Agriculture

December 18, 2024

Breezergy Micro Wind Turbine

Read SolutionImplemented by

SkyWind Energy GmbH

Updated on December 22, 2023

·Created on October 5, 2018

The Micro Compound Lever Briquette Press is a wood biomass fuel briquette press designed by Engineers Without Borders (EWB) - Greater Cincinnati Professionals.

The Micro Compound Lever Briquette Press is a biomass fuel briquette press, which compresses biomass into usable fuel. The structure is made of wood and weights up to 12 kgs. It has a compression range from 300 mm to 190 mm and can make square or traditional round briquettes with or without holes at a rate of 12 units every 10 minutes from biomass, biochar or charcoal fines. It has two possible configurations: Notch and Brace versions, which can both be built using power or hand tools.

Target SDGs

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$18.00

Target Users (Target Impact Group)

Household, Community

Distributors / Implementing Organizations

Self-constructed by the end users.

Regions

Worldwide

Manufacturing/Building Method

Following the construction manual, the briquette press can be constructed by users with minimal skill level using either power tools or hand tools.

Intellectural Property Type

Open-source

User Provision Model

Users can build the product following the Micro Compound Lever Press construction manual.

Distributions to Date Status

The press has been built and used both in many developing countries and by many U.S. organizations as part of gardening projects. Some examples of the use of this product can be found in the Philippines and in Tokyo, Japan. Interview with representative

Material composition

Briquettes made from biomass and charcoal

Higher heating value (MJ/kg)

Unknown

Types of primary pollutants

Unknown

Design Specifications

Both versions, Brace and Notch designs, have a total of 10 parts (two front and two rear leg, two feet, two arms and a level arm, two base beam, a handle, two beam sides and a brace) mainly made by same section pieces of wood (38 x 89 mm) and with different lengths. Pieces are joined with bolts and nuts, resulting in a lightweight press structure of 12 kgs. Softwood can be used and hardwood is recommended for the high-pressure level arm.

Technical Support

Full instructions and photographs on how to build the press are given in the construction manual. For further details contact the designers.

Replacement Components

Lifecycle

Over 10 years. Interview with representative

Manufacturer Specified Performance Parameters

EWB-Cincinnati's main goal is to have a flexible press design. The design allows the use of local materials and does not require specific features that might not be available in various countries. The designers aimed to have good throughput and a high amount of pressure for good compression of the briquette. The press exceeded the performance targets for pressure (see the “Vetted Performance” below). Additionally, ease of use was enhanced by offering several different types of molds to form the briquette. Interview with representative

Vetted Performance Status

With 32 kg of force on the handle, 1,800 kg of force is transmitted to the briquette located 100 mm from the end pivot point. Based on a typical biomass pressing requirement of 65 kg/in2 of force, the required pressures are 400 kg for a 75 mm briquette with a 25 mm hole, 1,040 kg for a 100 mm square briquette with no hole, 1,800 kg for a 150 mm diameter briquette without the hole. The press can easily exceed those force requirements.

Safety

Potential hazards include cuts and accidents when cutting the wood pieces for the structure. During periods of non-use, EWB recommends storing the product in a dry and sun free location.

Complementary Technical Systems

EWB provides information about the self-construction of several other designs and products, such as: various biomass briquettes molds suitable for the press, a dry biomass grinder thrasher, wet-dry biomass choppers/cutters, as well as a rotatable and portable DIY biomass composer.

Academic Research and References

All documents for the Micro Compound Lever Briquette Press can be found on the EWB-Cincinnati webpage, however there is no specific academic research on this design. General information on biomass briquetting can be found in the following article:

Grover, P.D., and Mishra, S.K., 1996, Biomass briquetting: technology and practices, FAO, Regional wood energy development programme in Asia, Field document No. 46.

Hite , Lee , Zan Smith, and Ron Gorley. 2021. Review of How to Build a Micro Compound Lever Briquette Press. Cincinnati, OH, USA: Engineers without Borders – USA, Greater Cincinnati Professional Chapter .

Philippines. 2011. Biomass Briquette Stoves. March 31, 2011.

Saw Dust Reuse | ????? | Genereight. n.d. www.genereight.com.

Compliance with regulations

N/A

Evaluation methods

The improved first prototype was tested by EWB local group and several suggestions that could improve the performance of the product were accepted and implemented. EWB took the design to several villages in Rwanda where the press was built and used. EWB-Cincinnati followed the implementation of this technology with personal visits up for a period of five years. Communities in Rwanda continued to have success using the press. Interview with representative

Other Information

Video of demonstration on how to build and use the press.

Agriculture

December 18, 2024

Implemented by

SkyWind Energy GmbH

Agriculture

December 26, 2023

Implemented by

Ecofrost Technologies, a subsidiary of Ecozen.

Agriculture

December 2, 2024

Implemented by

Asian Phoenix Resources Ltd.

Agriculture

December 2, 2024

Implemented by

NTN Global

Agriculture

January 5, 2024

Implemented by

MeraGao Power

Agriculture

September 10, 2024

Implemented by

Alvan Blanch

Agriculture

February 1, 2024

Implemented by

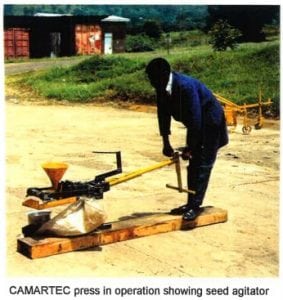

Centre for Agricultural Mechanization and Rural Technology (CAMARTEC)

Agriculture

February 1, 2024

Implemented by

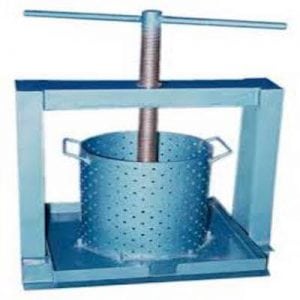

Piteba

Agriculture

September 10, 2024

Implemented by

Tinytech Plants

Agriculture

March 4, 2024

Implemented by

Makiga Engineering Services LTD

Have thoughts on how we can improve?

Give Us Feedback