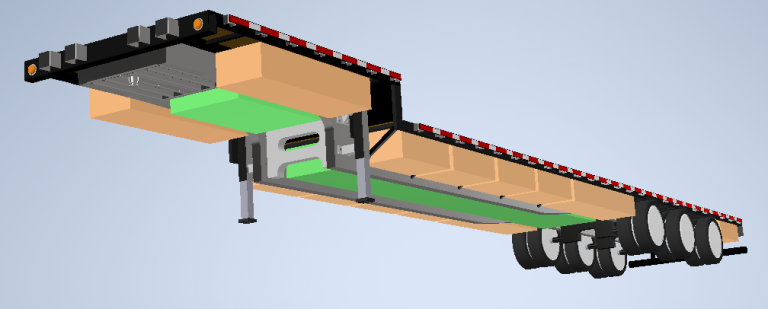

Building a GTL plant next to every oil and gas extraction operation would be too costly, however. In the last decade, a lower-cost, scalable option entered pilot and demonstration phases. Modular GTL plants are an innovation from the 2010s. They are compact, transportable units designed to convert natural gas into liquid fuels such as diesel, naphtha, and methanol. Unlike traditional large-scale GTL plants, modular GTL units are built in sections, or modules, that can be easily transported, assembled, and installed. Modular plants are compact, scalable, and can be deployed quickly to remote or underdeveloped regions where large-scale infrastructure investments may be impractical.

Picture this: a series of container-sized modules arrive at a remote flare site, they are quickly assembled and begin converting excess gas into methanol within days. The modular design allows for components to be easily manufactured, shipped, and installed. It’s like a high-tech Lego set for the energy industry.

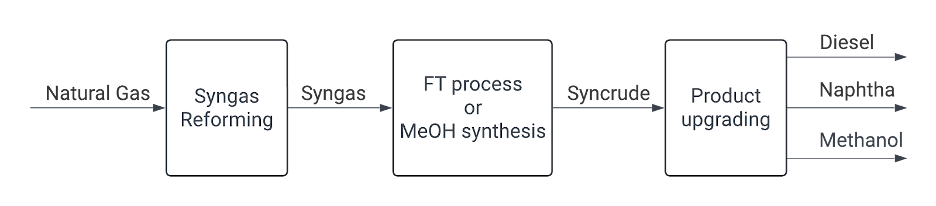

A simplified flow chart portraying the operation of GTL technology. Image: Williams Ibeh

The operation of modular GTL plants is a multi-step process. Initially, the raw natural gas undergoes pre-treatment to remove impurities such as sulfur and water. Next, the cleaned gas is converted into synthesis gas (syngas), a mixture of hydrogen and carbon monoxide, through a process called reforming. The syngas is then processed using catalysts to produce liquid hydrocarbons, typically through the Fischer-Tropsch process or methanol synthesis. Finally, the liquid hydrocarbons or syncrudes are separated into different products like diesel, a cleaner-burning fuel for transportation and machinery; naphtha, a feedstock for producing chemicals and plastics; and methanol, used in chemical manufacturing and as a fuel component.

The modular gas-to-liquids plant market

The GTL market has taken notice and it is shifting to favor small-scale and modular units. These plants can be constructed at a significantly lower capital cost compared to large-scale facilities, which can require investments running into billions of dollars. A recent forecast by Fortune Business Insights projects that the global GTL market, valued at (USD) $5.66 billion in 2019, will grow to $7.31 billion by 2032, with a Compound Annual Growth Rate of 3.72%.

A variety of small-scale GTL facilities, pilot projects, and demonstration plants have been announced or constructed. Some convert natural gas directly into other fuels, while others first convert natural gas into methanol before producing fuel. There are also initiatives that process biomass into liquid fuels.

Infra Technology Group: INFRA designed and built a proof-of-concept M100 GTL plant in 2018 near Houston (Texas, USA) to demonstrate its proprietary GTL technology. The plant featured low capital expenditure, compact size, modularity, and transportability, integrating INFRA’s proprietary Fischer-Tropsch system with other technologies. It was designed to produce 100 barrels of synthetic oil daily from 1 million cubic feet of methane. The plant’s compact design, with equipment occupying just 4,000 square feet, demonstrated efficiency and scalability.

M2X is a leader in low-carbon methanol production and methane emission reduction, converting stranded natural gas into low-carbon methanol. Their work addresses methane emissions from sources like oil flares, landfills and wastewater treatment plants. In 2023, they successfully field-tested their first commercial-scale, trailer-based methanol production unit, which validated their technology. They have scaled up their operations, with plans to deploy additional units in 2024.

Other small-scale GTL pioneers include: Gas Technologies LLC and Emerging Fuels Technology.

How to scale modular GTL plants

Scaling GTL plants will require supportive policy and financial incentives, and further research and development.

Government policies and regulations are key to advancing modular GTL technology, with incentives for reducing gas flaring and penalties for continued flaring encouraging investment. Collaboration among governments, environmental groups, and the private sector is vital to sharing risks, pooling resources, and speeding up deployment. Financial incentives for companies investing in gas capture and conversion, combined with penalties for flaring, can align economic interests with environmental goals and promote wider adoption of this technology.

Ongoing research and development are needed to enhance the efficiency and cost-effectiveness of modular GTL plants. Advances in catalyst design, process optimization, and materials science can improve performance and lower costs.

Modular GTL plants have the potential to reduce global gas flaring. They can transform wasted gas into valuable resources and create new economic opportunities. This technology could play a key role in the global shift toward cleaner, more sustainable energy.

About the Author

Williams Ibeh is a 2024 Engineering for Change Fellow and an engineer with a B.Eng. in Mechanical Engineering. He works as a product design engineer in the steel fabrication and manufacturing industry. As an E4C Fellow, Williams is supporting M2X Energy in their design of a transportable plant to reduce global methane emissions. The project is converting M2X’s trailer-based gas-to-methanol plant into a modular, container-based system for rapid global deployment.