Agriculture

November 22, 2023

Integrated Resuscitation Systems

Read SolutionImplemented by

GE (General Electric)

Updated on January 16, 2024

·Created on October 5, 2020

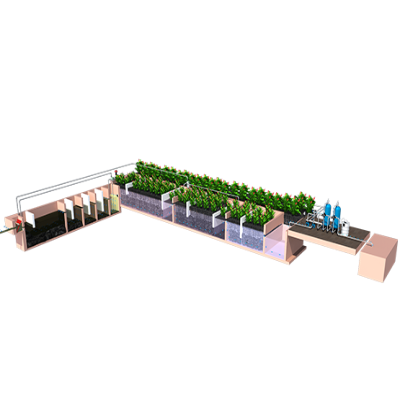

The Integrated Wetland Technology is a natural sewage treatment system which uses wetland vegetation, soils, and microbial assemblages.

The Integrated Wetland Technology is a primary, secondary, and tertiary natural engineered wastewater treatment system, delivered by Emergy Enviro Pvt. Ltd. The design replicates the natural process involved in wetland vegetation, soils, and microbial assemblages to assist the treatment of wastewater. Treated water from the system can be used for irrigation, gardening, and toilet flushing.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$1,339,755.00

Target Users (Target Impact Group)

Public Sector Agencies

Distributors / Implementing Organizations

This product is distributed by Emergy Enviro Pvt. Ltd, a SINE-IIT Bombay company.

Competitive Landscape

Direct competitors include AnoxKaldnes Moving Bed Biofilm Reactor, Sequential Batch Reactor, Membrane Biofilm Reactor, and Decentralized Wastewater Treatment Systems (DEWATS).

Regions

Worldwide

Manufacturing/Building Method

This product is built on site by the manufacturer.

Intellectural Property Type

Trademark

User Provision Model

This product can be acquired by contacting Emergy Enviro Pvt. Ltd.

Distributions to Date Status

Unknown

Flow rate (L/min)

69.44 L/min – 694.44 L/min. Flow rate is dependent on site specifications.

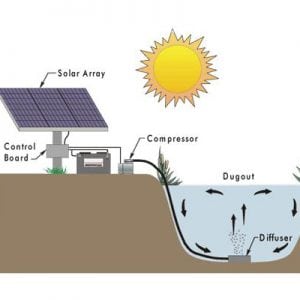

Power Supply Type

No power required

Technology type

Sedimentation, primary clarifier, settler, digester, aeration, sand filter, activated carbon, disinfection unit

BOD Removal Efficiency

93%

COD removal efficiency

87%

NH4-N Removal Efficiency

95%

TSS removal efficiency

93%

Total Phosphorus Removal Efficiency

57%

Fecal Coliform Removal Efficiency

Unknown

Design Specifications

The Integrated Wetland Technology is comprised of two stages which acts as primary and secondary wastewater treatment, with optional tertiary treatment.

The first section is the Primary Solid Removal Tank (PSRT), which acts as the primary clarifier. This consists of a settler, digester and aeration unit to remove TSS (70 to 80%) and BOD (45 to 55%). Vent pipes are equipped to remove odour.

The second section is a planted bed which consists of gravel media and various wetland plants such as Colocasia Esculenta, Canna Indica, Cyperus alternifolus. This stage removes BOD (85 to 95%). The two-stage management system cleans the gravel media without removal, prevents choking in the media and prevents overflow.

Treated sewage from the planted bed can be subjected to tertiary treatment such as a pressure sand filter, activated carbon unit and disinfection unit.

Technical Support

Unknown

Replacement Components

Unknown

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

The manufacturer cites minimal operational energy requirement, no technical expertise required for operation, minimal maintenance costs, modular design, methane capture and reduced environmental impacts as performance targets.

Vetted Performance Status

Integrated Wetland Technology has been tested by the Tennessee Valley Authority for the removal of COD (84%+), ammonia nitrogen (93%) and phosphorus (>90%).

Safety

Wastewater must be handled, treated and disposed of in accordance with hygiene and CPCB environmental standards.

Complementary Technical Systems

Treated wastewater can be discharged for secondary uses such as irrigation and toilet flushing purposes.

Academic Research and References

Urbanc-Bercic, O., Bulc, T., 1995, Integrated constructed wetland for small communities, Water Science and technology 32(3): 41-47.

Behrends, L., et al., 2007, Integrated constructed wetland systems: design, operation, and performance of low-cost decentralized wastewater treatment systems, Water Science Technology 55(7): 155-161.

Stefanakis, A. I., 2019, The role of constructed wetlands as green infrastructure for sustainable urban water management, Sustainability 11(24): 6981.

Compliance with regulations

The discharged water meets discharge standards set by the CPCB.

Evaluation methods

The manufacturer cites BOD removal of 87-93% as evaluation criteria.

Other Information

Agriculture

November 22, 2023

Implemented by

GE (General Electric)

Agriculture

June 22, 2024

Implemented by

Lumeter Networks

Agriculture

June 10, 2024

Implemented by

Seameo Innotech

Agriculture

December 18, 2024

Implemented by

Kite Power Systems (KPS)

Agriculture

August 19, 2024

Implemented by

WERL Univesity of Toronto

Agriculture

September 18, 2024

Implemented by

Greenhouse Ventures

Agriculture

January 12, 2024

Implemented by

VIP

Agriculture

December 19, 2024

Implemented by

CLIMATENZA

Agriculture

June 23, 2024

Implemented by

LoooP Creative Ltd

Agriculture

January 10, 2024

Implemented by

NRSRelief

Have thoughts on how we can improve?

Give Us Feedback