Agriculture

March 7, 2024

NRG Insulated Block

Read SolutionImplemented by

Francis Kennedy

Updated on February 26, 2024

·Created on August 27, 2015

AECT Impact 2001A is a hydraulic compressed earth block machine that can produce 300 blocks per hour.

The AECT Impact 2001A Compressed Earth Block Machine is an automated machine that produces about 2,400 blocks per 8 hour day, powered by a 7 HP diesel engine.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 1: No Poverty

Market Suggested Retail Price

$33.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises, NGOs

Distributors / Implementing Organizations

AECT with dealers in South Africa, Egypt, Saudi Arabia, and other nations

Competitive Landscape

Direct competitors include CalEarth SuperAdobe, Hydraform M9, and Terrabric 2B.

Regions

Worldwide

Countries

United States

Manufacturing/Building Method

AECT individually produces products as they are ordered.

Intellectural Property Type

Copyright

User Provision Model

The machines are distributed mainly through aid organizations or through dealers in South Africa, Egypt, Saudi Arabia, and other African countries. Interview with representative

Distributions to Date Status

71 units Interview with representative

System Dimensions

206 x 173 x 130 cm3

Portability (yes/no)

Yes

Raw materials used

Earth, clay, sand and cement

Recommended water content (ratio)

Unknown

Induced pressure (Mpa)

5.6 MPa

Power source

7.0 HP Yanmar diesel engine

Finished unit dimensions

30.5 x 15.0 x 5.0 – 11.5cm3

Rate of production (units/hour)

300 blocks/hour

Curation duration (days)

No earth block curing required

Suitable climate

Not suitable for cold climates unless necessary vapour barriers and insulation can be added. On their own ISSBs and CEBs do not hold up well to freeze/thaw cycles and have a low thermal insulation capacity

Design Specifications

The AECT Impact 2001A Compressed Earth Block Machine is a mobile unit, powered by a 7 HP 208cc OHV Power Horse Gasoline Engine (Yanmar) with 19.5 gallon capacity. Design specifications include:

• Unit Dimensions (L x W x H): 206 x 172.72 x 130 cm3, 15 cm road clearance.

• Weight: 743.89 kg

• Finished brick size (L x W x H): 30.5 x 15.0 x 5.0 - 11.5 cm3

• Finished brick weight: 4.1 - 8.1 kg

Technical Support

AECT requires 2 days of training in order to use the product. Failure to complete the training will result in a failure to validate the product warranty.

Replacement Components

According to the manufacturer, almost every part is replaceable. Interview with representative

Lifecycle

AECT has products manufactured in 1985 that are still in use. AECT representative states that if they are treated well, there is no reason for them to stop working. Most of the parts are replaceable, and the replaceable liners in the product prevent dirt from metal corrosion, the main reason for product deterioration. Since each user is required to be trained for the product, there is a 6-month warranty. No disposal information is available. Interview with representative

Manufacturer Specified Performance Parameters

Block production rate: Approximately 300 blocks per hour or 2400 per 8 hour day.

• Hopper capacity: 8 - 9 blocks

• Hydraulic system: 73.82 L capacity

Best Quality of block:

• Uniformity

• Strength

• Easy to Lay

• No variance in length and width

• Some moulds have adjustable thickness

Vetted Performance Status

Unknown

Safety

AECT requires 2 days of training in order to use the product effectively and safely. Failure to complete the training will result in a failure to validate the product warranty.

Complementary Technical Systems

Unknown

Academic Research and References

Graham, C.W. et.al., 2005, Movement Coefficients of Compressed Earth Masonry Units, 10th Canadian Masonry Symposium, Banff, Alberta, June 1 – 12, 2005.

Morony, J. J., 2005, Logged Data For Heat Wave- A Preliminary Report, Del Rio, Texas, May 31 – June 2, 2005.

Graham, C. W. et.al., 2005, Soil Block Home Construction, BTEC Sustainable Buildings III Conference, Santa Fe, New Mexico, October 17-18, 2005.

“Impact 2001 Series”, AECT Earthblock, accessed on February 26, 2024, https://aectearthblock.com/impact-2001a-series

New Mexico Government, 2021, New Mexico Earthen Building Materials Code, Title 14, Chapter 7, Part 4.

“Advanced Earthen Construction Technology, Inc.”, Better Business Bureau, accessed on February 26, 2024, https://www.bbb.org/us/tx/san-antonio/profile/construction-equipment/advanced-earthen-construction-technology-inc-0825-90008557/#sealclick

National Lime Association, 2006, Technical Brief: Mixture Design and Testing Procedures for Lime Stabilized Soil, National Lime Association, Arlington, VA

Compliance with regulations

AECT is a BBB accredited Business (A+) and follows 2009 New Mexico Earthen Building Materials Codes, Title 14, Chapter 7, Part 4.

Evaluation methods

Jar or sedimentation test: tests for suitability of soil for brick making.

pH Testing Procedure for Lime Stabilization

Fire tested by Firelab

Other Information

None

Agriculture

March 7, 2024

Implemented by

Francis Kennedy

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Agriculture

March 13, 2024

Implemented by

Watershed Materials

Agriculture

February 29, 2024

Agriculture

September 4, 2024

Agriculture

February 1, 2024

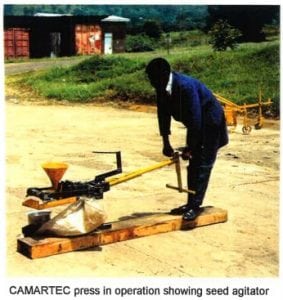

Implemented by

Centre for Agricultural Mechanization and Rural Technology (CAMARTEC)

Agriculture

August 14, 2024

Implemented by

Esther Mwangi, EsVendo

Agriculture

February 5, 2024

Implemented by

Gradian Health Systems

Agriculture

February 1, 2024

Implemented by

Lifeway Solar

Agriculture

February 16, 2024

Implemented by

Dairy Dynamics

Have thoughts on how we can improve?

Give Us Feedback