Agriculture

January 28, 2024

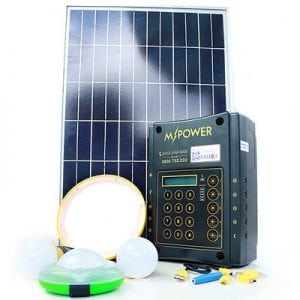

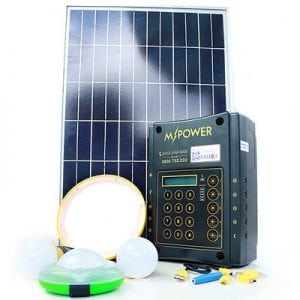

Off-Grid Electric Solar Home System

Read SolutionImplemented by

Off-Grid Electric

Updated on June 22, 2024

·Created on September 2, 2020

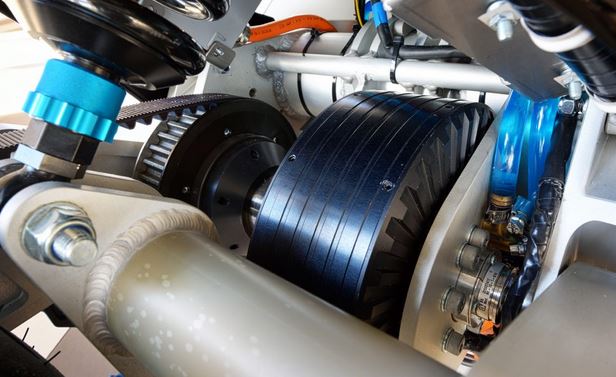

Emrax E-motors is an electric propulsion system manufacturer providing engine solutions for the aviation, automotive, and maritime industries.

The Emrax Electric Motor is an axial flux motor available with different battery capacities depending on the intended usage, manufactured by Emrax Electric. The motors are stackable to increase the available power. The manufacturer offers the possibility to build customized motor controller packages depending on the need.

Price depends on the configuration, a quote is needed for an estimate.

Target SDGs

SDG 7: Affordable and Clean Energy

Target Users (Target Impact Group)

Household, Community, Public Sector Agencies

Distributors / Implementing Organizations

Emrax d.o.o

Regions

Worldwide

Manufacturing/Building Method

The electric motors are manufactured at Emrax facilities in Slovenia.

Intellectural Property Type

Trademark

User Provision Model

The potential user establishes a quote for a specific configuration and sends it to the manufacturer. The user then receives a reply with the expenses and can then order the engine. The manufacturer will then ship the product from Slovenia.

Distributions to Date Status

Unknown

Capacity

N/A

Gear Ratio

N/A

Maximum load capacity (kg)

N/A

Design Specifications

Emrax motor has the following features:

Technical Support

Provided by the manufacturer via contact by email

Replacement Components

Bearings, internal discs, and jacks

Lifecycle

Lifetime of the motor is the same as the lifetime of the bearing

Manufacturer Specified Performance Parameters

– Customized in shortest time

– Best in class power density (up to 10 kw/kg)

– Best in class efficiency (up to 98%)

– Compact and durable design

– Stacking option

Vetted Performance Status

In February 2014 thermal tests were performed. The motor was exposed to shock tests from -40°C to +160°C for 17 days (24h/day). The test results were satisfactory. In addition, customer feedback is continuously gathered.

Safety

Mixing up the polarity of the battery or a short circuit leads to a destruction of the drive and represents an acute fire hazard and danger of life.

Complementary Technical Systems

One-man rigging aid

Academic Research and References

Allison, M. , Bidwell, B., Hopson, S., Smith, J., Streegan, C. and Villa, D., 2013, Formula Electric: Powertrain, Bachelor thesis, Department of Mechanical Engineering, Santa Clara University

Compliance with regulations

EMC certificate (E26)–electromagnetic field testing: the motor complies with essential protection requirements of EMC Directive 2014/30/EU. EMRAX approval number is: E26 10 R 05 1160.

EMRAX is in process of obtaining ISO 9001:2015 certificate.

EMRAX is in process of obtaining European Union Aviation Safety Agency (EASA) certification for EMRAX 268 motor

Evaluation methods

Thermal tests, Schock Tests

Other Information

More information on the product is included in Manual for EMRAX Motors/Generators

Agriculture

January 28, 2024

Implemented by

Off-Grid Electric

Agriculture

June 22, 2024

Implemented by

SunCycles

Agriculture

January 27, 2024

Implemented by

Sunspot PV LLC

Agriculture

June 27, 2024

Implemented by

Bodawerk International Ltd

Agriculture

June 20, 2024

Implemented by

Electric Vehicle Association of Thailand (EVAT)

Agriculture

June 23, 2024

Implemented by

Motivo Engineering

Agriculture

January 20, 2024

Implemented by

Adventist Development and Relief Agency (ADRA)

Agriculture

December 31, 2023

Implemented by

Potential Energy

Agriculture

December 27, 2023

Implemented by

Nippon Basic Co. Ltd.

Agriculture

November 30, 2024

Implemented by

Deciwatt

Have thoughts on how we can improve?

Give Us Feedback