Agriculture

December 17, 2024

Flexi Biogas BG5

Read SolutionImplemented by

Biogas International Limited

Updated on December 17, 2024

·Created on May 23, 2016

The Nopalimex is a biodigester powered by a cactus (nopal) widely found in Mexico.

Nopalimex is a biodigester developed by Miguel Aké entirely powered by nopal, a cactus. The plant benefits from economies of scale and low transport cost, as the crop is grown around the biodigester plant. The biogas produced is used in the factory for making corn and cactus chips, as well as in a gen-set for electricity. Some is cleaned of carbon dioxide and provided as bio-methane, which can be used in modified vehicles.

Target SDGs

SDG 7: Affordable and Clean Energy

SDG 8: Decent Work and Economic Growth

Market Suggested Retail Price

$2,170,000.00

Target Users (Target Impact Group)

Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

Nopalimex is the sole distributor in Mexico. This firm generates gas and electricity using nopal biomass.

Competitive Landscape

Direct competitors include G2E Biomass Gasification Plant.

Countries

Brazil, Chile, Colombia, Ecuador, India, Mexico

Manufacturing/Building Method

Plants are designed and custom-built individually. Nopal plantation is liquefied by a special machine. The resulting pulp is mixed in large tanks with water at 38 degrees C which is the required temperature to break down nopal and release methane. Further treatment with sulphuric acid extracts carbon dioxide, giving the plant a 96% concentration of methane at a production rate of eight tons a day.

Intellectural Property Type

Patent

User Provision Model

Users can obtain the product directly from Nopalimex.

Distributions to Date Status

Two plants to date in the town of Zitacuaro, in central Michoacan state, the first to aliment the company 'El Manjar del Campo' that produces tortillas, the second used to fuel the town's vehicle fleet.

Output energy product

Unknown

Average daily biogas production (m3/day)

600 m3/day – 800 m3/day

Description of waste source(s)

Dried cactus (nopal) leaves

Waste input requirements (kg per hour or day)

7,257 kg of per day

Description of other input requirements

Unknown

Other input requirements (amount per hour)

Unknown

System dimensions (m)

Unknown

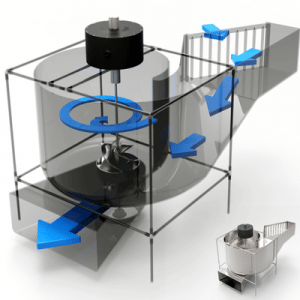

Design Specifications

The system includes a well-insulated above-ground container. The biogas digester processes prickly pears (from the cactus) into biomethane. The pears are ground up into a soup, mixed with manure and fermented in a digester. The biogas generated is then cooled to dewater it.

Technical Support

May be provided by the manufacturer

Replacement Components

N/A

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

To convert nopal leaves into a source of usable energy.

Vetted Performance Status

Research was conducted by scientists in Oxford University on the prickly pear cacti and they found that the plant can help produce more food in drought-stricken areas. Since the cacti absorbs high quantities of water, after digestion biogas is made, liquid and solid fertilizer will be left over. This in turn is used to better cultivate crops in areas that could not otherwise support them.

Safety

There are some dangers associated with biogas, including fire hazard, explosion, gas leaks, and negative pressure.

Complementary Technical Systems

None

Academic Research and References

Aké, M., 2017, Biogás con nopal para vehículos en sustitución de combustibles fósiles, México.

Advanced Biofuels USA. 2017. Methane Plant Is the First to Use Nopal. Mexico News Daily, March 22, 2017.

Instituto Mexicano de La Propiedad Industrial | Gobierno | Gob.mx. n.d. www.gob.mx.

World’s First Cactus Biogas Plant Opens in Mexico. 2016. Yucatan Times.

Mason, P.M., Glover, K., Smith, J.A.C., Willis, K.J., Woods, J., Thomson, I.P., 2015, The potential of CAM crops as a globally significantbioenergy resource: moving from ‘fuel or food’ to fuel and more food. Energy & Environmental Science. Vol 8. Issue 8. pp 2320-2329.

Compliance with regulations

None

Evaluation methods

Unknown

Other Information

The biodigestor was developed with expert advice from the National Polytechnic Institute of Mexico, the Autonomous University of Chapingo and the Electric Power Research Institute. Expert advisors have indicated that the good economics depend on having a good quality feed material easily accessible - in this case nopal (prickly pear).

Agriculture

December 17, 2024

Implemented by

Biogas International Limited

Agriculture

January 24, 2024

Implemented by

Hugh Piggott

Agriculture

December 17, 2024

Implemented by

Shenzhen Puxin Technology Co. Ltd.

Agriculture

December 17, 2024

Implemented by

Sun King

Agriculture

December 2, 2024

Implemented by

Turbulent

Agriculture

December 2, 2024

Implemented by

Energy Systems & Design

Agriculture

December 17, 2024

Implemented by

ATEC Biodigesters International

Agriculture

January 28, 2024

Implemented by

Burro

Agriculture

January 25, 2024

Implemented by

d.light

Agriculture

January 27, 2024

Implemented by

M-KOPA

Have thoughts on how we can improve?

Give Us Feedback

Nopalimex is a biogas digester that processes prickly pears into

biomethane. The pears are ground up into a soup, mixed with manure and

fermented in a digester. The biogas generated is then cooled to dewater it. The gas is also used in the factory for making corn and cactus

chips, as well as in a genset for electricity. Some is cleaned of carbon

dioxide and provided as biomethane, which can be used in modified

vehicles.

It is not clear what the biogas digester is made from, but the picture shows a well insulated above ground container, so it is probably made from steel. The plant benefits from economies of scale and also no transport cost, as the crop is grown around it.

The Nopalimex plant wortks well on the site for which it was made. There are minimal transport costs and economies of scale. They claim an electrcity cost less than half of that supplied by the electrcity grid.

It is not clear how many other sites would be suitable. The feed material, prickly pear, is very productive and locally available. There are probably several sites in Mexico that would be suitable.

It is a bespoke design, made individually for customers and their particular sites.

The plant seems to be very effective, using the particular feed material that is easily available (prickly pear – nopal). It uses a “standard” approach, of crushing the feed material, mixing it with dung and putting it in a steel tank CSTR. The good economics depend on having a good quality feed material easily accessible.