Agriculture

February 27, 2024

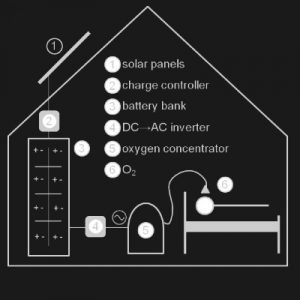

Solar-Powered Oxygen Delivery (SPO2)

Read SolutionImplemented by

Solar Oxygen

Updated on February 29, 2024

·Created on October 2, 2020

The Oxygen Reservoir System is an oxygen storage and filling vessel system.

The Oxygen Reservoir System is an oxygen storage vessel and a compressor pump. The vessel can be filled from any appropriate oxygen concentrator and stored for later use. The system can be used in the event of a power failure whereby the internal pressure of the vessel will drive the outflow of oxygen.

Target SDGs

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$2,300.00

Target Users (Target Impact Group)

Small and Medium-sized Enterprises, Public Sector Agencies

Distributors / Implementing Organizations

Diamedica

Countries

Benin, Burkina Faso, Cameroon, Central African Republic, Congo (Brazzaville), Congo (Kinshasa), Gambia, The, Ghana, Liberia, Madagascar, Malawi, Nigeria, Rwanda, Saudi Arabia, Sierra Leone, South Sudan, Togo, Yemen, Zambia

Manufacturing/Building Method

The product is designed and manufactured in the United Kingdom.

Intellectural Property Type

Patent

User Provision Model

Interested users can email the manufacturer directly for a quote.

Distributions to Date Status

750 devices have been distributed to date Interview with designer, August 2020

Consumables

No

Power supply type

Compressor requires electricity to function and will accept mains power from 90-300 V

Indispensable equipment for function

No

Maintenance or calibration required by user at time of use? (Y/N)

No

Display Type

N/A

Gas Flow Range (L/min)

N/A

Pressure Range (cm H2O)

Internal reservoir pressure is 5 atm (75 psi)

Patient population (specify)

All

Design Specifications

The system consists of two parts: (1) a compressor pump and (2) storage vessels. The compressor consists of a 12 V pump that can be powered from electrical sources between 85 - 290 V. The compressor has three connection ports: inlet from the oxygen concentrator, outlet to the vessel, and the mains power lead connector.

There are two reservoir vessels: a 100 L capacity vessel and a 20 L capacity vessel. The vessels are filled from an oxygen concentrator using a compressor pump, and the oxygen is stored at 5 bar for later use, and the vessels are certified to 10 bar. At 5 bar pressure, the 20 L vessel has a storage of 100 L of oxygen, and the 100 L vessel has a storage of 500 L of oxygen. The vessels are made from aluminum and are cylindrical. The vessels come equipped with a quick release supply fitting and tube. Using an 8 L/min oxygen concentrator, the small vessel can be filled in 15 minutes and the large vessel can be filled in 60 minutes. The vessels can supply an outflow of oxygen until the internal vessel pressure reaches 1.2 bar, whereby an alarm will sound indicating the need to replace the oxygen supply and refill the vessel.

Product dimensions and weight for the 20 L vessel: 25 x 25 x 70 cm, 6 kg

Product dimensions and weight for the 100 L vessel: 40 x 40 x 105 cm, 13.5 kg

Technical Support

Provided by the manufacturer.

Replacement Components

Components will have to be replaced with wear. Components available for replacement can be found in the Oxygen Reservoir Systems product information

Lifecycle

At least 5 years. The first device was deployed 5 years ago and it is still functioning as required. Interview with designer, August 2020

Manufacturer Specified Performance Parameters

Manufacturer specified performance targets include low cost, usable in low/no power settings, easy to use.

Vetted Performance Status

Product testing in Sierra Leone had the following results:

Safety

The compressor pump has several safety features: an overpressure cutoff, flow restrictors to avoid over-demand from the concentrator, and a flame guard fire safety device.

Complementary Technical Systems

Diamedica sells a compressor pump that is compatible with the Oxygen Reservoir Systems and can be used for filling the vessels. The system has standardized adaptors allowing the system to be used with standard hospital equipment.

Academic Research and References

R. P. Rassool, B. A. Sobott, D. J. Peake, B. S. Mutetire, P. P. Moschovis, and J. F. Black, A low-pressure oxygen storage system for oxygen supply in low-resource settings, Respir. Care, vol. 62, no. 12, pp. 1582–1587, Dec. 2017, doi: 10.4187/respcare.05532.

D. McNeil, A Simple Way to Save Lives as Covid-19 Hits Poorer Nations., The New York Times, 2020.

M. Davies, A. Onwuzoo, and S. Mednick, “Fighting for breath: how the medical oxygen industry is failing African hospitals,” The Guardian, 2020.

S. R. C. Howie et al., Meeting oxygen needs in Africa: An options analysis from the Gambia,” Bull. World Health Organ., vol. 87, no. 10, pp. 763–771, Oct. 2009, doi: 10.2471/BLT.08.058370.

Diamedica, “Oxygen Reservoir Systems product information”. 2022

Saint John of God Hospital, “LOW PRESSURE OXYGEN SYSTEM POWERED BY SOLAR ENERGY FOR PAEDIATRIC USES“, 2020

Compliance with regulations

CE certified, ISO 13485 certified

Evaluation methods

The product and facility are evaluated according to ISO 13485 guidelines. Interview with designer, August 2020

Other Information

Winner of the 2017 AAGBI Award for Innovation in Anaesthesia, Critical Care, and Pain.

Agriculture

February 27, 2024

Implemented by

Solar Oxygen

Agriculture

March 8, 2024

Implemented by

Pacific Consolidated Industries

Agriculture

June 6, 2024

Agriculture

December 27, 2023

Implemented by

Aqus

Agriculture

November 30, 2024

Implemented by

KOKO Networks

Agriculture

June 7, 2024

Implemented by

Trice Imaging, Inc

Agriculture

June 22, 2024

Implemented by

The Okoa Project

Agriculture

January 24, 2024

Implemented by

Nanyang Technological University (NTU) Singapore

Agriculture

November 21, 2024

Implemented by

BriteLyt

Agriculture

January 2, 2024

Implemented by

Katadyn Group

Have thoughts on how we can improve?

Give Us Feedback