Agriculture

August 29, 2024

Agriworks Mobile Irrigation Systems

Read SolutionImplemented by

Agriworks

Updated on March 7, 2024

·Created on October 2, 2018

The DOMO-System is a modular, fast-to-pitch emergency shelter designed by More than Shelters (MTS) for humanitarian crises. It can be adapted according to local climate, geographical circumstances or culture.

The DOMO-System is a modular, hexagonal dome tent designed by More than Shelters (MTS) for humanitarian crises. Its base is a fast-folding aluminium frame. Different fly sheet elements, “shells”, can be attached to the frame depending on the needs, and it can be exchanged over the seasons. It comes with a sturdy tarpaulin floor, two window elements, two door elements and two detachable vestibules. Each tent can be connected on all six sides to another unit. It can comfortably sleep 10 people or have 30 occupants for activities.

Target Users (Target Impact Group)

Distributors / Implementing Organizations

Manufacturing/Building Method

The DOMO systems come packed in two stackable boxes (measuring 1.2m x 0.8m x 0.3m each) with a gross weight of 140kg. It can be transported and set up in under 45 min by two untrained individuals. All tools needed are included in the toolbox. However, a stepladder is recommended.

Intellectural Property Type

Select Type

User Provision Model

Users can get the product online directly from the manufacturer or third party distributors such as Tundra and The Level Market.

Distributions to Date Status

There are DOMO systems currently being used as boarding schools and an orphanage in Nepal, shelters and protective rooms for women and children in Greece, and community spaces in refugee camps in Hamburg.

Footprint area (m²)

Internal volume (m³)

Material composition

The structure is made of hollow, sandblasted aluminium.

Cotton shell: 100% cotton, 285 g/m2, 350mm of hydrostatic head

TC shell: 65% polyester, 35% cotton, 185 g/m2, 1000mm of hydrostatic head

RS shell: 100% Ripstop polyester PU, 3000mm of hydrostatic head

SOLID shell (Under development): Insulating sandwich panels

Flammable Flash Point Temperature (°C)

Unknown.

Maximum snow load (kg/m²)

Maximum wind speed (km/h)

Design Specifications

The DOMO-Systems have three types of interchangeable shells of different material to switch according to need. There is a cotton shell for desert climates, a polyester and cotton shell for tropic weather and a polyester shell for winter. A solid shell is also under development, which would transform the unit into a more permanent shelter. The DOMO-system can be costumized to fit the needs of the client.

The DOMO comes in two transport boxes. The boxes can be used as a stepladder for installation. It weighs 131kg, and a 20ft container can fit 33, or in a 40ft container, 45 units.

Technical Support

Shelter can be installed by untrained individuals.

Replacement Components

Lifecycle

The structure lasts 10 years. The shell parts are interchangeable.

Manufacturer Specified Performance Parameters

The DOMO-System avoids "one size fits all" and so it seeks to adapt to individual and cultural needs, as well as climate and purposes. It is portable and does not require specialized training or tools to install.

Vetted Performance Status

It is currently going through tests for certification.

Safety

It is unknown as to whether sharp tools are needed to assemble the structure; some work is done from heights. There is no information available for combustibility/flame retardancy of materials.

Complementary Technical Systems

Academic Research and References

None found.

Compliance with regulations

awaiting response from the manufacturer

Other Information

There are packages that include all items needed for a specific humanitarian purpose, such as emergency accommodation, field offices and base camps, child-friendly spaces, schools and community centers.

The DOMO systems can also be acquired for cottaging and other commercial reasons.

Agriculture

August 29, 2024

Implemented by

Agriworks

Agriculture

January 11, 2024

Implemented by

BORDA

Agriculture

February 5, 2024

Implemented by

Gradian Health Systems

Agriculture

January 16, 2024

Implemented by

George Greene III, PE, PhD

Agriculture

December 18, 2023

Implemented by

Clivus Multrum

Agriculture

January 10, 2024

Implemented by

Niwa

Agriculture

November 22, 2023

Implemented by

GE (General Electric)

Agriculture

March 8, 2024

Implemented by

Pacific Consolidated Industries

Agriculture

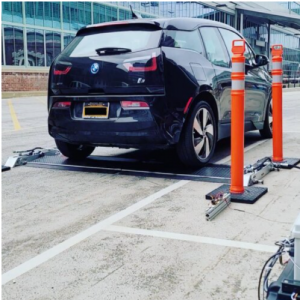

January 25, 2024

Implemented by

RoadPower Inc

Agriculture

February 4, 2024

Implemented by

Tank Connection

Have thoughts on how we can improve?

Give Us Feedback