Ten teams competed in a virtual undersea environment deploying their self-designed robotic craft to gather trash in the Extended Reality Challenge: Sustainability Innovations for Ocean Cleanup. The top three teams gathered 46-57 pounds (21-26kg) in three minutes in the competition hosted by the American Society of Mechanical Engineers and sponsored by Autodesk.

The competition wrapped up this month during ASME Engineering Festivals, concluding a months-long design phase. In the ramp-up to the demonstration, teams from around the world completed learning modules and built their virtual ocean-cleaning robots in Fusion. The first-place winners received (USD) $1,600 and all other placers won (USD) $800.

“I would just say that the efforts everyone put into this project makes me believe that the best way to help our planet is using those brilliant minds to develop new technologies than can fight the pollution across the world,” Jonathan Pacheco, the competition’s lead judge, says. “We as mentors and leaders are here to bring those ideas into reality and push the coming generations forward to achieve our goal of having a better and brighter future,” Pacheco adds.

The Top Three

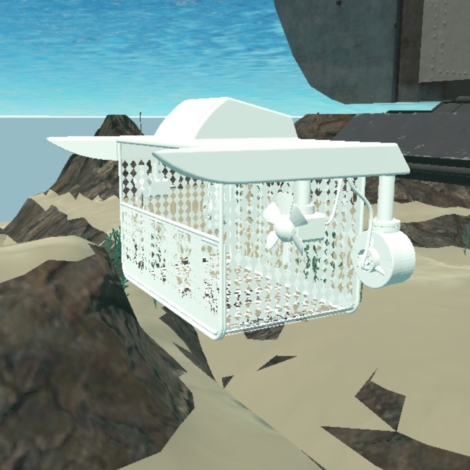

AquaGuardians from Assuit University, Egypt, won first place by a narrow margin. Their robot is pictured above.

NovaRover from Mar Athanasius College of Engineering in India, won second place. The team tied for highest marks in design innovations and held the second-highest total for sustainability integration. NovaRover also stands out as the team with the highest percentage of women at three out of six.

“Our victory lies in the smart decisions we made rather than sheer hard work alone. The learning modules provided by ASME, along with this competition, equipped us to make those smart decisions,” Novarover’s Team Captain Abu Fahad says.

Finally, Wave Rider, from the Universidad de Piura in Peru also placed.

Best use of Fusion & Module Knowledge

Team Wissen Marinos

India had a strong showing. NovaRover and another team from India, Wissen Marinos, from the National Institute of Technology Silchar, tied in the ‘Best Use of Fusion Software’ category. They had the highest marks for innovation in designing their devices.

“In essence, our experience throughout the competition bestowed upon invaluable lessons, equipping us with enhanced design proficiency, research skills and efficient problem-solving strategies,” Wissen Marinos Team Captain Pratisruti Buragohain says.

Team NovaRover

Also from India, Team Bluebird 1.0, at NIT Rourkela, earned top marks in several areas of its design report and took the ‘Best Demonstration of Module Knowledge’ prize. That prize stemmed from four learning modules in sustainable design and principles of Industry 4.0 that each participant took in the runup to the competition.

“Despite being new to the competition and facing challenges, our team never lost hope. We prepared extensively, following the guidelines and resources provided by ASME, including how-to videos, and learning modules. Our motto ‘Be brave enough to face failures until success makes its way for you’ drove us forward,” BlueBird’s Team Captain Prayash Kumar Behera says.

The learning modules are still available, free of charge. See the links below to register.

Robot design

The robots went after trash, but their design features were the furthest thing from it. These devices propelled themselves with water turbines, integrated artificial intelligence and machine learning into their software, and one design used a flax composite as a manufacturing material.

Teams designed robots that are submersible and programmed to gather trash while protecting marine life. The robots could identify marine life from trash and release the sea creatures that were accidentally gathered into collection bins.

Sustainability was a key factor in the competition. Several devices were solar powered, and teams prioritized the optimization of energy, space, and efficiency. The contestants described other sustainable aspects of their devices, including work to engage local communities in manufacture, incorporating recycled or discarded materials into the build, considering carbon footprints in operation and maintenance, realistic production budgets, and even outlining an approach to tourism through robotic ocean cleanup.

Freely available: Learning modules and Autodesk software for students

The contestants learned principles of design for sustainability, Industry 4.0 and data skills through learning modules they took in the leadup to the competition. Those modules are still available, free of charge. Explore the modules and register at the links below.