Agriculture

February 1, 2024

Iketsetse Single Stroke Maize Sheller

Read SolutionImplemented by

Elliot Litsebe Tsiame

Updated on February 21, 2024

·Created on September 15, 2020

The Containerized Maize Mill is a mobile system for the storage and milling of grains.

The Containerized Maize Mill is a storage and milling system for grains. It is made of two containers stacked vertically. One side of the system is designed for the storage of grains under silo conditions with aeration and fumigation systems and bulk handling. The other side of the system houses the mill.

Target SDGs

SDG 2: Zero Hunger

Market Suggested Retail Price

$65,000.00

Market Suggested Retail Price (Secondary Currency)

1,100,000 ZAR

Target Users (Target Impact Group)

Small and Medium-sized Enterprises

Distributors / Implementing Organizations

The product is available at ABC Hansen

Regions

Africa

Manufacturing/Building Method

The Containerized Maize Mill is made using two containers stacked vertically. These two containers houses the system for the storage and milling of grains.

Intellectural Property Type

Trademark

User Provision Model

Users can buy the Containerized Maize Mill directly from ABC Hansen. However, the containerized mills cannot be exported via sea-freight since the container is altered.

Distributions to Date Status

~ 10 units

Feedstock types

Maize, wheat, millet, sorghum, teff and other grains

Feedstock rate (kg/hr)

500 – 1000

Power source

Electricity

Energy requirement (W)

60 kWInterview with representative

Portable or stationary

Portable

Design Specifications

The Containerized Maize Mill is made from two vertically-stacked containers. The product is built to be able to hold about 20 to 30 tons of grain at a time under silo conditions with aeration and fumigation systems and bulk handling in one portion. For storage, grain is dumped either in bulk from trucks or from bags into a triangular reception bin and is conveyed by means of a bucket elevator or vertical screw conveyor to the top of the stacked silos and from there conveyed by horizontal auger to the storage section.

The milling section is in the other portion of the containerized mill. To mill, stored grain is conveyed by horizontal auger to the vertical auger or bucket elevator to the top of the stacked containers and by horizontal conveyor past the storage section into the milling section’s grain cleaner where the small grains are separated from the good quality grain and then dampened or otherwise processed. For maize and wheat, a first-in-first-out bin is used for the dampening and conditioning.

Technical Support

ABC Hansen offers technical support and training for users

Replacement Components

Unknown

Lifecycle

10-15 years

Manufacturer Specified Performance Parameters

The Containerized Maize Mill is designed to allow for both storage and milling of grains.

Vetted Performance Status

None

Safety

There are no known safety hazards linked with the use of this product

Complementary Technical Systems

The Containerized Maize Mill requires electricity from a 3-phase power source to operate. Alternatively, a diesel generator of 25 KVA to 100 KVA power may be required to power the mill where there is no access to electricity.

Academic Research and References

Sharma, K., Kothari, S., Panwar, N. L., & Rathore, N., 2020, Design and Development of solar energy powered maize milling machine. International Journal of Ambient Energy, pp 1-6.

Compliance with regulations

The mill is CE CompliantInterview with representative

Other Information

Agriculture

February 1, 2024

Implemented by

Elliot Litsebe Tsiame

Agriculture

August 21, 2024

Implemented by

Marius Rossouw design engineer Aflastop

Agriculture

January 12, 2024

Implemented by

VIP

Agriculture

August 23, 2024

Implemented by

Mayapedal

Agriculture

September 18, 2024

Implemented by

Agsol

Agriculture

September 4, 2024

Implemented by

International Development Enterprises

Agriculture

January 31, 2024

Implemented by

KickStart International

Agriculture

January 31, 2024

Agriculture

January 20, 2024

Implemented by

SunCulture

Agriculture

May 24, 2024

Implemented by

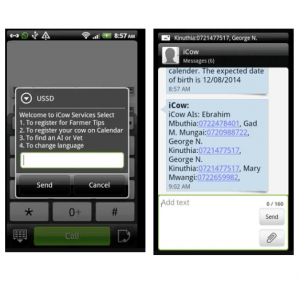

iCow

Have thoughts on how we can improve?

Give Us Feedback