Reducing Embodied Carbon in the Built Environment Through Bamboo-Based Material Usage Rules

This project developed a digital workflow to reduce waste material in implementing BamCore‘s bamboo based Prime Wall system. The company produces an environmentally sound bamboo paneling system that can be used in commercial and residential low-rise buildings. BamCore operates in a design-driven scenario where it is crucial to know which panelization rules lead to the least waste, thus reducing the systems’ carbon footprint. We, therefore, developed a digital workflow in Dynamo that will help BamCore optimize its building panelization process for reduced material waste.

The first step in developing the workflow was to understand the variables that come into play in defining the panelization of buildings. The variables identified include the location of windows and doors, whether or not the openings need lintels, the bamboo panel standard dimensions, and the location and quantity of walls. Most of these variables are not defined by BamCore but, instead, a consequence of project constraints for design and structural requirements. What can be determined, however, is the paneling start point, i.e. where to place the first panel in each one of the walls to be panelized. Consequently, the digital workflow developed uses the start point of panelization as the primary variable to define reduced waste production.

The digital workflow is intended to be a design tool that can aid the user in deciding how to design the panels for different projects. The waste material in this process is generated due to cutting the standard bamboo panels to fit defined wall dimensions. In the digital tool, the generated waste is automatically evaluated using custom nodes in Dynamo, both in quantity and quality. At the same time, the script also estimates the percentage of reusable waste pieces, representing the pieces that are large enough to be easily reused in other projects. The tool, therefore, allows for real-time feedback on how different panel star points affect the total waste generated in the project.

While the user can use the tool manually to try out different panel start points and variables, users can also automatically define the panelization star points for all the walls. Generative Design, a feature now available in Revit, can be used to automatically find the most optimal panel start point for all the walls in the project. Generative Design helps save time in defining the panel design for each partition in the project while ensuring that the least amount of material goes to waste.

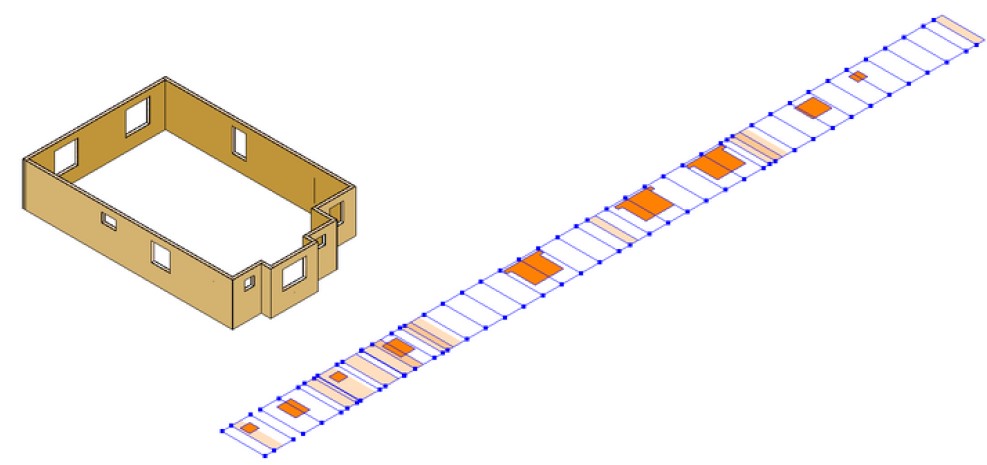

Original model and the panel design for the entire building envelope, highlighting the waste pieces from cutting the panels for openings and edges. Attribution: BamCore