Agriculture

January 10, 2024

Hydraid® BioSand Filter

Read SolutionImplemented by

NativeEnergy

Updated on January 10, 2024

·Created on August 27, 2015

Ideas at Work (IaW) distributes Biosand Filters in Cambodia as an effective household water treatment system.

Ideas at Work (IaW) Round Biosand Filter is a product for providing improved quality water to rural communities in Cambodia.

This product is discontinued and no longer in production.

Target SDGs

SDG 6: Clean Water and Sanitation

SDG 3: Good Health and Well-Being

Target Users (Target Impact Group)

Household, Community

Distributors / Implementing Organizations

Ideas at Work

Countries

Cambodia

Manufacturing/Building Method

The Round Bio Sand Filter is manufactured on demand via a mould unit. The main parts of the mould unit are shown in the exploded view below are: 1) the puller, 2) an inner mould, and 3) outer mould.

The mould is bolted together, turned upside down and fitted with a copper outlet pipe. A concrete mix is then poured in the mould and compacted down. After several hours the puller is used to remove the inner mould after which the outer mould can be removed revealing the finished filter shell. The filter is then filled with sand and gravel layers.

The mould is bolted together, turned upside down and fitted with a copper outlet pipe. A concrete mix is then poured in the mould and compacted down. After several hours the puller is used to remove the inner mould after which the outer mould can be removed revealing the finished filter shell. The filter is then filled with sand and gravel layers.

Intellectural Property Type

Select Type

User Provision Model

No longer available for purchase.

Distributions to Date Status

Unknown.

Target use case

Household use

Manufacturer-specified flow rate (L/hr)

60

Bacteria reduction

87.9-98.5% removal

Protozoa reduction

More than 99.9 removal under laboratory testing

Virus reduction

70-99% removal under laboratory testing

Heavy metals and/or arsenic reduction

Unknown

Maximum recommended influent turbidity level (NTU)

Unknown

Effluent turbidity levels (NTU)

85-95% turbidity removal

Manufacturer-specified volume between cleaning (L)

Unspecified

Material of construction

Concrete, sand

Design Specifications

The IaW Round BSF is based on a design by MedAir and has a ‘round’ form instead of a ‘square’ form typical of most BSF units, reducing the mass and material costs of the unit. This design also makes it easier to move the unit by rolling it on its bottom edge. This is achieved by relatively simple modifications to a standard round cement drain pipe moulds.

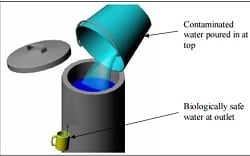

To operate the IaW BSF, contaminated water is poured into the unit at the top. The water passes through the diffuser plate and the sand and gravel layers. Head pressure pushes water through the copper pipe in the base to the outlet point. Biological contamination is reduced through the actions of adsorption; mechanical filtering, predation (biological layer) and natural die off. The typical flow rate of the unit is around 60 L/hr.

Dimensions of the finished BSF: Outer diameter: 35 cm; Inner diameter: 30 cm; Height: 95 cm; Weight: 60 kg

Dimensions of the finished BSF: Outer diameter: 35 cm; Inner diameter: 30 cm; Height: 95 cm; Weight: 60 kg

Technical Support

Users are responsible for maintenance and repair.

Replacement Components

This is no longer in production.

Lifecycle

Unknown.

Manufacturer Specified Performance Parameters

The typical flow rate of the unit is around 60 L/hr.

Vetted Performance Status

The Biosand Filter (BSF) is a proven technology, which removes pathogens such as bacteria, protozoa and helminth. BSFs are also somewhat effective for the removal of virus (CAWST 2009). Physical parameters such as turbidity and iron are also eliminated from drinking water. However, dissolved chemicals (such as organic pesticides or arsenic) are not removed. The treated water generally has an agreeable colour, taste and odour. The table below shows the biosand filter treatment efficiency in removing pathogens, turbidity and iron (adapted form CAWST 2009). Additional BSF evaluations have been aggregated by CAWST and include randomized controlled trials and field studies. Additional BSF evaluations have been aggregated by CAWST and include randomized controlled trials and field studies.

Safety

No cited hazards.

Complementary Technical Systems

Safe water storage.

Academic Research and References

Significant research has been conducted on BSF technology. A comprehensive list is available via CAWST.

Examples include:

Biosand filter literature summary – CAWST

An Assessment Of Continued Use And Health Impact Of The Concrete Biosand Filter In Bonao, Dominican Republic – American Journal of Tropical Medicine and Hygiene

“Biosand Filter,” Sswm.info. Available: https://sswm.info/water-nutrient-cycle/water-purification/hardwares/point-use-water-treatment/biosand-filter

Compliance with regulations

Although Biosand filters are known to reduce pathogen load in drinking water, this technology does not consistently meet WHO requirements.

Evaluation methods

Evaluation methods for this specific design of Biosand filter has not been evaluated. However, Biosand filters have been evaluated both in field and laboratory settings across the globe.

Other Information

None.

Agriculture

January 10, 2024

Implemented by

NativeEnergy

Agriculture

January 10, 2024

Implemented by

Dr. David Manz, University of Calgary

Agriculture

January 10, 2024

Implemented by

Dr. David Manz, University of Calgary

Agriculture

December 29, 2023

Implemented by

Sawyer

Agriculture

January 11, 2024

Implemented by

Doulton

Agriculture

January 2, 2024

Implemented by

Village Water Filters, Inc.

Agriculture

December 28, 2023

Agriculture

January 5, 2024

Implemented by

Universidad Tecnológica de Pereira (UTP)

Agriculture

December 29, 2023

Implemented by

Sawyer

Agriculture

January 24, 2024

Implemented by

Gift of Water

Have thoughts on how we can improve?

Give Us Feedback