Agriculture

December 26, 2023

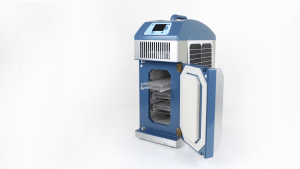

EcoFrost Micro Cold Storage

Read SolutionImplemented by

Ecofrost Technologies, a subsidiary of Ecozen.

Updated on January 20, 2024

·Created on August 27, 2015

ADRA Cold Climate Biodifester is a biodigester that uses straw and manure to produce biogas inside a fermenter compartment insulated with rice-shell ash or an equivalent material.

The Cold Climate Biogas Plant is designed and implemented by the Adventist Development and Relief Agency (ADRA) to operate in harsh climates that would incapacitate traditional plants. The digester is a fixed dome, in-ground concrete design and is part of a larger system that includes a greenhouse. The system is low cost and built for households in developing countries.

The product cost is between ~500 – 800 USD depending on local prices for a 5 m3 system. Interest-free loans are available through ADRA for regions with very cold climates. In many cases the construction material is provided by ADRA or through a government agency. Typically, the beneficiary contributes the labor for the project and ADRA provides the training and instructional materials. Users receive assistance from ADRA during the process where needed.

Target SDGs

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$800.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

ADRA has partnered with the Thermal Institute of the Austrian National Academy of Sciences in the development and implementation of the product. The academy has promoted and replicated the design throughout the Democratic Peoples' Republic of Korea (North Korea). Other NGOs also develop the plant in Nepal and Afghanistan including the UNDP.

Competitive Landscape

Direct competitors include SimGas Biogas Milk Chiller, Sistema Biobolsa, Flexi Biogas BG5, and ARTI Biogas Plant.

Countries

Bhutan, China, Korea (North), Mongolia, Nepal

Manufacturing/Building Method

The product is individually manufactured.

Intellectural Property Type

Open-source

User Provision Model

The product is supplied throughout North Korea (DPRK) through ADRA and the National Academy of Sciences. Advertising of the design is performed online and through DPRK newspapers. Interview with representative

Distributions to Date Status

As of July 2016, ADRA has constructed roughly 10 systems and the UNDP has constructed over 100 systems. Systems constructed by other entities are known to exist but have not been quantified.

Output energy product

Biogas

Average daily biogas production (m3/day)

3-5 m3/day.

Description of waste source(s)

Human, animal, and organic waste

Waste input requirements (kg per hour or day)

160 L per day of organic matter. (The plant also requires 5.65 m3 of aerobic matter for heating, which should be replaced every 3 months.)

Description of other input requirements

Unknown

Other input requirements (amount per hour)

Unknown

System dimensions (m)

5 m3

Design Specifications

The system is designed for use in a greenhouse. The greenhouse has a footprint of 35 m2 and the digester has a volume of 5 m3. For gas production, about 0.16 m3 of anaerobic matter needs to be supplied to the plant. To properly produce heat, aerobic matter must be replaced at a rate of 5.65 m3 every three months. The plant can store 0.5 m3 of gas, requiring a plastic bag to capture the total 3-5 m3 of gas that the plant produces daily. Interview with representative The system is operable at temperatures as low as -15 °C (with greenhouse), gas output 4-9 m3/day, aerobic heating system 30-65 °C, anaerobic process <25 °C, system can digest human, animal, and organic waste.

Technical Support

Technical support is provided by ADRA . Interview with representative

Replacement Components

Replacement components are available. Interview with representative

Lifecycle

The product has an expected lifetime of 10 years or more, depending on the level of maintenance.

Manufacturer Specified Performance Parameters

Designer-specified performance targets include: durable and efficient.

Vetted Performance Status

Testing performed by NOVA Energy, Switzerland determined an average daily biogas production. Interview with representative ADRA's pilot study found that in cold weather (-20°C) the digester produced 0.6-1.0 m3 of biogas per day, and in warmer weather that increased to 1.2-1.5 m3.

Safety

Extreme caution is necessary when working with biogas. Adequate ventilation, appropriate precautions, good work practices, and adequate personal protective equipment will minimize the dangers associated with biogas. Wherever possible, digester-associated tasks and maintenance should be performed without anyone having to enter confined spaces, including pits.

Complementary Technical Systems

None.

Academic Research and References

Reed, E.P., 2004, Unlikely partners in the quest for juche: humanitarian aid agencies in North Korea. Towards a Peaceful Resolution with North Korea Conference.

Sin, H.Y., Heo, E., Yi, S.K., Kim, J., 2010, South Korean citizens preferences on renewable energy support and cooperation policy for North Korea, Renewable and sustainable energy reviews, 14(5), pp. 1379-1389

Lam, J., Boers, W., 2005, Report on the Feasibility Study for a Biodigester Support Programme in the Kingdom of Cambodia, SNV

Compliance with regulations

None. Design is adapted and adjusted to local standards in each country. No applicable international standards exist. Interview with representative

Evaluation methods

The manufacturer cites a feasibility study by ADRA as the evaluation method. Interview with representative

Other Information

ADRA is also committed to other SDGs and disaster relief activities.

Agriculture

December 26, 2023

Implemented by

Ecofrost Technologies, a subsidiary of Ecozen.

Agriculture

February 20, 2024

Implemented by

Stone Cold Systems

Agriculture

December 16, 2023

Agriculture

December 11, 2024

Implemented by

Ambros Huber

Agriculture

June 23, 2024

Implemented by

Bajaj

Agriculture

November 30, 2024

Implemented by

El Fuego del Sol

Agriculture

January 31, 2024

Implemented by

Grundfos

Agriculture

December 21, 2023

Implemented by

AID Foundation Inc. (AIDFI)

Agriculture

January 14, 2024

Implemented by

LuminAID

Agriculture

December 17, 2024

Have thoughts on how we can improve?

Give Us Feedback