Agriculture

March 7, 2024

Updated on March 7, 2024

·Created on September 26, 2018

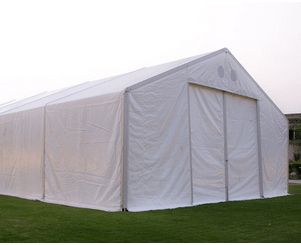

Rex Hall Mobile Storage Units (MSU) are flexible warehouses designed for easy shipping and considered as easily assembled in a day by 4-6 people in any emergency situation.

The Rex Hall Mobile Storage Unit was designed by NRS Relief to provide a flexible option to respond to any emergency situation. It can be assembled by a small group (4-6 people) in under a day. It was designed for shipping, making it accessible by land, water or air. It has adjustable base plates that facilitate installation on uneven ground.

The MSU is suited for warehouses, having the capacity to store food supplies and items, as well as refugee shelters or disaster response teams. In the correct configuration, it can house more than a hundred people. It can also be converted into temporary schools or hospitals as needed in each particular situation.

There are accessories such as flooring, insulation, heating, partitions, solar energy systems among others that can be added to the unit.

Target Users (Target Impact Group)

Distributors / Implementing Organizations

Manufacturing/Building Method

The MSUs are manufactured by H. Sheikh Noor-ud-Din & Sons (HSNDS) in Lahore, Pakistan. There are 8 stages of the MSU production process: (1) Fabric reception, (2) Cutting and welding, (3) Logo banner, (4) Web attachment, (5) Steel components, (6) Aluminum components, (7) Inspection, and (8) Packing and loading.

To assemble the shelter, a team of 4 to 6 people is recommended. The shelter can be setup quickly without the use of lifting equipment or scaffolding. The shelter's adjustable base plates allow the structure to be assembled on uneven terrain. NRS Relief provides an instructional video on proper assembly.

Intellectural Property Type

Select Type

User Provision Model

Crisis relief organizations can obtain directly from the manufacturer.

Distributions to Date Status

These MSU are used by the ICRC, IFRC, WFP, UNICEF, and UNHCR. The manufacturing facility has a production capacity of 100 MSU in a month, and keeps emergency stockpiles ready for deployment.

Intended number of occupants (#)

100 people

Speed of assembly

Unknown

Footprint area (m²)

Internal volume (m³)

1,392 m3

Material composition

Aluminum box profiles, hot-dipped galvanized steel apex, base plates, and PVC coated polyester cotton

Lifespan (years)

Unknown

Flammable Flash Point Temperature (°C)

Unknown

Maximum snow load (kg/m²)

Unknown

Maximum wind speed (km/h)

Suitable climates

Design Specifications

The Rex Hall Mobile Storage Units are shipped in 5 packages, occupying a total of 5.102 m3 and weighing 2,533 kg. Depending on the road weight restrictions of the destination country, a 20 ft container can be used to transport 5 shelters.

The MSU's outer tent component consists of the roof, wall, and gable covers, which are made from 700 gsm PVC coated polyester. The gable ends can be fitted with large ventilators.

The shelter can be extended with 10 x 4 m modules.

Markings and logos on the tent can be customized to the clients requirements.

Technical Support

A repair kit is supplied with every tent for holes and tears in the PVC fabric. Users can consult NRS Relief directly or the supplier for advice on repairs on aluminium or steel components.

Replacement Components

Unknown

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

The Rex Hall MSU aims to be easy, cost-effective to ship, while being flexible in any emergency situation. It should be easy to assemble with minimal manpower, even in rough terrain. Its flexibility permits applications beyond warehousing supplies, adding to the design any of the accessories that NRS Relief provides.

Vetted Performance Status

No third-party organizations have been conducted on the Rex Hall MSUs. NRS conducted fire testing on their fire retardant tarpaulins in 2014 and received an award for their Fire Retardancy solution.

Safety

There are mechanical hazards while assembling or dismantling the MSU. Safety helmet, shoes and gloves should be worn at all times. A single person should avoid carrying more than 20 kg. Equipment such as ladders or hammers should be maintained. The covers, floors or linens should not be packed wet.

Exercise extreme caution with fire; even with fire retardant technology there is still risk of open fire.

Complementary Technical Systems

NRS Relief offers complementary accessories, such as solar energy systems, fire alarms, LED lighting, etc.

Academic Research and References

None

Compliance with regulations

The manufacturing company, H. Sheikh Noor-ud-Din & Sons (HSNDS), has the following ISO certifications:

The fire retardant tents and tarpaulins have passed CPAI section 5 and 6 and ISO 4892-2, type A.

It complies with UNHCR/UNICEF/IFRC/ICRC/WFP Standards.

Other Information

There is a video detailing the assembly of a MSU.

The Fire Retardancy Solution won the annual Aid Innovation Challenge Award 2014 during the AidEx Summit in Brussels.

Agriculture

March 7, 2024

Agriculture

March 7, 2024

Agriculture

December 19, 2023

Implemented by

RealRelief

Agriculture

February 20, 2024

Implemented by

Intellectual Ventures Lab

Agriculture

August 20, 2024

Implemented by

Purdue University

Agriculture

February 5, 2024

Implemented by

Vestergaard

Agriculture

December 26, 2023

Implemented by

Ecofrost Technologies, a subsidiary of Ecozen.

Agriculture

June 30, 2024

Implemented by

Echo Mobile

Agriculture

June 22, 2024

Implemented by

Mobile Clinics & Hospitals

Agriculture

June 22, 2024

Implemented by

Odulair

Have thoughts on how we can improve?

Give Us Feedback