Project Outcomes

Gas flaring occurs when natural gas, a byproduct of oil extraction is burned off due to a lack of infrastructure to capture, store, or transport it. This process releases a substantial amount of methane, CO2, and other pollutants, contributing to climate change and harming local air quality. Economically, gas flaring represents a significant waste, as the flared gas could be utilized to produce energy or valuable chemical products, contributing to economic growth and resource efficiency (GFMR, 2023).

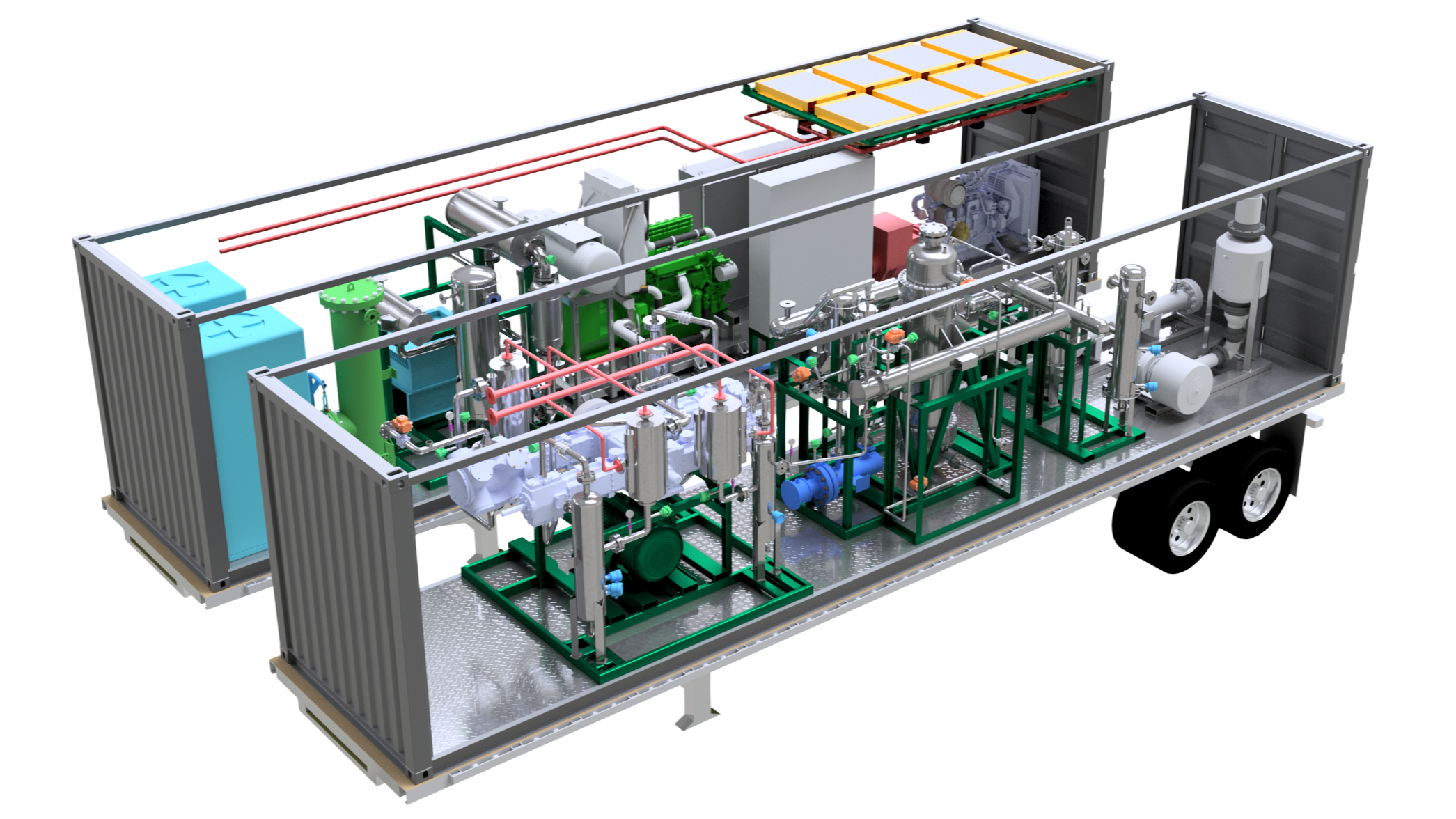

M2X Energy has pioneered the production of low-carbon methanol from stranded natural gas using a patented process. This technology captures natural gas emissions from major sources like oil fields, landfills, and wastewater treatment plants and converts them into liquid methanol. It presents a scalable and economically viable solution for managing greenhouse gas (GHG) emissions by repurposing stranded gas into methanol. In 2023, M2X achieved a significant milestone by building and demonstrating its first trailer-based commercial-scale unit in the field, validating the commercial viability of its technology. The company is currently expanding its manufacturing capabilities to deploy these units into the field.

Built on an existing framework, this project provided valuable engineering support focused on transitioning M2X’s trailer-based gas-to-methanol plant into a containerized system for rapid deployment worldwide. A modular (sub-skid) design approach was used to fit and integrate all the modules within two 40-feet ISO shipping containers. Significant attention was placed on the configuration of the modules, to optimize system layout, reduce capital costs, and enhance manufacturability, assembly, and servicing. This resulted in outputs, such as optimized equipment and piping designs, 3D models, structural analysis, renderings, and detailed engineering files, which would assist M2X with scale-up, manufacturing, and global deployment of their GHG mitigation technology.

CAD design of M2X’s Containerized Gas-to-Methanol System for Global Deployment (By Williams Ibeh)