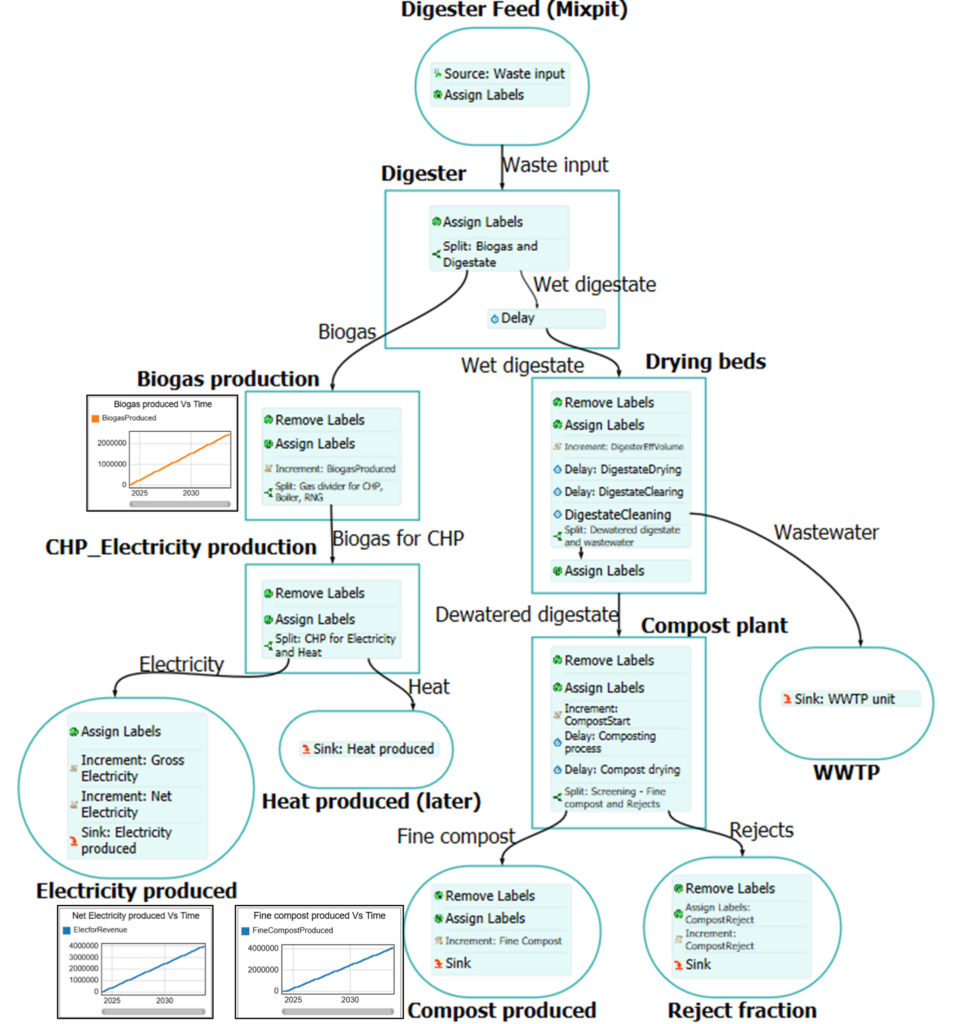

Safisana is initiating, designing, constructing and operating waste-to-resource factories in order to improve the sanitary conditions in low and medium income countries. This project focused on supporting Safisana with its business development activities, primarily TEA (technical – economic analysis). One of the core aspects of the TEA process is the quantification of material streams, for example, what are the expected outputs for a potential new factory, and which inputs would be required? This helps to make informed decisions at the early stages of the project pipeline.

This work focused on the modeling, using simulation software and spreadsheets. Previously, Safisana had been working with static models (spreadsheets) but aimed to expand to simulation models, enabling the addition of a time dimension. The results from these would feed directly into the financial models to support the business cases and decisions.

An in-depth evaluation was conducted to confirm the selection of a suitable simulation modeling approach as well as the software. This included extensive training in two softwares (Ventity & FlexSim). Following the selection of FlexSim software, a simulation model was built, with the output connecting to the existing financial models. The resuls were then validated by comparing the output with that of the existing static model.

The key deliverables of the project were a simulation model, a partner facing report with a user manual, and a public facing report. Additionally, a knowledge database was created with the gathered training resources. The outputs of this projects will support Safisana’s business development activities and informing future decisions.

Key technology/tools used: FlexSim, GSuite

Discrete event simulation model.

Attribution: Model created using FlexSim v.25.1.2 by Namrata Mhaddolkar