Agriculture

March 7, 2024

Updated on September 19, 2024

·Created on October 13, 2020

The Fodder System is a hydroponic grow room designed to sprout grains for livestock.

The Hydroponics Kenya Fodder System is a temperature and humidity controlled growing room designed to sprout grains for livestock. Grain seeds are put into photo-chemically treated trays and sprayed with a nutrient-rich water solution. The system runs without electricity and utilizes a hydro-net and hydro-cloth to control temperature and humidity.

Target SDGs

SDG 2: Zero Hunger

SDG 1: No Poverty

Market Suggested Retail Price

$4,800.00

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

This product is sold and installed directly by the manufacturer.

Regions

Central Africa, East Africa

Countries

Kenya

Manufacturing/Building Method

The fodder systems are manufactured and installed on-site by Hydroponics Kenya.

Intellectural Property Type

Trade Secret

User Provision Model

Users can obtain a system by contacting the manufacturer directly.

Distributions to Date Status

700

Design Specifications

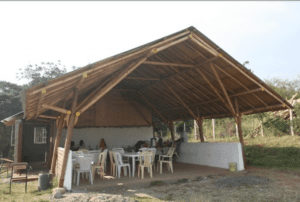

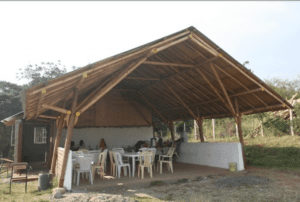

The system comes with a hydroponics housing unit, which is a custom built structure made of cloth, timber, and a concrete floor. There are wooden shelves in the housing unit which hold the hydroponics trays. The housing unit can be custom built to hold 70 to 1600 trays. The hydroponics trays are photo-chemically treated to prevent fungal growth, and the fodder is grown directly on the metal trays. The system also comes with liquid mineral nutrients which are sprayed on the fodder. Hydroponics Kenya can also provide barley seeds to customers.

Technical Support

Technical support, consulting, and training are provided by the manufacturer.

Replacement Components

Replaceable components include the hydroponics trays and the liquid mineral nutrients.

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

The manufacturer specifies that their fodder systems use a fraction of the water necessary for conventional farming, that their systems provide the same amount of fodder in a smaller land area, that their systems provide fodder all year regardless of weather conditions, that their systems require less manual labor, and that their fodder is highly nutritious.

Vetted Performance Status

Unknown

Safety

No known safety hazards are related to this product.

Complementary Technical Systems

Seed, potable water, and liquid mineral nutrients are required for this system.

Academic Research and References

Njima, P., 2016, An assessment of factors influencing production of hydroponics fodder among smallholder dairy farmers in Kiambu sub county, Kenya, Doctoral dissertation, University Of Nairobi, Kenya.

Strever, S.B., 2018, Understanding attitudes towards and perceptions of controlled environment agriculture among rural young adults in South Africa, Masters thesis, Ball State University, Muncie, IN

Compliance with regulations

Unknown

Agriculture

March 7, 2024

Agriculture

June 11, 2024

Implemented by

Agropestalert

Agriculture

May 24, 2024

Implemented by

Esoko

Agriculture

August 20, 2024

Implemented by

Technology for Tomorrow (T4T) Africa

Agriculture

June 23, 2024

Implemented by

Motivo Engineering

Agriculture

January 6, 2025

Implemented by

Microsoft

Agriculture

August 21, 2024

Implemented by

Marius Rossouw design engineer Aflastop

Agriculture

February 12, 2024

Implemented by

Naireeta Services

Agriculture

August 23, 2024

Implemented by

FOPO

Agriculture

September 19, 2024

Implemented by

Penn State HESE

Have thoughts on how we can improve?

Give Us Feedback

Great, Can this be used on a large scale application incorporated into an aquaponic system or does it function independently as an isolated system.