It is estimated that 1.6 billions tonnes of food, worth about $1.2 trillion, is wasted globally each year. Much of this waste goes to landfill, decomposing and releasing greenhouse gases. Additionally, the natural environment and water systems are being destroyed by approximately 200,000 Olympic-sized swimming pools’ worth of untreated wastewater every day.

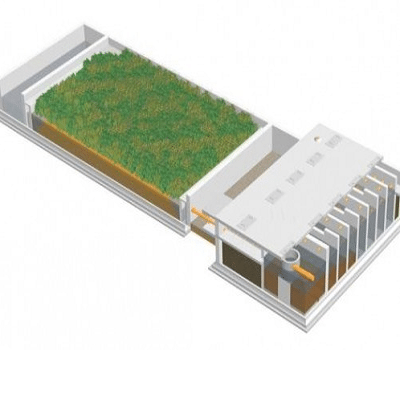

WASE aims to be a one-size-fits-all modular containerised wastewater treatment solution, allowing communities and companies to manage and benefit from their waste in a sustainable and self-sufficient way. Through an electro-methanogenic reactor (EMR) process the system can recover useful products from waste streams, including energy in the form of biogas, clean water, and fertiliser for agriculture.

The focus of the project was on further commercial validation through designing and developing a pilot system for implementation before a full system is introduced in 2022. Initial research was conducted into anaerobic digestion efficiency and enhancement, looking into three main areas; tank design, heating and mixing methods, helping to inform later design decisions. Working directly with the design team, calculations were carried out to determine parameters for heating and mixing requirements, in addition to design and development work on the overall system process layout and the fluid dynamics within the treatment tank. Once parameters were determined, quotations and advice were obtained from companies for components in order to develop accurate OPEX and CAPEX costings, as well as the preliminary CAD design of the system, which aids in design decisions for manufacturing and assembly.

With the implementation of technology like WASE’s, emissions and harmful pollution from waste streams can be significantly reduced, helping to work towards global initiatives for renewable energy, clean water and sustainable agriculture.

Figure: Rendering of WASE’s containerised system

E4C 2021 PROGRAM MANAGEMENT TEAM: Mariela Machado, Senior Program Manager; Grace Burleson, Research Manager; Marilynn Holguín Clover, Program Coordinator; Jonathan Kemp, Program Associate

ADVISORS AND COLLABORATORS: Aeran Jenkinson, Design Engineer; George Fudge, Design Engineer; Llŷr Anwyl, COO; Faryal Rohail, Project Manager; Isabella Bulmer, Strategic Partnerships; Kyle Bowman, Senior Biochemical Engineer; Marcelo Elaiuy, Senior Biochemical Engineer; William Gambier, CTO; Thomas Fudge, CEO

This research was completed as part of the 2021 E4C Fellowship program. Learn more about the Fellows who worked on this research collaboration by connecting with them on LinkedIn: George Kelly and Elizabeth Collins.

No Comments.