Agriculture

November 24, 2023

Pumani Bubble Continuous Positive Airway Pressure (bCPAP) Device

Read SolutionImplemented by

Hadleigh Health Technologies, and Rice 360

Updated on January 15, 2024

·Created on September 9, 2020

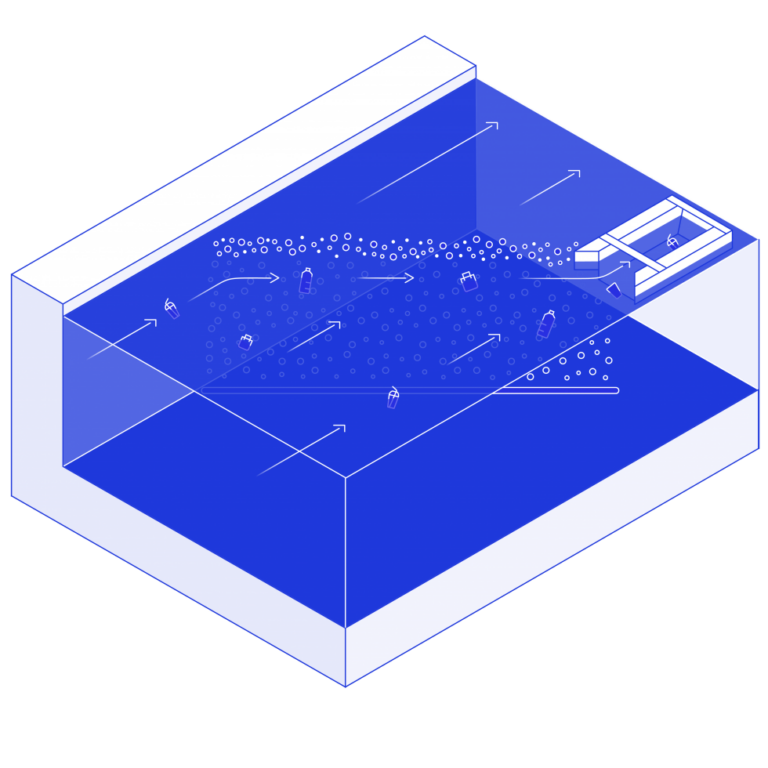

The Bubble Barrier prevents plastic pollution by creating a bubble screen within the waterway.

The Bubble Barrier prevents plastic pollution by creating a bubble screen within the waterway. This is achieved by placing the tube (with holes) along the bottom of the waterway and pumping air through a tube.

The amount of money needed for full implementation of a new Bubble Barrier highly depends on the local conditions (width, depth, flow velocity, etc). Correspondence with the Manufacturer in August 2020

Target SDGs

SDG 6: Clean Water and Sanitation

Target Users (Target Impact Group)

Public Sector Agencies

Distributors / Implementing Organizations

This product is implemented by the manufacturer.

Competitive Landscape

Direct competitors include Mr. Trash Wheel and Interceptor.

Regions

Worldwide

Manufacturing/Building Method

Intellectural Property Type

Patent

User Provision Model

Users can obtain the product by directly contacting the manufacturer.

Distributions to Date Status

As of August 2020, Bubble Barriers have been installed at a wastewater treatment plant in Wervershoof, New Holland and in Amsterdam, commissioned by the Regional Water Authority Amstel, Gooi and Vecht and the municipality of Amsterdam

User operation

Automated

Consumables

None

Power supply type

Electrical

Design Specifications

The Bubble Barrier works by using a tube with holes, which is placed on the bottom of a river. Pumping air through the tube creates a bubble curtain. The air bubbles force plastics in the water to the surface, making them accessible for removal. This concept is used in the oil industry, the dredging industry, and the Dutch lock system. By placing the bubble barrier diagonally to the flow of a river, the power of the river forces debris to the banks of the river, where it can be easily removed from the water. The Bubble Barrier also uses the natural current to guide the plastic to the local catchment system.

Additional positive side effects include 1.) increased oxygen levels within the water, which stimulate the ecosystem and prevent the growth of toxic blue algae, and 2.) absorption of sounds and waves meaning fish and shores experience less harm from the ship traffic.

Technical Support

Provided by the manufacturer.

Replacement Components

The manufacturer can be contacted regarding the replacement of any components such as the PVC tube or compressor.

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

The manufactured specified performance targets are as follows:

Vetted Performance Status

Initial concept testing took place in the flumes at Deltares in May 2017. A 200 m length Bubbles Barrier was subsequently tested at Kampen in the IJssel at the end of 2017. The 3-week investigation shows that that the Bubble Barrier works under all Dutch autumn weather conditions and that it catches 86% of all used test material on average.

Safety

No known safety hazards are related to this product. However, the manufacturer must be involved in its correct installation in a waterway.

Complementary Technical Systems

The manufacturer indicated they are always looking for creative uses for the plastic which has been removed, in order to create more awareness about waterway pollution.

Academic Research and References

Spaargaren, L., 2018, The Bubble Barrier, Delft University of Technology Master Thesis.

Compliance with regulations

It is understood that the Bubble Barrier is compliant with known regulations as the product does not require any changes in infrastructure or policies. Any potential issues arising from implementation in different countries will be addressed on a project basis with the relevant authorities.

Evaluation methods

The manufacturer cites laboratory testing to assess the product’s ability to block all types of materials under all weather conditions present during a Dutch November month catching 86% of all used test material on average.

Other Information

The great bubble barrier - A smart solution to plastic pollution

Agriculture

November 24, 2023

Implemented by

Hadleigh Health Technologies, and Rice 360

Agriculture

August 8, 2024

Implemented by

Patrick Kiruki, Banza Sanitation

Agriculture

January 10, 2024

Implemented by

Dr. David Manz, University of Calgary

Agriculture

August 13, 2024

Implemented by

The Africa Trust

Agriculture

August 14, 2024

Implemented by

Envirosan

Agriculture

January 8, 2024

Implemented by

Healing Waters International

Agriculture

January 16, 2024

Implemented by

George Greene III, PE, PhD

Agriculture

January 3, 2024

Implemented by

Department of Civil and Environmental Engineering, University of Virginia

Agriculture

June 24, 2024

Implemented by

WellDone

Agriculture

December 7, 2023

Implemented by

Nazava

Have thoughts on how we can improve?

Give Us Feedback