Agriculture

January 3, 2024

MSR SE200 Community Chlorine Maker

Read SolutionImplemented by

Cascade Designers, Inc

Updated on January 27, 2024

·Created on September 4, 2020

The MSR-Stanford Venturi Doser delivers consistent doses of chlorine to water at public water kiosks.

The MSR-Stanford Venturi Doser is a chlorine doser developed by MSR Global Health, PATH, SWAP Kenya, Tufts University, and Stanford University. The Venturi Doser is installed directly onto the water system of drinking water kiosks to automatically inject a precise dose of chlorine as the water flows. The doser is based on the venturi effect. Water flows through the device and sucks in the appropriate amount of liquid chlorine to dose the water. The dozer has no moving parts and requires no electricity to operate.

Target SDGs

SDG 6: Clean Water and Sanitation

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$150.00

Target Users (Target Impact Group)

Community

Distributors / Implementing Organizations

This product was implemented during a study in Kenya by Safe Water and Aids Project (SWAP) in partnership with Stanford University.

Competitive Landscape

Direct competitors include PurAll Water Purification, Dispensers for Safe Water, Lotus Water Chlorine Dosing Device, and Zimba automatic chlorine dispenser.

Countries

Bangladesh, Kenya

Manufacturing/Building Method

The prototype is currently manufactured by MSR in Seattle. The chlorine solution can be sourced locally.

Intellectural Property Type

Trademark

User Provision Model

The product is still in its prototype stage and cannot be acquired by users currently.

Distributions to Date Status

The product has been installed at 170 kiosks supplying to 10,000 people to measure long term performance.

Active Chemical and concentration (%)

Sodium hypochlorite 1.2%

Form

Liquid

Dosing method: Batch or flow-through

Flow-through

Dosing method: Automatic or manual

Automatic

Dosing quantity

1-1.5 mg/L for 20-40 L/min

Contact time (min)

30 mins

Target free disinfectant residual (mg/L)

0.2 – 1.2 mg/L

Bacteria reduction

2 log (E. coli)

Virus reduction

2 log (enteroviruses)

Protozoa reduction

3 log (E. Histolytica, G. Lambilia, Cryptosporidium.)

Heavy metals and/or arsenic reduction

None

Treatment lifespan (days)

7 days if treated water is stored in a narrow neck container with a tight fitting.

Maximum recommended influent turbidity level (NTU)

10 NTU

Design Specifications

The MSR/Stanford Venturi Doser is installed directly into the water systems in public kiosks and automatically injects water with a precise dose of chlorine as it produces water for customers. The product uses the venturi effect, which means the product requires no moving parts or electricity. Liquid chlorine fills the chlorine tank which flows into the float tank. Water flows through the device from a larger to a smaller section and sucks an appropriate amount of liquid chlorine to treat the water before being discharged to the customer. The chlorinator uses commercially available Waterguard as its liquid source.

Technical Support

During trials of the prototype technical support was provided by the manufacturer.

Replacement Components

Liquid chlorine

Lifecycle

10 years

Manufacturer Specified Performance Parameters

The manufacturer cites a dosing of 1 ppm and 1.5 ppm free chlorine over a flow rate range of 20-40 L/min as performance criteria.

Vetted Performance Status

SWAP in partnership with Stanford University conducted a study across 170 water kiosks supplying to 10,000 people living in Bangladesh and Kenya. It was determined that point-of-chlorination reduced contamination of fecal indicator bacteria in drinking water by 70% and reduced child diarrhea in children by 23% (95% CI 9-35%; N=4227).

Safety

The World Health Organization (WHO) states free residual chlorine post chlorine dosing should not exceed 5 mg/L if it is to be considered for lifetime use.

Complementary Technical Systems

Filtration prior to treatment can reduce the amount of chlorine required if the source water is turbid.

Academic Research and References

Germann, L., 2019, Evaluation of suitable automatic chlorination devices for gravity-driven membrane water kiosks in Uganda. Masters thesis, Eawag: Swiss Federal Institute of Aquatic Science and Technology, Dübendorf, Switzerland.

Powers, J., et al., 2018, Evaluating the Technical Performance and Sales Viability of a Novel Venturi Chlorine Doser at Drinking Water kiosks in Kisumu, Kenya. 2018 Water and Health: Where Science meets Policy.

“Safe Water & AIDS Project.” n.d. Swapkenya.Org. https://www.swapkenya.org/

Thesis, Master. n.d. Eawag.Ch. https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/schwerpunkte/SWP/automatic_chlorination_devices.pdf

“Goal 6.” n.d. Sdgs.Un.Org. https://sdgs.un.org/goals/goal6

N.d. Fhi360.Org. https://hip.fhi360.org/file/21859/PG%20Unit%203.pdf

N.d. Swapkenya.Org. https://www.swapkenya.org/wp-content/uploads/2018/02/ANNUAL-REPORT-2017-Final.pdf

“WaterGuard.” 2015. Engineering For Change. August 27, 2015. https://www.engineeringforchange.org/solutions/product/waterguard/

“Listing Category Search Page.” n.d. Nsf.Org. https://info.nsf.org/Certified/PwsChemicals/Listings.asp?CompanyName=&TradeName=&ChemicalName=Sodium+Hypochlorite&ProductFunction=&PlantState=&PlantCountry=&PlantRegion=

Compliance with regulations

Sodium hypochlorite products for drinking water treatment, used in the Venturi doser, comply with NSF/ANSI/CAN 60 to ensure chemicals are safe at maximum dose and impurities are below the maximum allowable limit.

The World Health Organisation (WHO) Guidelines for Drinking Water Quality list Sodium Hypochlorite with concentrations between 0.5% and 1% as a point-of-use water treatment method.

Evaluation methods

The Venturi Doser is evaluated for the removal of faecal indicator bacteria (70%) at point-of-chlorination during randomized trials.

Other Information

None

Agriculture

January 3, 2024

Implemented by

Cascade Designers, Inc

Agriculture

June 23, 2024

Implemented by

LoooP Creative Ltd

Agriculture

January 10, 2024

Implemented by

NRSRelief

Agriculture

January 8, 2024

Implemented by

Gadgil Lab, University of California Berkeley

Agriculture

January 25, 2024

Implemented by

DEKA Research & Development

Agriculture

January 1, 2024

Implemented by

TATA Swach

Agriculture

January 3, 2024

Implemented by

Population Services International (PSI)

Agriculture

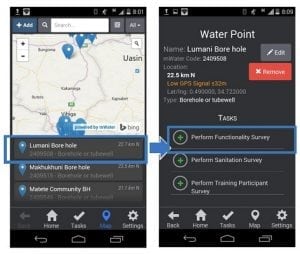

June 24, 2024

Implemented by

mWater

Agriculture

January 2, 2024

Implemented by

Aqua Research

Agriculture

January 24, 2024

Implemented by

AidGear

Have thoughts on how we can improve?

Give Us Feedback