Agriculture

January 11, 2024

Caminos de Agua Ceramic filters

Read SolutionImplemented by

Caminos de Agua

Updated on January 8, 2024

·Created on August 27, 2015

This product utilizes an electrolysis process to absorb and reduce arsenic concentration in water.

ECAR (ElectroChemical Arsenic Remediation) works using low-voltage electricity to dissolve an iron electrode, creating iron oxide (rust). The rust particles adsorb arsenic, creating larger particles, which are then filtered out of solution. The process converts arsenite into arsenate, a less toxic compound that can be more efficiently removed from water.

Target SDGs

SDG 6: Clean Water and Sanitation

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$0.03

Target Users (Target Impact Group)

Community

Distributors / Implementing Organizations

Licensed by Luminous Water Technologies; Luminous Water Technologies and UC Berkeley are working together to develop an effective model for ECAR.

Competitive Landscape

Direct competitors include Kanchan Arsenic Filter (KAF).

Countries

United States

Manufacturing/Building Method

The ECAR is a conventional aqueous electrolysis process with two submerged electrodes, anode and cathode.

Intellectural Property Type

Select Type

User Provision Model

The group behind ECAR aims to create a fully automated water treatment system that takes groundwater through pumping, and purifies it using ECAR. This model would be at the community-level, maintained by locally hired technicians, and supported through educational programming. Each system will be profitable due to the low cost of materials, financially sustainable, and enable community-wide quality control and waste removal.

Distributions to Date Status

Only field trials of prototypes have been carried out.

Description of the combined methods

Electrolysis

Manufacturer-specified water treatment rate (L/hr)

500 L/hr

Bacteria reduction

Unknown

Virus reduction

Unknown

Protozoa reduction

Unknown

Heavy metals and/or arsenic reduction

Yes, arsenic reduction to <0.01 mg/L

Maximum recommended influent turbidity level (NTU)

Unknown

Effluent turbidity levels (NTU)

Unknown

Safe water storage capacity (L)

Unknown

Manufacturer-specified lifetime volume (L)

7,300,000 L

Consumables

Electricity

Design Specifications

The ECAR is a conventional aqueous electrolysis process with two submerged electrodes, anode and cathode. During the electrolysis process, arsenic-III is oxidized at the anode to arsenic-V and simultaneously, iron-III-hydroxide as a coagulant, is generated. The iron-III-hydroxide flocs are active adsorbents for arsenic-V. Arsenic loaded iron flocs are removed by settling and/or filtration.

Technical Support

The licensee provides support. During the first several implementations, researchers will aid in the process until licensee is capable. Interview with representative

Replacement Components

All parts are locally purchased in India. Interview with representative

Lifecycle

Safe for US landfill disposal; produces 300 g/person/year of waste; A method for incorporating arsenic-laden waste into concrete is being used in China to dispose of arsenic without risk of leaching.

Manufacturer Specified Performance Parameters

Remove arsenic to meet WHO guidelines for arsenic in drinking water of 0.01 mg/L.

Vetted Performance Status

Preliminary testing found that groundwater containing 250 µg/l of Arsenic was consistently reduced to below the WHO maximum contaminant level (MCL) of 10 µg/l over several months. Trivalent Arsenite is oxidized to pentavalent arsenate, allowing it to be adsorbed more strongly. ElectroChemical Arsenic Removal (ECAR) for Rural Bangladesh – Merging Technology with Sustainable Implementation found the ECAR could reduce arsenic levels > 500 ppb to less than 10 ppb (0.01 mg/L) in synthetic and real Bangladesh groundwater samples.

Safety

ECAR produces arsenic-laden iron sludge that must be disposed of appropriately. The technology uses low voltage electricity. ECAR does not require handling of highly acidic or corrosive chemicals for regeneration or cleaning.

Complementary Technical Systems

Coupling of ECAR with a groundwater pump improves value, can reduce total costs, and reduces risk of additional contamination of water. Biological contamination can be removed with the addition of chlorination or UV disinfection. In conjunction with ECAR, use of safe-storage containers is required.

Academic Research and References

“Locally Affordable Arsenic Remediation for Rural South Asia using Electrocoagulation” Addy et al.

“Structure of Fe(III) precipitates generated by the electrolytic dissolution of Fe(0) in the presence of groundwater ions” Genuchten et al.

“Electro-chemical arsenic remediation: Field trials in West Bengal” Amrose et al.

“Locally affordable and scalable arsenic remediation for South Asia using ECAR” Amrose et al.

“Arsenic removal from groundwater using iron electrocoagulation: effect of charge dosage rate” Amrose et al.

“Addressing Arsenic Poisoning in South Asia” Gadgil et al.

“Modeling As(III) oxidation and removal with iron electrocoagulation in groundwater” Li et al.

“Removing Arsenic from Synthetic Groundwater with Iron Electrocoagulation- An Fe and As K-edge EXAFS study” Genuchten et al.

“A novel technology to remove arsenic from drinking water for Bangladesh tubewells” Gadgil et al.

“Electrochemical arsenic remediation for rural Bangladesh” Addy et al.

“ElectroChemical Arsenic Removal (ECAR) for Rural Bangladesh – Merging Technology with Implementation” Addy et al.

Motivation, A. G. Electrochemical Arsenic Remediation (ECAR), Lbl.gov. Available at: https://www.werri.lbl.gov/wp-content/uploads/sites/18/2018/11/Advanced-Boden_WERRI_ecar_1Page.pdf

Indian company licenses Berkeley Lab invention for arsenic-free water – Berkeley Lab (2014) Berkeley Lab News Center. Lawrence Berkeley National Laboratory. Available at: https://newscenter.lbl.gov/2014/03/05/indian-company-licenses-berkeley-lab-invention-for-arsenic-free-water/

Kanchan, A. F. et al. A SIMPLE SOLUTION FOR ARSENIC PROBLEM, Mit.edu. Available at: http://web.mit.edu/watsan/Docs/Other%20Documents/KAF/KAF%20booklet%20final%20Jun05.pdf

Goal 6 Sdgs.un.org. Available at: https://sdgs.un.org/goals/goal6

Susan Addy: Electrochemical Arsenic Remediation (2018) LAUNCH. Available at: http://www.launch.org/innovators/susan-addy/

Project Equal Welcome to the official website of Jadavpur University, Edu.in. Available at: http://www.jaduniv.edu.in/

Gadgil, A. and Berkeley, U. C. Answers to frequently asked questions (FAQs) about ElectroChemical arsenic remediation (ECAR) http://arsenic.lbl.gov, Berkeley.edu. Available at: http://gadgillab.berkeley.edu/wp-content/uploads/2012/07/ECAR_FAQ_v15.pdf

Delaire, C. (2013) Electro-Chemical Arsenic Remediation for south Asia. Youtube. Available at: https://www.youtube.com/watch?v=HoNzkpgntOk

Compliance with regulations

Sludge produced passes US EPA standard TCLP test.

Evaluation methods

Field and laboratory testing (see Academic Research above).

Other Information

Youtube Video: Electro-Chemical Arsenic Remediation for South Asia

Agriculture

January 11, 2024

Implemented by

Caminos de Agua

Agriculture

January 17, 2024

Implemented by

Aquagenx

Agriculture

September 23, 2023

Implemented by

Innovations for Poverty Action

Agriculture

August 14, 2024

Implemented by

Esther Mwangi, EsVendo

Agriculture

December 29, 2023

Implemented by

LifeStraw

Agriculture

December 29, 2023

Implemented by

Sawyer

Agriculture

June 26, 2024

Implemented by

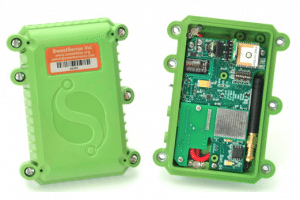

SweetSense Inc

Agriculture

January 3, 2024

Implemented by

Antenna Technologies

Agriculture

January 3, 2024

Implemented by

Fred Barrett and Dale Andreatta

Agriculture

January 19, 2024

Implemented by

SaniTap

Have thoughts on how we can improve?

Give Us Feedback