Agriculture

March 4, 2024

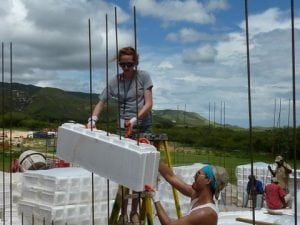

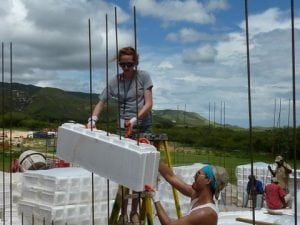

Lazarian Polystyrene Insulated Concrete Forms

Read SolutionImplemented by

Lazarian World Homes

Updated on March 6, 2024

·Created on September 19, 2018

Micro Concrete Roofing (MCR) tiles are made of a mixture of cement, sand, and water as an alternative roofing material.

Micro Concrete Roofing (MCR) tiles are made of concrete (mixture of cement, sand and cement) as an alternative to traditional roofing materials such as thatch, iron sheeting, or asbestos.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$5.33

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises, NGOs

Distributors / Implementing Organizations

MCR tiles are marketed and distributed by different brand names such as TARAcrete and DURAcrete in India, or Tejacreto in Peru.

Competitive Landscape

Direct competitors include HyPar Thin Shell Concrete Roof, ModRoof, and Corrugated Metal Panels.

Regions

Worldwide

Manufacturing/Building Method

Tiles can be produced on the construction site, or made-to-order or mass-produced at a production facility and then transported to the site.

Intellectural Property Type

Select Type

User Provision Model

User can manufacture the tiles with the correct equipment, get them through a contractor, or directly from a manufacturer.

Distributions to Date Status

Unknown

Unit dimensions (cm)

60 x 60 cm2

Primary materials

Cement, graded sand, and stone

Complimentary materials

None

Fire Resistance (hr)

Unknown

Thermal Insulation Capacity

Relatively low insulation, but much higher than a galvanized iron sheet

Compressive Strength (MPa)

0.012 MPa

Suitable Climates

All climates

Design Specifications

To manufacture a micro concrete tile, it is necessary to have molds, a tile vibrator, plastic sheets, batching boxes, a tank for curing in water, and a table. The materials needed are sand, cement and water. Pigments are optional to produce colored tiles.

The dry materials are mixed first in the correct proportions. The water is added gradually, continually mixing, until it is workable.

Then the vibrator is placed on the table. A plastic sheet must be placed on top. The mix is then put on the plastic sheet, working it while the vibrator is on for 30 seconds. The tile nib is then attached to the tile. Take the whole tile, with the plastic sheet, and place it on the mold. Leave overnight.

The next day, the tiles would be removed from the molds and left inside a water tank to cure for at least 5 days. Then remove and leave to cure with air for 20 days. During this curing time they should be sprayed with water twice a day.

This process can also be viewed on online videos.

MCR tiles can vary in size, shape and color. There are different molds to create shapes such as ridges or corrugated shapes. If pigments are added to the mix, different colors can be achieved. Red is the most common color. MCR tiles are much lighter than standard concrete roofs and reduce noise when rain falls on them.

The roof structure is a group of purlins and rafters made of either timber or metal, and use triangular trusses if necessary. The spacing of these elements depends on the slope, climate, and tile weight. The pitch of the roof is at least 22°, and 30° in places where it rains heavily. To attach the tiles, it is necessary to place battens (made of wood or steel) with no more than 40 cm of spacing. These should be able to hold the tiles' weight and the weight of a worker.

Technical Support

A general contractor could be able to provide assistance. The roof structure must be designed according to user's needs. The MCR tiles are just placed on the structure and attached with a nail or a wire, so any worker can learn to install them.

Replacement Components

A broken tile can be replaced with a new one of the same type

Lifecycle

20 years

Manufacturer Specified Performance Parameters

The MCR tiles should be lightweight, aesthetically pleasing, cost-effective, and durable. They offer security and comfort for the user, protecting from sun, heavy rain, and frost.

Vetted Performance Status

A study conducted to test the strength and durability of MCR tiles found that they had comparable performance to conventional roofing materials.

Safety

During installation, the user is exposed to the expected construction risks, such as heights and sharp tools

Complementary Technical Systems

MCR can be paired with many other construction systems for walls such as Earthen Bags or Bottle Bricks

Academic Research and References

Jayasinghe, C., JDe. Silva, M., Dissanayake, D., Fernando, C., 2006., Engineering Properties of Micro Concrete Roofing Tiles,

Khanna P, 2011. Material and Technology – An inventory of select

materials and technologies for building construction. Project report to CDKN, 2011.Development Alternatives Group, New Delhi.

“Micro Concrete Roofing Technology”, Eco building Advisory Unit, accessed on March 6, 2024, https://societyarts.tripod.com/04sshe/wp/mcr.pdf

Skat, 2017. MCR – Roofing System, pages 1-2.

“Roofing ROOF STRUCTURE MCR Tiles Installation”, New Zealand Digital Library, accessed on March 6, 2024, https://www.nzdl.org/cgi-bin/library?e=d-00000-00—off-0cdl–00-0—-0-10-0—0—0direct-10—4——-0-1l–11-en-50—20-about—00-0-1-00-0–4—-0-0-11-10-0utfZz-8-00&cl=CL2.16&d=HASH01d9a1111b8d221ca7a65576.12.1>=1

Compliance with regulations

Codes and regulations differ by country. For example, Germany has a certification program, and the Bureau of Indian Standards and ASTM have published standards and specifications.

Other Information

No specialized infrastructure is needed to start a production facility. It is required to have access to the raw materials (sand, cement), water, storage room, electricity and a shed or roofed area to avoid harsh weather. The raw materials can usually be delivered by truck. Electricity is essential to have the vibration tables running. The storage room would be used to keep raw materials and finished tiles.

Examples of manufacturers: TARAcrete and DURAcrete in India, or Tejacreto in Peru.

Similar patent

Video: How to Make a Micro Concrete Roof Tile

“Micro-concrete Roofing Tiles”, Society arts, accessed on March 6, 2024, https://societyarts.tripod.com/04sshe/mcrt.html

Agriculture

March 4, 2024

Implemented by

Lazarian World Homes

Agriculture

March 1, 2024

Implemented by

George Nez and Albert Knott

Agriculture

March 7, 2024

Implemented by

Technology for Tomorrow (T4T) Africa

Agriculture

February 19, 2024

Implemented by

Earthquake Engineering Research Institute (EERI)

Agriculture

November 30, 2024

Implemented by

Sustainable Community Development Services (SCODE)

Agriculture

December 2, 2024

Implemented by

NTN Global

Agriculture

January 19, 2024

Implemented by

Donico Inter Co., Ltd

Agriculture

December 18, 2024

Implemented by

SkyWind Energy GmbH

Agriculture

December 26, 2023

Implemented by

Ecofrost Technologies, a subsidiary of Ecozen.

Agriculture

January 5, 2024

Implemented by

MeraGao Power

Have thoughts on how we can improve?

Give Us Feedback