Agriculture

June 24, 2024

AFD-1 Water Flow Sensor

Read SolutionImplemented by

Charity: water

Updated on September 26, 2023

·Created on September 15, 2017

A biomass-fueled water pasteurizer that is designed for institutions such as schools, dormitories, or refugee camps.

Originally designed by Institutional Energy Solutions (IES) (previously InStove) the water pasteurizer is a gravity-fed unit that kills microorganisms by heating water to the pasteurization temperature of 71 ºC and cooling it back down to safe drinking temperature. The system is housed in a 60 L pot and is designed to work with 60 L and 100 L cookstoves, but could potentially be used with other heat sources. The flow rate depends on the water inlet pressure, ranging from 3-8 L/min. Interview with designer

This technology is currently not available on the market.

Market Suggested Retail Price

$2,400.00

Target Users (Target Impact Group)

Distributors / Implementing Organizations

Seeds of Hope International Partnerships (SoHIP) in Zambia and MAPLE Microdevelopment in Uganda

Manufacturing/Building Method

The product is in the prototype phase and is not yet manufactured.

Intellectural Property Type

Trademarked

User Provision Model

Unknown

Distributions to Date Status

The product is in the prototype phase and is not yet distributed.

Deactivation mechanism

Pasteurization

Energy source

Cookstove

Manufacturer-specified water treatment rate (L/hr)

180 – 480 L/hr (3- 8 L/min)

Bacteria reduction

6 log

Virus reduction

6 log

Protozoa reduction

Unknown

Heavy metals and/or arsenic reduction

Unknown

Maximum recommended influent turbidity level (NTU)

Unknown

Effluent turbidity levels (NTU)

Unknown

Safe water storage capacity (L)

20 L

Design Specifications

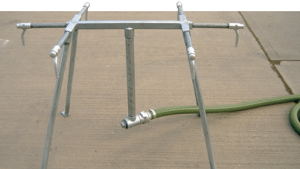

The water pasteurizer comprises of heating coils, a heat exchanger, and regulating thermostatic valve - all housed in a 60 L pot, and is designed to work with 60 L and 100 L cookstoves but could potentially be used with other biomass heat sources. Water is gravity fed from an elevated tank (3-4.5 m) and enters into the hot-side of the heat exchanger, then it passes through a coil where it increases in temperature. Next, a thermostatic valve regulates the system by only opening if the temperature of the water is above 71 °C. Water then flows through additional piping before re-entering the heat exchanger and cooling down to room temperature as it exits the system.

Technical Support

Contact the designer

Replacement Components

Some components can be available in local hardware stores, otherwise, contact the manufacturer.

Lifecycle

Estimated 10 yearsInterview with designer

Manufacturer Specified Performance Parameters

The product meets WHO requirements for drinking water while using up to 97% less wood per liter compared to boiling over an open fire.Interview with designer

Vetted Performance Status

Laboratory testing was conducted by Oregon State University and found a 99.9999% reduction in E. coli through the pasteurization unit in all samples and an average clean water production rate of 6.7 L per minute. The steady-state production of clean water required an average of 5.5 g of dry wood equivalent per liter of water pasteurized or 106 kJ of energy per liter. When accounting for system startup, it required 9.1 g of dry wood equivalent per liter of pasteurized water produced or 175 kJ of energy per liter.

Safety

Handling firewood and feeding the stove presents a reduced burn hazard compared to a typical open cooking fire. The pasteurization unit is designed to cool the water down using a heat exchanger so that the water at the outlet does not exceed 20 °C and does not present a burn hazard.

Complementary Technical Systems

The designer specifies that off-the-shelf or purpose-built filters can be connected in-line with the pasteurizer to remove non-microbial contaminants present in a particular water source such as sediments, metals, or synthetic organic compounds.

Academic Research and References

Burleson G, Caplan D, Mays C, et al., 2020, Computational Modeling and Empirical Analysis of a Biomass-Powered Drinking Water Pasteurization Technology, MDPI.

Burleson, G., Tilt, B., Sharp, K. and MacCarty, N., 2019. Reinventing boiling: A rapid ethnographic and engineering evaluation of a high-efficiency thermal water treatment technology in Uganda. Energy Research & Social Science, 52, pp.68-77.

Burleson, G., MacCarty, N., Sharp, K. and Tilt, B., 2018, August. An Interdisciplinary Mixed-Method Approach to the Evaluation of a Novel Water Treatment Technology in Eastern Uganda. ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference.

MacCarty N, Burleson G, Moses N, et al., 2017, Design and Testing of a High-Efficiency Rapid Throughput Community-Scale Water Pasteurization System, ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference.

Compliance with regulations

Meets WHO requirements for drinking water and US-EPA regulations for coliform and virus reduction.Interview with designer

Other Information

Received the Impact Invention Award from the Lemelson Foundation in 2017.

Agriculture

June 24, 2024

Implemented by

Charity: water

Agriculture

January 16, 2024

Implemented by

George Greene III, PE, PhD

Agriculture

January 10, 2024

Implemented by

Evenproducts

Agriculture

January 24, 2024

Implemented by

AidGear

Agriculture

January 11, 2024

Implemented by

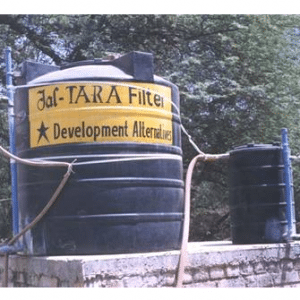

TARA

Agriculture

January 11, 2024

Implemented by

Kohler

Agriculture

December 12, 2023

Implemented by

Safi Water Treatment Solutions

Agriculture

December 29, 2023

Implemented by

Sawyer

Agriculture

January 24, 2024

Implemented by

Nanyang Technological University (NTU) Singapore

Agriculture

December 7, 2023

Implemented by

Agualogic

Have thoughts on how we can improve?

Give Us Feedback