Agriculture

August 4, 2024

Partners for Development Taxi Service

Read SolutionImplemented by

Partners for Development Taxi Service

Updated on March 11, 2024

·Created on August 6, 2016

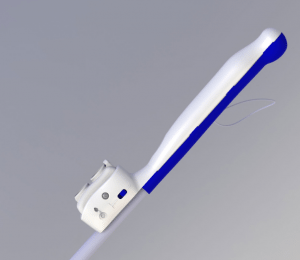

Coolar is a vaccine refrigerator powered by heat instead of electricity

The Coolar system is a medical refrigerator that uses warm water generated through solar energy to provide an affordable, durable, and sustainable solution for vaccine, medicine, and food storage in regions with unreliable or expensive electricity. Coolar is currently in a prototype stage.

Target SDGs

SDG 3: Good Health and Well-Being

Target Users (Target Impact Group)

Public Sector Agencies, NGOs

Distributors / Implementing Organizations

This product is a prototype as of June 2017 and no distributors or implementors have been established, although Coolar is in the process of teaming up with industry partners and developmental organizations like Doctor's Without Borders to bring the solution to market. Coolar is supported by Bayer cares foundation, Expo 2020 Dubai UAE and others

Competitive Landscape

Direct competitors include Sure Chill Vaccine Refrigerator BLF100 DC.

Agriculture

August 4, 2024

Implemented by

Partners for Development Taxi Service

Agriculture

November 30, 2024

Implemented by

Pivot Works Ltd.

Agriculture

February 5, 2024

Implemented by

Circ MedTech

Agriculture

February 5, 2024

Implemented by

PlenOptika

Agriculture

February 5, 2024

Implemented by

SmartCane TM

Agriculture

January 31, 2024

Implemented by

SolSuffit

Agriculture

February 26, 2024

Implemented by

Foldscope Instruments

Agriculture

March 8, 2024

Implemented by

NRSRelief

Agriculture

February 6, 2024

Implemented by

Toray Industries Inc.

Agriculture

June 22, 2024

Implemented by

Wello

Have thoughts on how we can improve?

Give Us Feedback