Agriculture

August 23, 2024

Maya Pedal Bicycle Mill

Read SolutionImplemented by

Mayapedal

Updated on September 18, 2024

·Created on October 13, 2020

The Agsol Solar-Powered Mill is a solar-powered system used to process a variety of crops including maize, cassava, sorghum, and millet.

The Agsol Solar-Powered Mills are a collection of agro-processing machines designed to process a range of dried cereals and tubers. Their machines are available in both DC and AC formats. The mills have zero fuel cost, and are designed to serve from the household to community level. The product is designed, manufactured, and distributed by Agsol. The product is designed in Australia, manufactured in Dongguan, China, and distributed through the head office located in Nairobi, Kenya.

Target SDGs

SDG 2: Zero Hunger

SDG 7: Affordable and Clean Energy

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises, NGOs

Distributors / Implementing Organizations

This product is distributed by the manufacturer.

Competitive Landscape

Direct competitors include Maya Pedal Bicycle Mill, Solar Milling Small-Scale System, and Multi-Crop Ewing Grinder.

Regions

East Africa

Countries

Kenya

Manufacturing/Building Method

This product is mass produced in China.

Intellectural Property Type

Trademark

User Provision Model

Users can obtain the product/service directly from the manufacturer or through its distributors, via pay-as-you-go (PAYG) digital financing.

Distributions to Date Status

As of 2020, 788 units have been distributed in the Pacific region.

Feedstock types

Cereals, dried tubers, maize, cassava, sorghum and millet

Feedstock rate (kg/hr)

30-85 kg/hr

Power source

Motorized

Energy requirement (W)

500-1,200 W

Portable or stationary

Stationary

Design Specifications

Agsol's Solar-Powered Mills are solar-powered agricultural machines, available in two variants: the Hammer Mill for milling flours, and the Rice Mill for milling grains, which differ in milling head size, screens, and exit gates. The dimensions are 670 x 360 x 700 mm for the Hammer Mill, and 480 x 290 x 925 mm for the Rice Mill. Both weigh around 40-45 kg. The product is offered with brushless DC and AC motor options and has a motor rating of 1.3-1.8 kW and for a 48V DC system, and 2.2 kW for an AC 1-phase or 3-phase system. The Hammer Mill has an efficiency of 39-50 kg/kWh and a production rate of 50-85 kg/hr based on maize milling with a 1 mm screen; production for cassava is doubled and millet is tripled. The Rice Mill has an efficiency of 90-115 kg/kWh and a production rate of 135-160 kg/hr.

Technical Support

Provided by the manufacturer.

Replacement Components

Unknown

Lifecycle

5-10 years

Manufacturer Specified Performance Parameters

Designer specified performance targets include: zero fuel costs, low maintenance, long machinery life, and easy to operate.

Vetted Performance Status

Testing was performed by the manufacturer to validate Agsol mill performance. Testing was performed on 1-phase to 3-phase systems and BLDC motors, and parameters of energy intensity, throughput, and noise levels were measured. The testing was conducted through a collaboration with Agsol and CLASP, although no independent third-party testing has been completed.

Safety

Potential hazards related to the operation of this product include sharp and fast cutting tools.

Complementary Technical Systems

The manufacturer also sells maize threshers and chaff cutters that can process cobs, fodder grass, maize stalks, and agricultural straws.

Academic Research and References

None

Compliance with regulations

None

Other Information

Agriculture

August 23, 2024

Implemented by

Mayapedal

Agriculture

February 21, 2024

Implemented by

ABC Hansen Africa

Agriculture

February 27, 2024

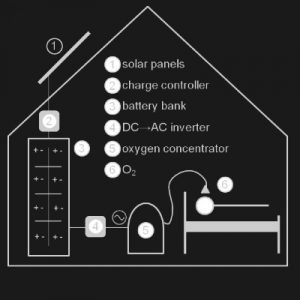

Implemented by

Solar Oxygen

Agriculture

January 19, 2024

Implemented by

Solar Street Lights Africa

Agriculture

August 21, 2024

Implemented by

Claphijo Enterprises

Agriculture

January 31, 2024

Implemented by

Grundfos

Agriculture

August 22, 2024

Implemented by

SunWorks

Agriculture

August 29, 2024

Implemented by

Graduate Farmer

Agriculture

February 1, 2024

Implemented by

Lifeway Solar

Agriculture

August 22, 2024

Implemented by

UC Davis D-Lab

Have thoughts on how we can improve?

Give Us Feedback