Agriculture

August 15, 2024

Struvite Reactor Tank

Read SolutionImplemented by

EAWAG

Updated on January 12, 2024

·Created on October 1, 2020

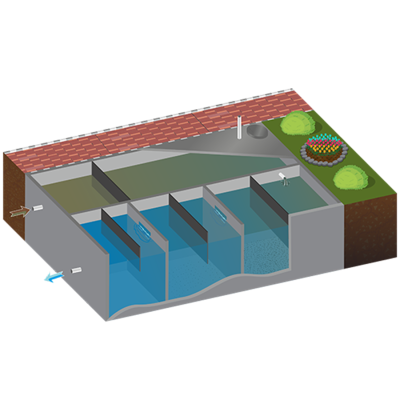

The NG-SEPCLEAN is a decentralized sewage treating septic tank developed to provide safe sanitation through treated wastewater.

The NG-SEPCLEAN is a decentralized sewage treating septic tank developed to provide safe sanitation through treated wastewater, developed by Emergy Enviro Pvt. Ltd. The design is applicable where traditional septic tanks are unsuitable such as lack of space for a drain field, high water tables, proximity to wells or other bodies of water, and inadequate percolation. The NG-SEPCLEAN is designed for a high rate of digestion, low footprint, and reuse of treated wastewater.

Target SDGs

SDG 6: Clean Water and Sanitation

Target Users (Target Impact Group)

Household, Community, Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

Emergy Enviro Pvt. Ltd, a SINE-IIT Bombay company

Competitive Landscape

Direct competitors include Johkasou, Decentralized Wastewater Treatment Systems (DEWATS), and The Biofil Digester.

Countries

India

Manufacturing/Building Method

Unknown

Intellectural Property Type

Trademark

User Provision Model

This product can be acquired by contacting Emergy Enviro Pvt. Ltd.

Distributions to Date Status

As of 2020, the NG-SEPCLEAN is implemented at 8 sites across India.

Flow rate (L/min)

Flow rate dependant on site specifications.

0.219-0.729 L/min (Households)

1.458-21.875 L/min (Public toilets)

Power Supply Type

No power required

Technology type

Sedimentation, Flocculation, Anaerobic, Aerobic, Filtration

BOD Removal Efficiency

70-80%

COD removal efficiency

75-85%

NH4-N Removal Efficiency

40-50%

TSS removal efficiency

75-90%

Total Phosphorus Removal Efficiency

30-35%

Fecal Coliform Removal Efficiency

80-90%

Design Specifications

The NG-SEPCLEAN requires less land space compared to traditional septic tanks. The principle components and functions include:

The system flow rate is dependant on the size and site specifications.

Technical Support

Provided by the manufacturer.

Replacement Components

Unknown

Lifecycle

30-40 years

Manufacturer Specified Performance Parameters

The manufacturer specifies the following as performance targets:

Vetted Performance Status

The average removal efficiencies of the Decentralised Wastewater Treatment System (DEWATS) in Nepal is 96% TSS, 90% BOD5, 90% COD, 70% NH4–N, 26% TP and 98% FC.

Safety

Wastewater must be handled, treated and disposed of in accordance with hygiene and environmental standards.

Complementary Technical Systems

The effluent from these digesters can be further treated through Phytorid technology as a polishing step and then dispose into the river.

Academic Research and References

Singh, S., et al., 2009, “Performance of an anaerobic baffled reactor and hybrid constructed wetland treating high-strength wastewater in Nepal – A model for DEWATS“, Ecological Engineering 35: 654-660.

Kerstens, S. M., et al., 2012, “Evaluation of DEWATS in Java, Indonesia“, Journal of Water, Sanitation and Hygiene for Development 2: 254-265.

Reynaud, N., Buckley, C., 2015, “Field-data on parameters relevant for design, operation and monitoring of communal decentralized wastewater treatment systems (DEWATS)“, Water Practice and Technology 10: 787-798.

Compliance with regulations

Design and construction in compliance with IS 2470-2 (1985): Code of practice for installation of septic tanks, Part II: Secondary treatment and disposal of septic tank effluent.

Evaluation methods

The manufacturer cites solid and organic removal efficiency and 75-90% TSS removal evaluation criteria.

Other Information

Agriculture

August 15, 2024

Implemented by

EAWAG

Agriculture

February 4, 2024

Implemented by

Tank Connection

Agriculture

June 23, 2024

Implemented by

LoooP Creative Ltd

Agriculture

January 10, 2024

Implemented by

NRSRelief

Agriculture

January 22, 2024

Implemented by

Sanivation

Agriculture

December 13, 2023

Implemented by

change: Water

Agriculture

December 27, 2023

Implemented by

Nippon Basic Co. Ltd.

Agriculture

January 8, 2024

Implemented by

Gadgil Lab, University of California Berkeley

Agriculture

September 19, 2023

Implemented by

Grundfos

Agriculture

January 11, 2024

Implemented by

Precious Plastic

Have thoughts on how we can improve?

Give Us Feedback