Agriculture

December 16, 2023

G2E Biomass Gasification Plant

Read SolutionImplemented by

Green to Energy (G2E)

Updated on December 16, 2023

·Created on June 5, 2014

Based in India, the U.S. and Tanzania, HPS sells its proprietary gasification products and maintenance services to agro-processing plants.

The Husk Power Systems technology is a 25 – 100 kW biomass gasifier that converts residual biomass to energy through pyrolysis and combustion of volatile gases. Husk Power Systems targets the agro-processing communities in the state of Bihar, India who process significant quantities of rice.

Husk Power Systems is located in Patna, Bihar, India. A video about the company’s business.

Target SDGs

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$30,000.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

Husk Power Systems in partnership with several organizations.

Competitive Landscape

Direct competitors include SimGas GesiShamba, NETPRO biomass plant, and TINYTECH Portable Biogas Plant.

Regions

North America

Countries

India, Tanzania

Manufacturing/Building Method

Manufactured on per demand basis.

Intellectural Property Type

Patent

User Provision Model

Directly from the company or partner organizations.

Distributions to Date Status

For August 2018 and in five years time, the company has lighted 12,000 households, a total of 35 villages and within 75 plants constructed, saving 15,000 CO2 tons/year. They aim to raise the power generation to 30 MW by 2021.

Power rating (W or kW)

32 kW (rated capacity of 25 – 100 kW)

Available energy type (mechanical, thermal, electrical)

Electrical

Description of biomass source(s)

Rice husk or other agricultural waste without any processing or conversion into briquettes.

Biomass input requirements (kg per hour)

50 kg (110 lb) of husks per hour

Combustor type

Gasifier

Biomass conversion efficiency (%)

20

Particulate matter and CO emissions (ppm)

Unknown

Design Specifications

Design and Components:

• Fuel: Rice Husk or other agricultural waste

• Water cooled

Each unit is composed of:

• Downward draft rice husk gasifier (40-50 kg husk/hr r gas)

• Venturi/gas cleaning cum cooling system

• Water seal

• Three stage gas filters including charcoal filter, husk/sawdust filter, and fabric filter

• Spark ignition engine and generator unit

• 2 lead acid batteries for cranking the engine

The facility also includes husk storage area, water tank, hand operated water pump, char and tar-water settling tanks, char/tar storage area and water recycling pumps.

The electricity generated is 3-phase – 415 Volts at the bus bar in the plant, and each phase being 230 Volts. Each of the 3-phases at 230 Volts constitutes one distribution circuit. The distribution grid is comprised of single phase lines extended into various parts of the village from which connections that feed into each household are drawn. The distribution system is comprised of double sheath cables mounted on bamboo poles and does not use transformers. Hence, the grid is not extended beyond 1.5 km to ensure at least 190 Volt at the farthest point on the grid.

Technical Support

A key factor in the success of HPS is its emphasis on local staff recruitment and training in strict operating procedures at the village level. HPS is also planning to build a training centre (HPS University), and also provide some training by distance learning.

Replacement Components

Components can likely be outsourced directly through HPS.

Lifecycle

Plant estimated lifetime is over 20 years.

Manufacturer Specified Performance Parameters

Performance targets:

• 25-100 kW (usually 30W connected load at each household at 6 -7 hours of power consumption per day (2x15 watts CFLs & cellphone recharge))

• 32 kilowatts of electricity from 50 kilograms (110 lb) of husks per hour

• 400 households per each system installed

• 6 - 7 hours of power consumption per day (2 lights and phone charging)

• 56 BHP -1500 RPM

• Plots of size range from 185.8m2 to 464.5 m2

By 2022 HSK's mission in India is to have 400 sites to be commissioned with a power generation of 2.5 MW. In West Africa is to have 50 sites commisioned with 2.5 MW power generation and in Tanzania 150 commisioned sites with a total of 7.5 MW generation possibility.

Vetted Performance Status

Husk actively sells its proprietary gasification plants and maintenance services to agro-processing units like rice mills to help them reduce diesel consumption by up to 60%.

Safety

There are some potential dangers to running the biogas plant: noise, hazardous waste material disposal, etc. HPS takes special care to train all the workers to adhere to strict health and safety standards.

Complementary Technical Systems

Char byproduct is being used in incense making businesses for some villages, and silica is another by-product being monetized. By displacing kerosene and diesel solutions, each plant can be registered under Certified Emission Reductions (CER). HPS is also piloting programs to train local electricians to manufacture simple electronic products such as pre-paid meters or innovative products such as small refrigeration devices for rural micro-enterprises. H

Academic Research and References

Pokar, Kinjal, Chaurasia, Sushil and Maheshwari, Rajeev K (2012). Innovation at Bottom of Pyramid – Husk Power System: Electrifying Rural India (A Case Study). Ganpat University International Conference on Emerging Management Practices, Mehsana, Gujarat on 8th & 9th February 2013.

Manoj Sinha, (2011), Seeking an End to Energy Starvation (Innovations Case Narrative: Husk Power Systems). Innovations: Technology, Governance, Globalization, Summer 2011, Vol. 6, No. 3, Pages 71-83.

Samir Patela & Khanjan Mehtaa (2011).Life’s Principles as a Framework for Designing Successful Social Enterprises. Journal of Social Entrepreneurship, Volume 2, Issue 2, 2011. DOI:10.1080/19420676.2011.592407.

Bhattacharyya, S. C. (2014). Viability of off-grid electricity supply using rice husk: A case study from South Asia. Biomass and Bioenergy, 68, 44–54.

Google Scholar yielded several additional results.

CDM: Sustainable Development Programme of Rural Electrification by Husk Power Systems. n.d. cdm.unfccc.int.

Husk Power Systems: Generating Electricity from Waste for India’s Rural Poor. n.d. Knowledge at Wharton.

Institute for Financial Management and Research (IFMR), and Centre for Development Finance., 2010, Review of Empowering Villages: A Comparative Analysis of DESI Power and Husk Power Systems: Small-Scale Biomass Power Generators in India. India: Institute for Financial Management and Research (IFMR).

Performance Standard 1. n.d. IFC.

Performance Standard 2. n.d. IFC.

Husk Power. 2010. IFC Project Information and Data Portal.

Compliance with regulations

HPS is supported by the IFC - an investment of 350,000 USD in convertible quasi-equity (2010), and adheres to IFC's environmental and social standards: PS 1: Social and Environmental Assessment Management System, and PS 2: Labour and Working Conditions.

Evaluation methods

Case study comparing HPS and DESI powerplant using secondary data: concludes that both offer great solution for BOP small-scale village power demands (between 25 – 40kW total demand):

IFMR, Center for Development Finance, (2011). White paper case study – Rural Market Insight Brief: Empowering Villages. IFMR, Center for Development Finance, India.

Evaluation Methods: Age of the organization, Funding sources, Legal IncorporationOperation Area, Number of Plants, Average Time to set up a Plant, Collection Frequency and Timing, Technology Type, Supplier, Estimated Capital Cost, Cost per unit, Plant Size, CDM Revenues, Target Market, Revenue Collection

Other Information

Additional technologies installed are Pre?paid meters, smart monitoring /smart grid, dry exhaust gasifier and absorption chille. A Husk Power University is being set up for training as well as an international franchising system.

Agriculture

December 16, 2023

Implemented by

Green to Energy (G2E)

Agriculture

December 16, 2023

Implemented by

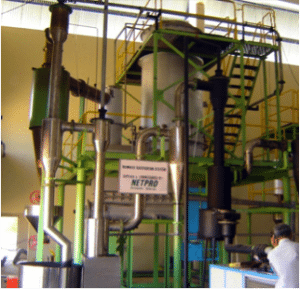

NETPRO Renewable Energy (India) Pvt Ltd

Agriculture

November 30, 2024

Agriculture

January 28, 2024

Implemented by

Appropriate Rural Technology Institute (ARTI)

Agriculture

January 21, 2024

Implemented by

Mali Biocarburant SA

Agriculture

December 18, 2024

Implemented by

Tinytech Plants

Agriculture

January 18, 2024

Implemented by

Agua Clara LLC

Agriculture

September 18, 2024

Implemented by

Alvan Blanch

Agriculture

November 13, 2024

Implemented by

All Power Labs

Agriculture

January 3, 2024

Implemented by

ovSolar

Have thoughts on how we can improve?

Give Us Feedback