ProdSmart Case Study for Apparel Manufacturing

ISAIC (Industrial Sewing and Innovation Center) is a national resource for those committed to positive impact through responsible production of high-quality garments and solutions centered around people, education, advanced manufacturing, and upward mobility for workers.

The apparel manufacturing industry has challenges in offering a standardized approach to workforce training. It requires timely worker skills updates as per technological enhancements. ISAIC is interested in implementing advanced techniques to improve manufacturing and reduce waste from the process by utilizing Autodesk ProdSmart software.

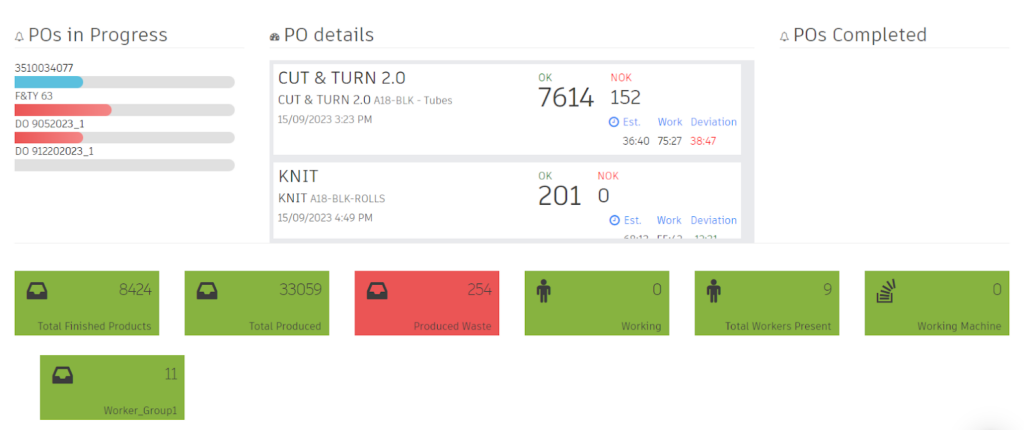

In this project, ISAIC aimed to measure all production records to improve the utilization of resources and increase the efficient use of natural resources for sustainable development.

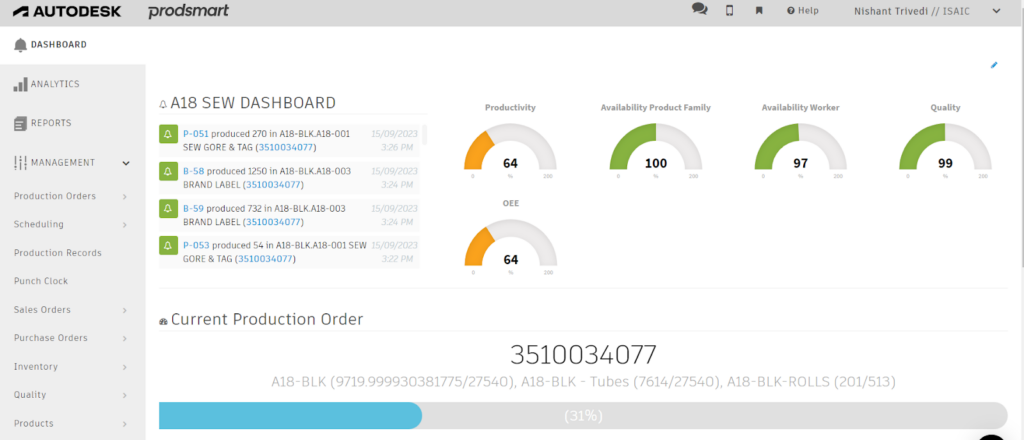

This project aimed to build out ISAIC’s production records and process workflows on ProdSmart. Research was conducted on inventory management and product development valuation, which includes raw material cost, labor cost, and equipment cost. The Fellow developed a customized analytics dashboard for individual product groups to measure specific data to take corrective actions and improve productivity and overall equipment efficiency. Additionally, maintenance requests, along with the recurring preventive maintenance schedule, were automated by analyzing the previous records. This improved machine availability.

Skills assessment and training requirement information was also developed in the software for stakeholders to stay up to date with technology changes in the industry. Therefore, production efficiency is set to improve by equipping employees with the required skill sets to operate specific machines.