Project Outcomes

Nth Cycle is an industry leader in critical metal refining, using patented technology to recover critical metals from end-of-life batteries, scrap metal, and mined ore that are needed for the electric grid, electric vehicles, and more. Nth Cycle’s modular Oyster system contains cells that are modified with each iteration, working to solve a challenge faced by the previous design. This requires a flexible workflow to avoid bottlenecks in the design process. The goal of this project was to reduce the design-build-test-learn (DBTL) cycle time to 4 weeks and the Right First Time (RFT) metric to 5% by developing improved Fusion 360 processes and workflows to accelerate rapid prototyping capabilities.

The project involved studying the current processes and understanding each team member’s functions and goals to develop improved workflows, template models, file organization, and other best practices. Time was spent with the team representatives from the design and manufacturing unit to review their typical designs and understand their needs.

The team faced challenges when organizing assembly structures that could be easily exported to an accurate and organized bill of materials (BOM). This made it challenging to order all the correct parts quickly and without errors for any given design.

The manufacturing team also experienced setbacks with certain CAM processes such as repetitive toolpath programming, and the need to replace milling tools attached to a set of 2D CAM operations, without having to redo the entire tool setup.

The main project work was to create and develop a Fusion 360 workflow and process guide, template models, file management and organisation best practices, CAM toolpath templates, and CAM standard processes, all customised to Nth Cycle’s specific team and process needs.

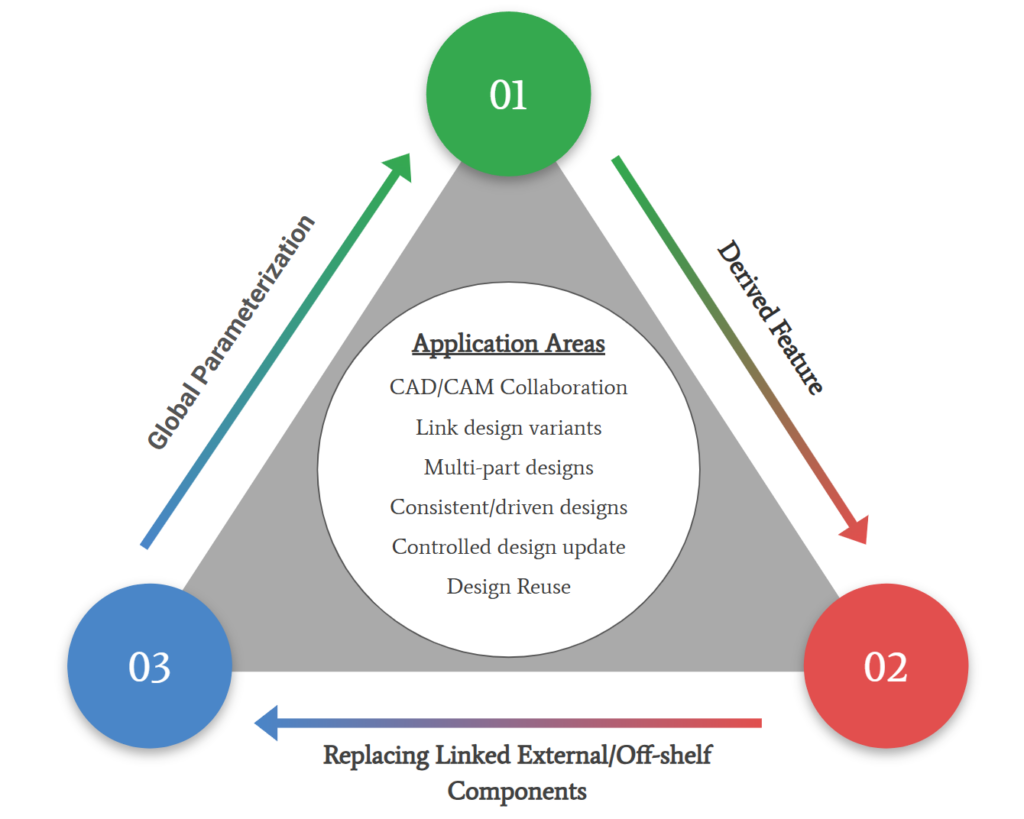

Applicable workflow for identified CAD challenges (Ofonime William / Nth Cycle)