Agriculture

February 29, 2024

CARC Hybrid Wheelchair

Read SolutionImplemented by

BRAC University

Updated on February 29, 2024

·Created on June 7, 2014

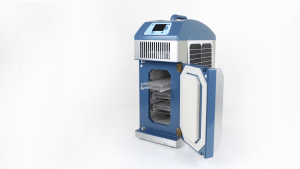

GEN_1 Design Wheelchair is a durable wheelchair designed for use in rugged terrain.

The GEN_1 Design is a one-size-fits-all multipurpose wheelchair designed for use in rugged terrain. It provides basic motility to a wide range of users and is generally recommended for those who do not need adjustments to the wheelchair to aid postural support. The GEN_1 Design is designed and manufactured under Free Wheelchair Mission (FWM).

Target SDGs

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$80.00

Target Users (Target Impact Group)

Household

Distributors / Implementing Organizations

Free Wheelchair Mission works in collaboration with other charitable organizations acting as local distribution partners.

Competitive Landscape

Direct competitors include Motivation Rough Terrain Wheelchair and Rough Rider Wheelchair.

Regions

Africa, Central Asia, East Asia and Pacific, Latin America, South Asia

Manufacturing/Building Method

Wheelchair kits are mass produced, shipped from the factory by the container and assembled by pre-approved distribution partners in recipient countries. Each container contains 550 wheelchairs ready for assembly with 50 toolkits (11 wheelchairs can be assembled with one toolkit). Assembly takes 15 minutes and all tools required are provided in the container.

Intellectural Property Type

Open-source

User Provision Model

Local distribution partners are responsible for locating qualified beneficiaries. Over 1,000,000 wheelchairs have been distributed in 93 countries around the world (as of July 2020). Charitable organizations around the world may request a minimum order of 550 wheelchairs, which they must then assemble and distribute in their local region.

Distributions to Date Status

Over 1,000,000 wheelchairs have been distributed in 93 countries around the world as of July 2020.

Maximum rider load (kg)

90

Seat widths (min-max, cm)

< 51cm

Seat depths (min-max, cm)

Unknown

Adjustable seat (yes/no)

No

Frame type (folding/rigid)

Rigid

Frame type (material)

Steel frame following the contours of the polypropylene resin chair

Seat angles (degrees):

Fixed. Angle unknown.

Footrest heights (min-max)

Footrest height can be adjusted to four different leg lengths giving a total range of 31 cm

Repairable with universal components (yes/no)

Yes

Chair weight (kg)

15.8kg

Fatigue tested (yes/no)

Yes

Fatigue test results (cycles)

200,000 cycles

Design Specifications

GEN_1 specifications:

- 35 lb (16 kg)

- conventional 4-wheel design

- 8” x 1” front casters

- 24” x 1.95” mountain bike rear tires

- brakes on both rear wheels

- rigid, non-folding steel frame

- polypropylene resin chair (virgin resin) + UV stabilizer

- adjustable leg-length footrest

- a 3 cm thick urethane foam cushion

- a hand air pump and patch kit fixed to the frame

- a 5 strap adjustable harness for children and adults as needed

- nylon insert stay-tight nuts

- Approximate resin chair dimensions (based on commercially available chair): 31""h x 20""w x 22""d

- Rated to hold up to 90 kg (198 lbs)

Technical Support

Assembly guide is available online.

FWM provides training videos for the distribution partners to watch: assembly video and care and maintenance video.

Distribution partners are trained by FWM through the "Leading Partner Program" to properly prescribe and fit wheelchairs as well as train recipients how to better care for themselves and their wheelchair.

Recipients all receive a manual with their wheelchair that covers proper use and maintenance. A training video is also shown to recipients (when a video cannot be shown, a live demonstration is given).

Replacement Components

FWM promotes that their wheelchair was designed to be repaired by replacement parts that are readily available around the world. Manuals are distributed with each chair that inform recipients that they can contact the distributing partner for repair assistance.

In a report FWM provided USAID (2010) there is data from a survey distributed to recipients of FWM wheelchairs that touched upon repair and support issues.

Lifecycle

No disposal protocol information readily available. Designed to last 3-5 years.

Manufacturer Specified Performance Parameters

Functional on rough terrain; easily repairable; composed of readily available components for simple repair around the world; affordable in developing country contexts.

Vetted Performance Status

Dr. Susan Shore's field study, which surveyed recipients of FWM wheelchairs in India and Peru found: 28% of FWM recipients reported a repair at some time during use (average 18 months); 19.7% reported tire problems; most common maintenance problem reported was with the wheels (6.4% front, 13.3% back) including flat tires or dificulty with the valves; 2.7% reported problems with the resin chair; 62.2% of recipients were able to use the chair independently for mobility (all others were transported in the chair by family members or friends); 6.9% reported using their chair less than 1 hour/day, 46.3% used it 1–4 hours/day, and 46.8% used their chair more than 4 hours/day, 11.7% reported using their chair more than 8 hours/day.

Safety

GEN_1 version of FWM wheelchair is one size and thus does not allow for individual fitting to accommodate children or individuals with varying disabilities. A wheelchair that is not properly fit to the needs of an individual user can result in discomfort or injury (such as scoliosis or pressure sores) due to insufficient support or improper cushioning. There is also a risk of tipping while using a wheelchair.

Complementary Technical Systems

FMC has two other upgraded version GEN2 and GEN3 on their website.

Academic Research and References

Shore SL. Use of an economical wheelchair in India and Peru: impact on health and function. Med Sci Monit. 2008;14(12):PH71-PH79.

Shore S. The long-term impact of wheelchair delivery on the lives of people with disabilities in three countries of the world. Afr J Disabil. 2017;6:344. Published 2017 Sep 8. doi:10.4102/ajod.v6i0.344

Guidelines on the Provision of Manual Wheelchairs in Less Resourced Settings. Geneva: World Health Organization; 2008. 2, DESIGN AND PRODUCTION. Available from: https://www.ncbi.nlm.nih.gov/books/NBK143784/

Shore S., Kovic M., THE COMPARISON OF HEALTH AND FUNCTION OUTCOMES FOLLOWING USE OF A DEPOT STYLE WHEELCHAIR VERSUS ONE WITH A CUSTOMIZED FIT, RESNA Annual Conference, 2014.

Free Wheelchair Mission. “Distribution Partners.” 2020.

Free Wheelchair Mission. “Ordering Wheelchairs.” 2020.

Free Wheelchair Mission. “Where We Work.” 2020.

Free Wheelchair Mission. “Specifications Guide.” 2020.

Free Wheelchair Mission. “How to Assemble a Wheelchair.” YouTube, 2009

Free Wheelchair Mission. “Wheelchair user.” YouTube, 2009

Free Wheelchair Mission. “Assembly of the Free Wheelchair Mission GEN 1.” 2020.

USAID. “USAID’s Provision of Wheelchairs in Developing Countries Project.” Free Wheelchair Mission Final Report, 2010.

Compliance with regulations

ISO 7176-1:2014: Wheelchairs — Part 1: Determination of static stability

ISO 7176-3:2003 Wheelchairs — Part 3: Determination of effectiveness of brakes

ISO 7176-5:2008 Wheelchairs — Part 5: Determination of dimensions, mass and manoeuvring space

ISO 7176-7:1998 Wheelchairs — Part 7: Measurement of seating and wheel dimensions

ISO 7176-8:2014 Wheelchairs — Part 8: Requirements and test methods for static, impact and fatigue strengths

ISO 7176-15:1996 Wheelchairs — Part 15: Requirements for information disclosure, documentation and labelling

ISO 7176-16:2012 Wheelchairs — Part 16: Resistance to ignition of postural support devices

ASTM: A53 PIPE SPECIFICATIONS

Evaluation methods

The FWM GEN_1 wheelchair is subjected to the International Organization of Standards (ISO) double-drum test. It uses 100 kilograms of weight for 200,000 cycles on an ISO standard double drum tester for a month. The test is estimated to simulate the stress a wheelchair would be subjected to over five years of use in a developing country.

Other Information

FWM has won dozens of awards for their wheelchair distribution work.

Agriculture

February 29, 2024

Implemented by

BRAC University

Agriculture

February 29, 2024

Implemented by

Motivation

Agriculture

February 29, 2024

Implemented by

Whirlwind Wheelchair International

Agriculture

February 20, 2024

Implemented by

Stone Cold Systems

Agriculture

February 19, 2024

Implemented by

Save the Children

Agriculture

February 21, 2024

Implemented by

Federal Emergency Management Agency (FEMA)

Agriculture

February 21, 2024

Implemented by

World Bank SKAT

Agriculture

January 2, 2024

Implemented by

Uzima

Agriculture

February 21, 2024

Implemented by

Flexmo

Agriculture

June 6, 2024

Implemented by

Hello Doctor

Have thoughts on how we can improve?

Give Us Feedback