Project Outcomes

By 2040, vast regions across the globe are projected to face high to extremely high water stress, with more than 40% of withdrawals exceeding available supply (World Resources Institute, 2023). Countries across South Asia, the Middle East, Northern Africa, and parts of Europe and the Americas will be particularly affected, intensifying the urgency for scalable, sustainable water generation technologies.

Against this backdrop, Uravu Labs is developing a renewable air-to-water device with a capacity of 2000 litres per day (LPD), designed to produce clean drinking water from the atmosphere using thermal energy. Within this system, the absorber subsystem is critical for capturing moisture, and its performance directly impacts efficiency, energy use, and scalability. Optimizing this subsystem is therefore essential to addressing future water scarcity challenges.

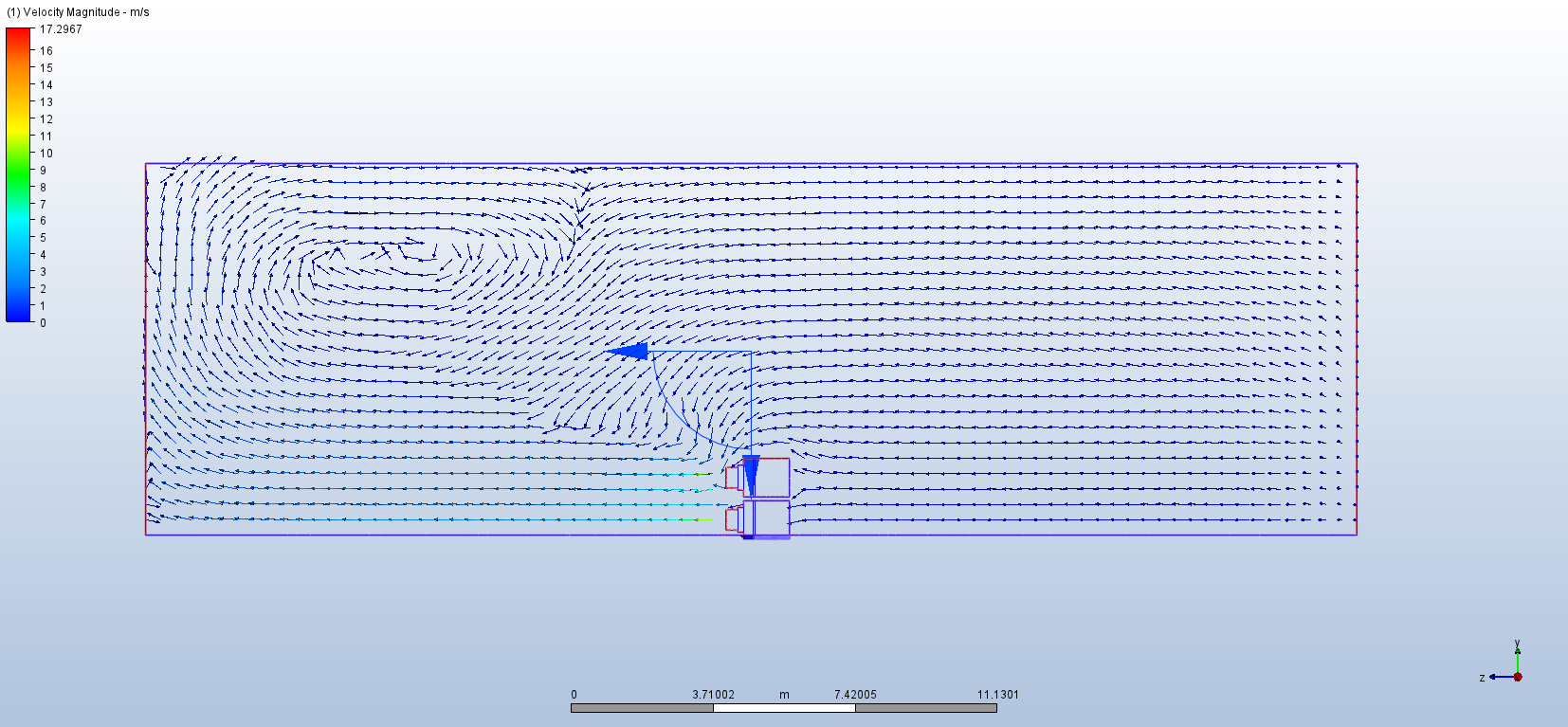

The objective of this project was to refine the absorber design using computational fluid dynamics (CFD). The focus was on identifying suitable packing materials and configurations, validating subsystem performance under realistic conditions, and addressing inefficiencies such as recirculation of dehumidified air back into the system.

The project advanced in several stages. First, baseline CFD simulations were conducted to characterize existing absorber performance under defined boundary conditions – pressure drop and flow rates. Second, airflow integrity analyses were carried out to identify and mitigate potential backflow of treated air.

Third, other parameters, such as temperature, humidity, and liquid phase, were introduced to replicate the actual conditions. Iterative modelling allowed the team to compare tradeoffs, refine designs, and converge on an optimized configuration.

The project delivered optimized CAD models of the absorber subsystem, detailed CFD simulation reports validating system performance, airflow integrity analyses, and documentation of design iterations with performance tradeoffs. The results provide Uravu Labs with actionable engineering data to improve absorber efficiency, reduce operational losses, and strengthen the foundation for commercial deployment of the 2000 LPD air-to-water device.

Key technology/tools used: Autodesk Inventor, Autodesk CFD

Velocity vector plot from Autodesk CFD showing airflow distribution and recirculation zones around the central absorber components (by Harsh Vyas)